Scania 6000 Instrumentation en-GB 2 268 512. Operator's manual - part 3

Application modes

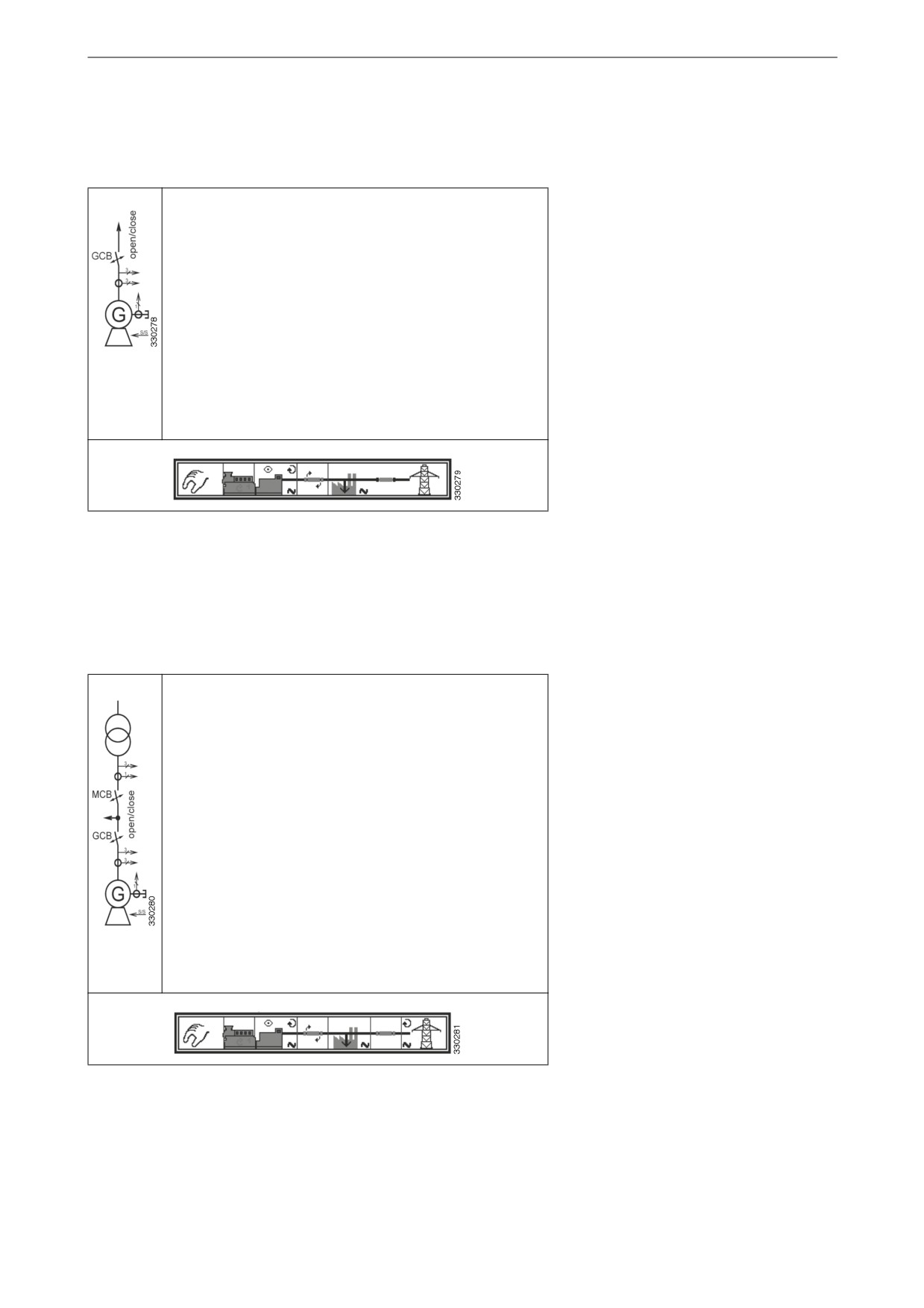

Application mode {1oc}

Application mode {1oc} has the following functions:

• Measurement of engine parameters, and generator

parameters, i.e., voltage, frequency, current, power,

coolant temperature, oil pressure, etc.

