Scania DC13 PDE. Industrial engine en-GB 2 823 973. Operator’s manual - part 5

Other

WARNING!

Block the starting device. If the engine starts un-

expectedly, there is a serious risk of injury.

IMPORTANT!

The engine must be cold when the work is car-

ried out.

Remember to remove the turning tool from the

flywheel after adjustment.

Note:

Carry out the working without pausing, so that

no step is overlooked.

Carry out a check and adjustment of the valve

clearances and the unit injectors one more time

after the first 500 hours of operation. After this,

adjustment according to the regular interval

takes place, which is every 2,000 operational

Upper and lower window to read the engraving on

hours.

the flywheel.

The reference information UP TDC, DOWN

TDC and the angle indications listed in the table

below are engraved on the flywheel. Depending

on the engine installation, this information is vis-

ible in one of the windows, either furthest up or

furthest down on the flywheel. See illustration.

1

2

3

4

5

6

Order of cylinders.

64

Other

Workflow table

Adjust valves and injectors according to the table

below. Follow the respective column depending

on whether you are reading the engraving on the

flywheel in the lower or the upper window. Start

adjustment at the top of the table.

Reading in the low-

Valve transition on

Adjust valves on

Adjust injector on

Reading in the up-

er window

cylinder

cylinder

cylinder

per window

DOWN TDC

1

6

2

UP TDC

120/480

5

2

4

300/660

240/600

3

4

1

60/420

DOWN TDC

6

1

5

UP TDC

120/480

2

5

3

300/660

240/600

4

3

6

60/420

65

Other

Checking and adjusting the valve

clearance

Valve clearance, specifications

Intake valve

0.45 mm (0.018 in)

Exhaust valve

0.70 mm (0.028 in)

Tightening torque

Lock nut for valves

35 Nm (26 lb/ft)

1. Clean the rocker covers and the area around

them.

2. Remove the rocker covers.

3. Use the turning tool appropriate to the instal-

lation of the engine. Tool 99 309 is used to

rotate the flywheel from the underside of the

engine and tool 2 402 509 is used from the

top side.

4. Start adjusting one cylinder according to the

table. Rotate the flywheel until the correct

engraving can be read on the flywheel. It

may be necessary to rotate it more than 1 rev-

olution.

Rotate the flywheel in the rotational direc-

tion of the engine, which is clockwise

viewed from the front of the engine and anti-

3

clockwise viewed from the back of the en-

gine.

During a valve transition, the exhaust valve

(the long arm) is closing at the same time as

4

the intake valve is opening.

The UP TDC engraving on the flywheel is

now visible in the window furthest up on the

flywheel. The DOWN TDC engraving is vis-

5

ible in the lower window.

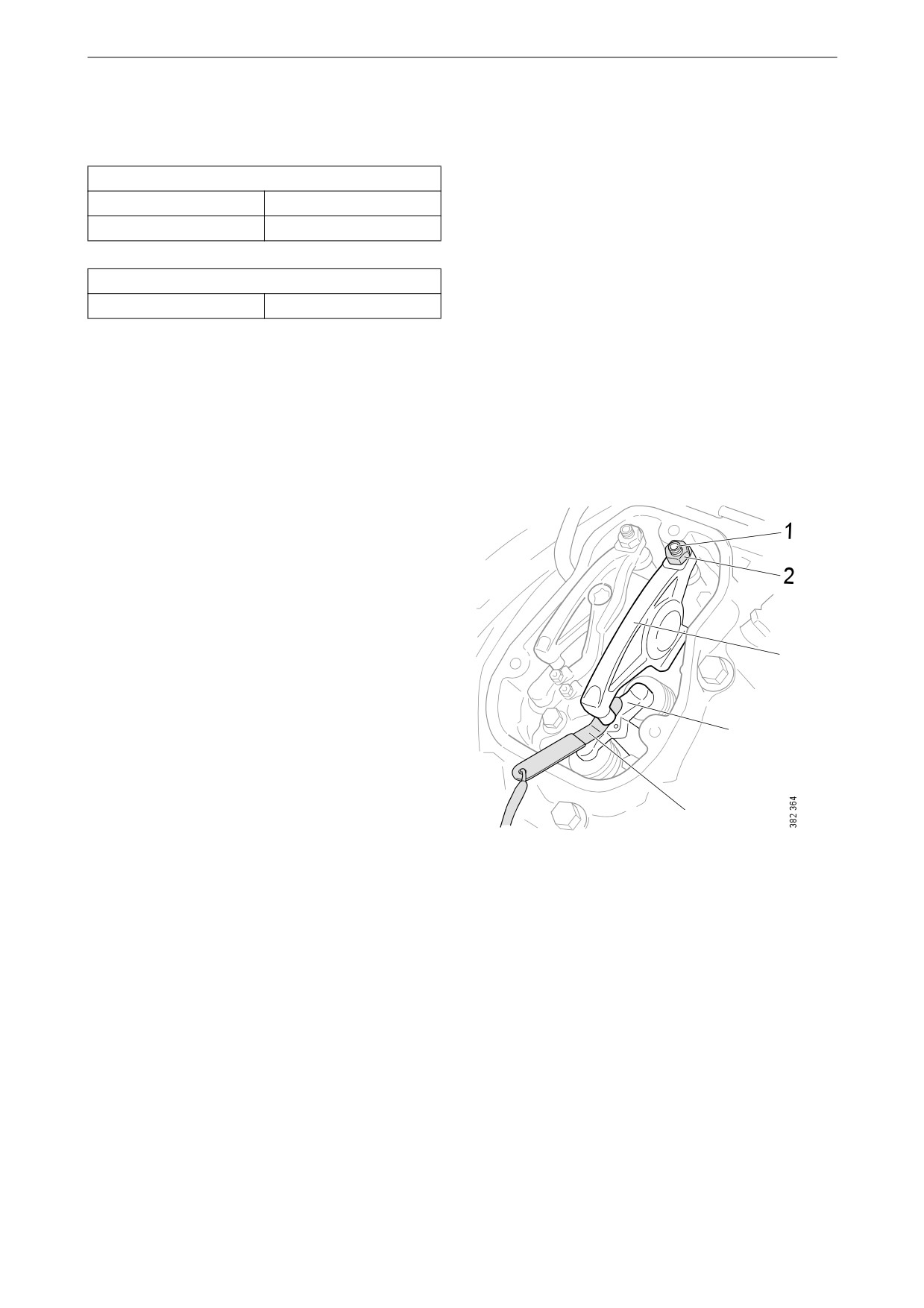

1. Adjusting screw.

5. Read Workflow table on the previous page to

2. Lock nut.

see which valve to adjust.

6. Stick the feeler gauge under the pressure pad

3. Rocker arm.

of the rocker arm and check the valve clear-

4. Valve bridge.

ance.

5. Feeler gauge.

7. If necessary, adjust the valve clearance by

a) loosening the lock nut on the end of the

rocker arm

b) adjusting the valve clearance with the ad-

justing screw

c) tightening the lock nut.

8. Mark the rocker arm with the felt-tip pen and

adjust the unit injector according to the next

section. Then continue on to the next cylin-

der according to the table.

66

Other

Checking and adjusting the unit in-

jectors

Tightening torque

Lock nut for unit injec-

39 Nm (29 lb/ft)

tors

1. See the Workflow table for details of the in-

jectors to be adjusted.

2. Fit the setting tool with the metal plate

around the unit injector.

The unit injector is correctly set when the

3

2

small piston (1) is level with the flat upper

surface of the tool. Use a finger to check.

You can feel very small differences. See also

the illustrations on the next page.

3. If necessary, adjust the unit injector by

a) loosening the lock nut (2)

b) adjusting the unit injector using the adjust-

ing screw (3)

c) tightening the lock nut.

IMPORTANT!

Remove the setting tool when the adjustment is

done.

4. Mark the injector with the felt-tip pen and

1

continue adjustment according to the table.