• Starting or stopping the engine.

• Engine protection and generator protection in the

form of relay output in the opening of generator set

circuit breakers.

• Relay output for the closure of the generator set cir-

cuit breaker.

• Detection of power failure on normal electrical pow-

er network,

Application mode {2oc}

Application mode {2oc} has the following functions:

• Measurement of engine parameters, and generator

parameters, i.e., voltage, frequency, current, power,

coolant temperature, oil pressure, etc.

• Starting or stopping the engine.

• Engine protection and generator protection in the

form of relay output in the opening of generator set

circuit breakers.

• Relay output for the closure of the generator set cir-

cuit breaker.

• Relay output for opening and closing of the circuit

breaker in the automatic transfer switch.

• Detection of power failure on normal electrical pow-

er network and automatic startup and shutdown of

the engine.

32

Operating modes

Operating modes

Operating mode stop

Note:

Operating mode stop is not the same as an emergency stop. In

some cases the instrument panel carries out additional logic func-

tions, such as an engine cooling-off period before the engine is

turned off. Scania recommends that a digital input for emergency

stop is used and programmed as an alarm of class F.

In the operating mode stop neither the engine or generator set cir-

cuit breakers run. Depending on the application mode, the circuit

breakers cannot be operated.

The following occurs if operating mode stop is se-

lected when the engine is already shut down:

• Generator set circuit breaker does not close.

• The fuel solenoid relay is not activated.

• Commands for the digital inputs and CAN bus are ignored.

• Display buttons for start disabled, depending on previous op-

erating mode.

• The monitoring of the generator set remains disabled, except

for the monitoring that is not dependent on engine speed.

33

Operating modes

The following occurs if the operating mode stop

has been selected when the engine is running

• The circuit breaker in the generator set opens when

- the instrument panel is at least in application mode {1o}

- the circuit breaker in the generator set is closed.

• The circuit breaker in the automatic transfer switch closes

when

- the instrument panel is at least in application mode {2oc}

- the circuit breaker in the generator set is open

- the circuit breaker in the automatic transfer switch is acti-

vated

- the parameter close MCB in stop mode (close the circuit

breaker in the automatic transfer switch in operating mode

stop) is set to YES.

• Engine cooling is performed and the indicator lamp for oper-

ating mode stop flashes.

• The fuel solenoid relay is deactivated.

• The monitoring of the generator set is disabled, except for the

monitoring that is not dependent on engine speed.

• The instrument panel display displays the steps when they are

carried out.

The following occurs if the operating mode stop

has been selected when the engine implements

cooling.

• The cooling is stopped and the engine is turned off.

Note:

If the logic handler function Enable MCB (the circuit breaker in

the automatic transfer switch) (parameter 12923) has the value

true, the circuit breaker in the automatic transfer switch closes

again if it is open in the operating mode stop.