67

Other

The setting tool piston is above or below the flat

The setting tool piston is level with the flat upper

upper surface of the tool. Adjust the unit injector. surface of the tool. The unit injector is correctly

adjusted.

68

Quality requirements for fuel

Quality requirements for

fuel

Quality requirements and testing standards for

the most important properties of different types

of fuel are described in the Workshop Manual.

This can be ordered from Scania dealers or di-

rectly from Scania.

Diesel

Properties

The quality of the diesel is very important for the

operation and service life of the engine and the

fuel system, and also for the engine performance.

REQUIREMENT!

The diesel should comply with the requirements

of European standards EN590 or EN15940.

However, Scania accepts larger tolerances of

certain properties. Please see the table below.

Properties

Requirements

Viscosity at 40°C

1.4-4.5 cSt

(104°F)

Density at 15°C (59°F)

0.79-0.87 kg/dm3

Ignitability (CET rating)

minimum 49

Lowest flashpoint

56°C (132°F)

Particulate contamina-

Classification 22/20/17

tion level

according to ISO 4406

69

Quality requirements for fuel

Permitted sulphur content in diesel

IMPORTANT!

The operator is responsible for using the correct

type of diesel to ensure that local laws are com-

plied with.

Engine type

Max. sulphur content

Remark

Engines without EGR sys-

4,000 ppm (0.4%)

If the sulphur content is higher than 2,000 ppm, the

tem

oil change intervals must be halved. A higher sul-

phur content than 4,000 ppm is not permitted, since

this will result in engine damage.

Engines with EGR system

350 ppm (0.035%)

If diesel with too high a sulphur content is used,

this causes engine damage.

Temperature dependence of diesel

IMPORTANT!

Mixing kerosene or other paraffins with the die-

sel is prohibited. The injectors may be damaged.

It is not permissible to mix petrol with diesel. In

the long term petrol can cause wear in the injec-

tors and engine.

At temperatures lower than those specified for

the diesel, paraffin wax may precipitate from the

diesel and block filters and pipes. The engine can

then lose power or stop.

The diesel is adapted for use in the specific cli-

mate of each country. If an engine is to be oper-

ated in a temperature zone with a temperature

lower than normal, first identify the temperature

properties of that particular diesel.

70

Quality requirements for fuel

Use of fuel oil in stand-by generator sets

Long-term storage of diesel, where the diesel

comes into contact with water, may lead to the

growth of micro organisms (bacteria and fun-

gus). To avoid this in fuel used in stand-by gen-

erator sets, Scania permits the use of fuel oil

according to DIN 51603-1 and

ÖNORM C 1109.

Use of fuel oil is only permitted for stand-by

generator sets and under the following condi-

tions:

• The fuel must not be stored or used in temper-

atures under -10°C (14°F).

• The engine must not be equipped with an

SCR system.

71

Quality requirements for fuel

Biodiesel (FAME)

Use of biodiesel

IMPORTANT!

Engine types DC16 084A and DC16 091A are

approved for used with biofuel in accordance

with ASTM D7467 (up to 20% mixture of bio-

diesel).

For other engines, a maximum of 10% mixture

of biodiesel should be used.

Note that reduction of maintenance intervals ap-

plies for use of more than 10% biodiesel.

Scania uses the term biodiesel to refer to a re-

newable diesel made from greases or oils and

methanol. The biodiesel should conform to the

requirements of European standard EN 14214 or

Brazilian standard ANP-45. For biodiesel in ac-

cordance with EN 14214 or ANP-45, the generic

term FAME is frequently used.

Normal diesel in accordance with EN 590 can

contain up to 7% biodiesel from the diesel sup-

plier. There are grades of diesel that comply with

EN 590 but contain a higher mixture of biodies-

el.

For PDE engines, Scania approves the use of up

to 100% biodiesel in accordance with EN 14214

or ANP-45.

Maintenance interval

IMPORTANT!

Make sure that maintenance intervals are differ-

ent when operating on diesel or biodiesel.

With a greater mixture of biodiesel than 10%, the

renewal intervals for the following are halved:

• Fuel filter.

• Oil filter.