34

Operating modes

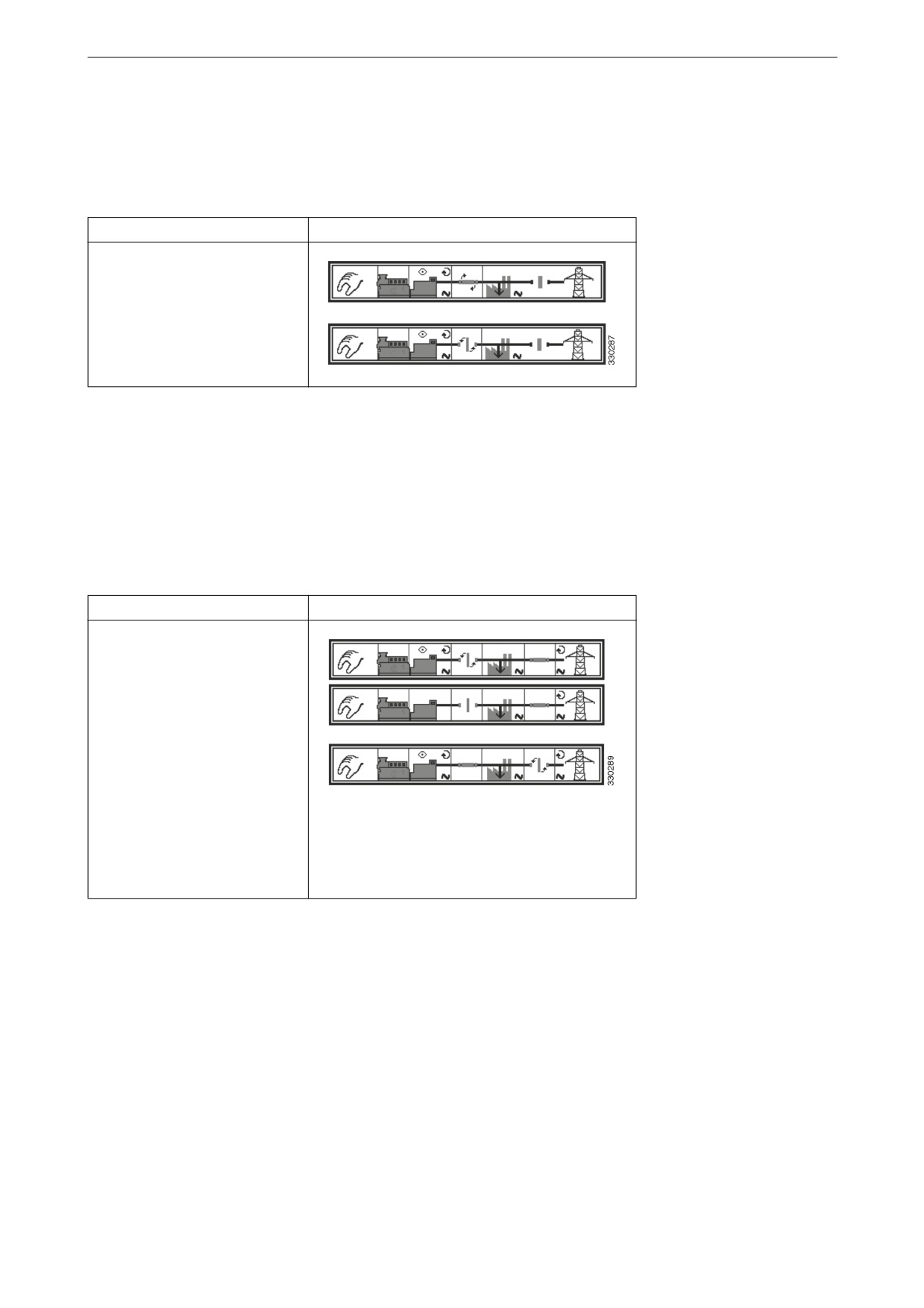

Manual operating mode

In manual operating mode, the engine and the circuit breakers are

operated via the display buttons at the bottom of the view.

Any device that can be operated via the display button has a black

border, others may not be operated. The line diagrams's lowest

line changes according to the application mode.

Line diagram for application mode {0}

For application mode {0} a display button with a black frame is

displayed around the engine to indicate that it is possible to start

and stop the engine.

Example of line diagram

• Start the engine

• Shut off the engine

Line diagram for application mode {1o}

For application mode {1o} display buttons for both the engine

and generator set power circuit breaker are displayed with the fol-

lowing functions.

The symbol X indicates that an open command for the circuit

breaker has been issued and the closing of the circuit breaker has

been blocked. The dotted line indicates no defined status of the

circuit breaker.

Example of line diagram

• Start the engine

• Shut off the engine

• Open the circuit breaker in

the generator set

35

Operating modes

Line diagram for application mode {1oc}

For application mode {1oc} display buttons for both the engine

and generator set power circuit breaker are displayed with the fol-

lowing functions.

Example of line diagram

• Start the engine

• Shut off the engine

• Open the circuit breaker in

the generator set

• Close the circuit breaker in

the generator set

Line diagram for application mode {2oc}

For application mode {2oc} display buttons for the engine, the

circuit breaker in the generator set and the circuit breaker in the

automatic transfer switch are displayed with the following func-

tions:

Example of line diagram

• Start the engine

• Shut off the engine

• Open the circuit breaker in

the generator set

• Close the circuit breaker in

the generator set

• Open the circuit breaker in

the automatic transfer

switch

• Close the circuit breaker in

the automatic transfer

switch

36

Operating modes

Automatic operating mode

In automatic operating mode, all functions of the motor, circuit

breakers in generator sets and automatic transfer switches are op-

erated via a remote start signal, or automatically by the instru-

ment panel, such as during a power failure on the normal

electrical power network.

The function of the instrument panel depends on its configuration

and the external signals used.

The main features are briefly described as follows.

Starting the engine

Remote engine start

The engine is started with a remote start signal.

A remote start requires that:

• Automatic operating mode is enabled.

• The Start req. in AUTO function is assigned to a digital input

via the logic handler and the conditions are met (true).

• The digital input or an external start is activated (logic high

signal ) or the necessary command interface is set on the inter-

face.

• An alarm of class C or higher is not present.

• The engine is ready for operation.

• Generator set circuit breaker is open.