• Engine oil.

The viscosity grade of the engine oil should be

xW-40. xW-30 grade oils are unsuitable due to

the fuel dilution effect.

The engine oil level must be checked regularly.

If the oil level exceeds the maximum level, the

oil must be changed.

72

Quality requirements for fuel

The water separating prefilter must be checked

regularly in order to prevent water ingress into

the fuel system.

When using biodiesel, the EGR cooler may also

need to be cleaned.

Storage of biodiesel

IMPORTANT!

Biodiesel must not be stored for more than 6

months.

Biodiesel has a maximum storage life of

6 months from the date of production to the ex-

piry date. The fuel is affected by light, tempera-

ture, water, etc. during storage, which affects the

fuel characteristics and durability.

Biodiesel also has lower stability against oxida-

tion than diesel. This can result in a thickening of

the fuel and blocking of parts of the fuel system,

e.g. the fuel filter. Bacterial growth can occur

when biodiesel is stored in a tank in unfavoura-

ble conditions. Avoid storage in barrels or auxil-

iary tanks, except when fuel turnover rates are

high. Check tank cleanliness whenever refuel-

ling takes place.

If the engine has been refuelled with biodiesel,

and is stationary for a long period, condensation

water can form in the fuel tank resulting in bac-

terial growth.

See also the section Preservative fuel.

73

Quality requirements for fuel

HVO

HVO is a synthetic diesel which is manufactured

through the hydrogenation of plants and animal

fats. To the user, HVO is reminiscent of diesel in

accordance with EN590, apart from HVO having

a somewhat lower density.

Scania approves the use of up to 100% HVO for

all engines in accordance with the European

standard EN 15940.

GTL

GTL is a synthetic fuel that is often refined from

natural gas. To the user, GTL is reminiscent of

diesel in accordance with EN590, apart from

GTL having a somewhat lower density and less

odour.

Scania approves the use of up to 100% GTL in

accordance with the European standard EN

15940.

74

Preparing the engine for storage

Preparing the engine for

storage

If the engine is not being used for an extended

period its cooling system, fuel system and com-

bustion chamber and outside must be protected

against rust.

The engine can normally stand idle for up to

6 months without needing preparation. For

longer periods of than 6 months, however, the

measures in the following sections must be tak-

en. These measures provide protection for ap-

proximately 3 years, then the preparing

procedure must be repeated. An alternative to

preparing the engine for long-term storage is to

start the engine and warm it up every 6 months.

Preparation means that the following measures

are taken:

• The engine is cleaned thoroughly.

• Run the engine for a specific period using

special preservative fuel, oil and coolant.

• Otherwise prepare the engine for storage (fil-

ter renewal, lubrication, etc.).

Preservative products

Preservative oil

Use a normal engine oil that meets the require-

ments in the Oil grade section.

75

Preparing the engine for storage

Preservative coolant

Use coolant containing 50% by volume of gly-

col. Example: BASF MPG Glysacorr P113 and

Valvoline Zerex P113 FP.

WARNING!

Ethylene glycol can be fatal if ingested and can

cause skin irritation and eye damage.

Preservative fuel

Preservative fuel must not contain biodiesel.

Even small amounts of 5-10% biodiesel can have

adverse effects on the engine when in longterm

storage.

Long-term storage of diesel, where the diesel

comes into contact with water, may lead to the

growth of micro organisms (bacteria and fun-

gus).

In order to minimise the growth of micro-organ-

isms, preservative fuel should contain the fol-

lowing additives. The additives should be

selected and added by the fuel supplier.

Preservative fuel should comply with the follow-

ing requirements:

•

0% biodiesel.

•

Max. sulphur content 50 ppm.

•

Max. water content 200 ppm.

•

The fuel must contain additives to stop the

growth of micro-organisms.

76

Preparing the engine for storage

Preparations for storage

Environment

Use a suitable container. Used oil and coolant

must be disposed of as specified in national and

international laws and regulations.

Note:

Do not remove the injectors.

1. Remove plugs and tape from the coolant

connections, air intake and exhaust pipe.