37

Operating modes

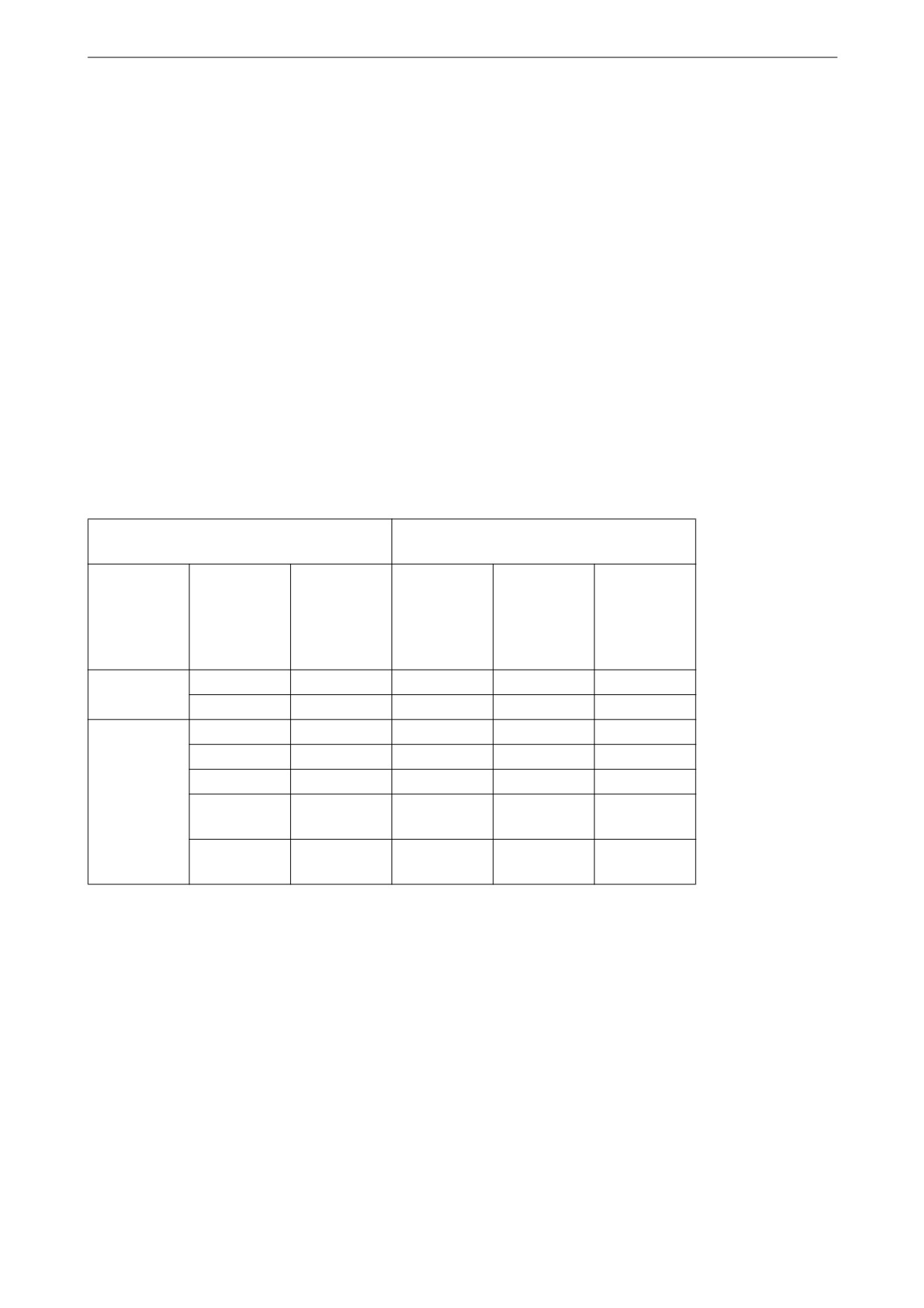

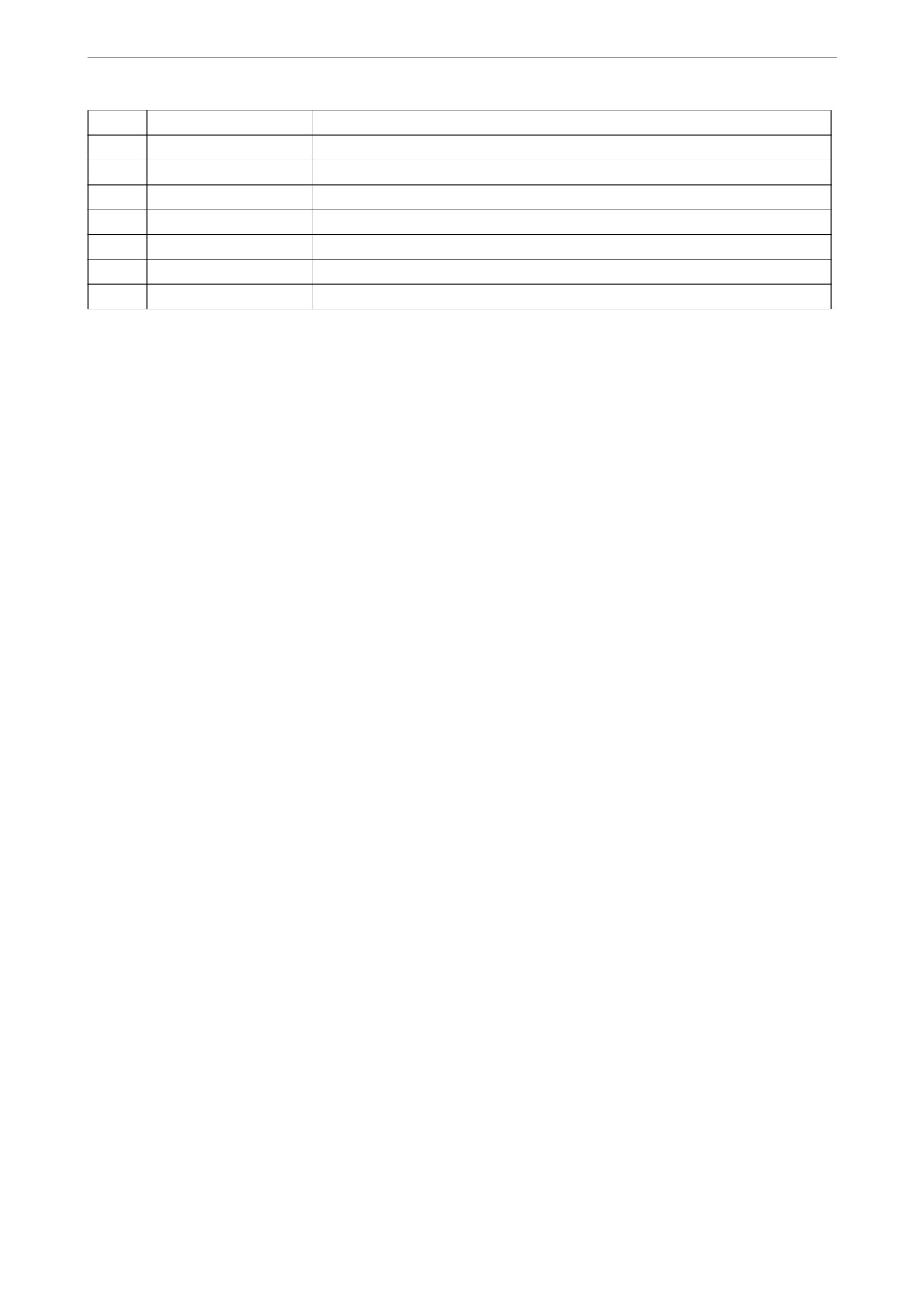

Power failure

Automatic operation during a power failure on the normal elec-

trical power network.

If the automatic operating mode is enabled, the application mode

is {2oc} and a power failure on the normal electrical power net-

work is detected, the engine and the circuit breakers are operated

in accordance with the conditions in the table below.

An automatic start require that:

• Automatic operating mode is enabled.

• Application Mode is configured as {2oc}.

• The Emergency power parameter is configured.

• The configured limits for power failure on the normal electri-

cal power network is reached.

• The configured delay times have expired.

• An alarm of class C or higher is not present.

• The engine is ready for operation.

Status before detected power failure on

Measure in order

the normal electrical power network

Engine

Circuit

Circuit

Engine

Circuit

Circuit

breaker in

breaker in

breaker in

breaker in

the genera-

the auto-

the genera-

the auto-

tor set

matic trans-

tor set

matic trans-

fer switch

fer switch

0 (switched

0 (opened)

0 (opened)

1 (start)

2 (closes)

off)

0 (opened)

1 (closed)

1 (start)

3 (closes)

2 (opens)

1 (running)

0 (opened)

0 (opened)

--

1 (closes)

0 (opened)

1 (closed)

--

2 (closes)

1 (opens)

1 (closed)

0 (opened)

--

--

--

1 (closed)

1 (closed)

--

1 (opens)3

2 (closes)

(closes)

1 (closed)

1 (closed)

--

(remains

1 (opens)

closed)

38

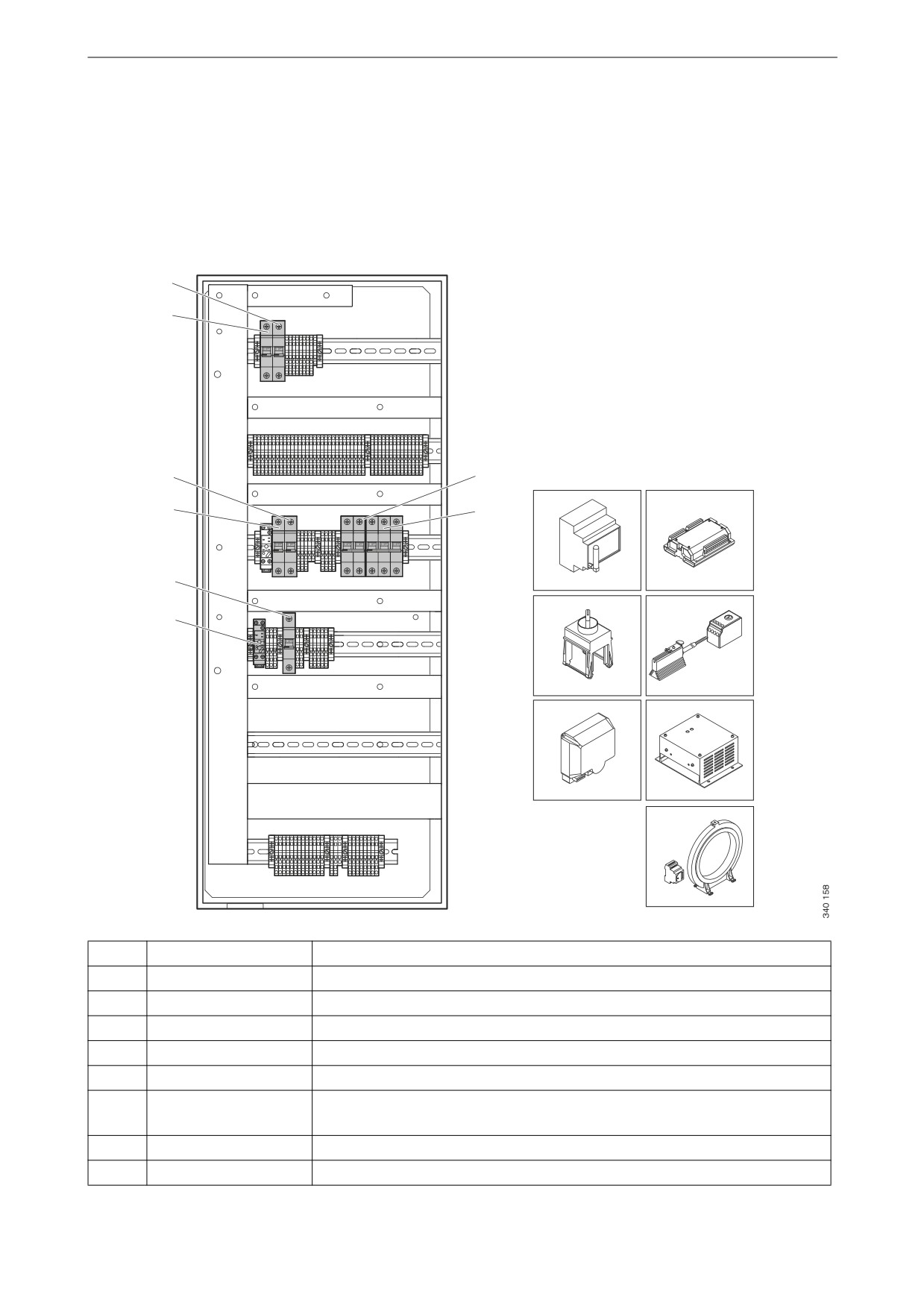

Components in the central electric unit

Components in the central electric

unit

The illustration below shows the location of the components in-

side the central electric unit. The figure shows all options, and the

central electric unit ordered can therefore have other equipment.

1

2

3

7

9

10

4

8

5

11

12

6

13

14

15

Pos.

Designation

Description

1

MCB2

Miniature circuit breaker for instrument panel, 10 A

2

MCB1

Miniature circuit breaker for engine control unit, 20 A

3

MCB3

Miniature circuit breaker for coolant heater, 10 A

4

MCB6

Miniature circuit breaker for battery charger, 6 A

5

MCB4

Miniature circuit breaker for instrument panel heating element, 2 A

6

HCR

Relay for engine heater, instrument panel heater element and generator

heater

7

MCB

Miniature circuit breakers for load voltage

8

MCB

Miniature circuit breakers for mains voltage

39

Components in the central electric unit

Pos.

Designation

Description

9

Netbiter WS200

Communication unit for remote connection

10

Expansion unit

16 additional inputs and outputs

11

Switch

For changing between 50/60 Hz

12

OH2/FLZ510

Heater element for instrument panel/thermostat

13

Battery charger

For 110 V electrical power network

14

Battery charger

For 220/240 V electrical power network

15

Hobut

Residual current device

40