2. Drain the oil.

3. Renew the oil filter and fuel filter.

4. Clean the centrifugal oil cleaner.

5. Fill with engine oil to the minimum level on

the oil dipstick.

6. Drain and flush the cooling system of any old

coolant.

7. Top up with preservative coolant.

8. Mix preservative fuel in a can. Detach the

fuel pipe at the feed pump suction line and

connect a hose from the can.

9. Detach the fuel pipe at the overflow valve

and connect a return hose to a separate can.

10. Connect and bleed the fuel system.

11. Start the engine and run it at about 1,100 rpm

for 20 minutes.

12. Remove the rocker covers and lubricate the

valve mechanisms with pushrods and the

valve tappets, as well as the injector mecha-

nism, using a liberal amount of preservative

oil. Refit the rocker covers.

13. Drain the coolant if the engine is not to be

stored with coolant in the system. Plug and

tape all coolant connections if the engine is

to be stored without coolant in the cooling

system.

14. Renew the filter element in the air cleaner.

15. Cover the air intake and exhaust pipe.

16. Spray the outside of the alternator and starter

motor with water-repellent anti-corrosive

oil: CRC 226, LPS1 or equivalent.

17. Spray the outside of bright engine parts, first

with penetrating preservative oil such as

Dinitrol 25B and then with Dinitrol 112 or

the equivalent.

77

Preparing the engine for storage

18. Clearly mark the engine with the storage

preparation date, and state that the engine

must not be started or cranked.

Batteries

WARNING!

Wear protective gloves and protective goggles

when charging and handling batteries. The bat-

teries contain a highly corrosive acid.

Remove the batteries and trickle charge them at

the battery charging station. This does not apply

to batteries specified as maintenance-free by the

manufacturer.

The same applies to short-term storage, even if

the engine has not been prepared for storage as

above.

Storage

After the preparation, the engine should be

stored indoors in a dry location at room temper-

ature. The engine must be packed in packaging

made of VCI plastic to protect against dust, dirt

and moisture.

When the engine is to be taken into

operation again

1. Remove plugs and tape from the coolant

connections, air intake and exhaust pipe.

2. Fill the cooling system with coolant.

3. Drain the preservative oil.

4. Renew the oil filter and fuel filter.

5. Fill with new engine oil.

6. Remove the rocker covers and lubricate the

valve mechanisms with pushrods and the

valve tappets, as well as the injector mecha-

nism, using a liberal amount of oil. Refit the

rocker covers.

7. Drain the preservative fuel from the fuel

manifold.

8. Connect and bleed the fuel system.

9. Wash off any preservative oil on the outside

using white spirit.

78

Technical data

Technical data

General data

Number of cylinders and configuration

6, straight

Working principle

4-stroke engine

Cylinder diameter (mm/in)

130/5.12

Piston stroke (mm/in)

160/6.30

12.7/775.0

Displacement (dm3/in3)

Firing sequence

1 - 5 - 3 - 6 - 2 - 4

Compression ratio

17.3:1

Engine direction of rotation viewed from rear

Anti-clockwise

Fan direction of rotation viewed from front

Clockwise

Cooling

Coolant

Valve clearances, cold engine:

Intake valve (mm/in)

0.45/0.02

Exhaust valve (mm/in)

0.70/0.03

Number of teeth on the flywheel

158

Low idling speed (rpm)

500-975

Maximum full-load speed (rpm)

1,800/2,100

Fuel

Diesel

Approximate weight, without coolant and oil (kg/lb)

1,050/2,315

Lubrication system

Oil volume

See Maintenance

Oil cleaning

Centrifugal oil cleaning

Oil cooler

Coolant cooled, full flow

Oil filter

Paper filter from Scania

Interval between oil changes (h)

500

Oil pressure (bar/psi)

Normal with the engine at operating temperature, operating speed

3-6/43.5-87

Minimum permitted at idling speed

0.7/10.2

Crankcase pressure with closed crankcase ventilation (mbar/psi)

-5.4 to 2.0/-0.08 to 0.03

79