Scania DC13 PDE. Industrial engine en-GB 2 823 973. Operator’s manual - part 4

Cooling system

Cleaning the cooling system

Note:

Clean the cooling system more often than speci-

fied in the maintenance interval if necessary.

External: Cleaning the radiator and

charge air cooler

IMPORTANT!

Do not use caustic soda or other alkaline deter-

gent as this could damage the aluminium.

Read the warning text on the detergent packag-

ing.

1. Check that the radiator and the charge air

cooler are not clogged on the air side and that

the cooling fins are not damaged.

2. Carefully scrape away any deposits from the

radiator cooling fins. Use a paraffin-based

engine cleaner if necessary.

3. Carefully straighten bent cooling fins using a

steel brush or the like.

48

Cooling system

Internal: Removing oil and grease

Environment

Use a suitable container. Used coolant must be

disposed of as specified in national and interna-

tional laws and regulations.

Always fit a new thermostat and a new cover to

the expansion tank after cleaning, as the oil in the

cooling system destroys the seals. If the engine is

equipped with a coolant filter, also renew this fil-

ter.

It may be necessary to wash it multiple times if

the cooling system is very dirty. One cause of

contamination can be that oil is lying on top of

the coolant and collecting high up in the cooling

system. If several rinses are needed, this is not

necessarily because work has been carried out

incorrectly. Oil residues often need to be rinsed

repeatedly from the expansion tank and the ex-

ternal heating system to be completely clean.

Repeated washing is more effective and prefera-

ble to using higher concentrations of detergent

(max. 10%) or cleaning for a longer period (max

30 minutes).

If only a small amount of dirt has collected in the

expansion tank after cleaning, one extra rinse

and clean of the expansion tank only is usually

sufficient. There is no need to clean the whole

cooling system again.

1. Run the engine until it has reached operating

temperature and then drain the cooling sys-

tem following the previous description.

2. Remove the thermostats.

49

Cooling system

3. Fill the cooling system with clean hot water

Internal: Removing deposits

mixed with detergent 2 479 017. Detergent

2 479 017 must make up 5-10% (depending

Environment

on the degree of dirt) of the total coolant vol-

ume.

Use a suitable container. Used coolant must be

If detergent 2 479 017 is not available, use a

disposed of as specified in national and interna-

dishwasher detergent for household dish-

tional laws and regulations.

washers that does not foam. Concentration

1%.

1. Run the engine until it has reached operating

4. Run the engine until it has reached operating

temperature and then drain the cooling sys-

temperature for approximately 20-30 min-

tem following the previous description.

utes. Remember to switch on the cab heating

system, if one is installed.

2. Remove the thermostats.

5. Drain the cooling system.

3. Fill the cooling system with clean, hot water

mixed with radiator detergent which is based

6. Fill the cooling system with clean, hot water

on sulphamic acid and contains dispersing

and run the engine for about 20-30 minutes.

agents. Follow the manufacturer's instruc-

7. Repeat steps 3-6 if the cooling system is not

tions for the concentration and cleaning peri-

clean.

od.

8. Drain the water from the cooling system.

4. Run the engine for the specified time. Re-

9. If necessary, clean the expansion tank by de-

member to switch on the cab heating system,

taching all hoses and rinsing and cleaning

if one is installed.

with a degreasing agent and a dishwashing

5. Drain the cooling system.

brush.

6. Fill the cooling system with clean, hot water

Alternatively, dismantle the expansion tank

and run the engine for about 20-30 minutes.

and clean it with water with 10% of detergent

7. Drain the water from the cooling system.

2 479 017. Fill the expansion tank with the

mixture, shake it and drain it. Renew the cov-

8. Refit the thermostats.

er of the expansion tank.

9. Fill the cooling system with new coolant as

10. Refit the thermostats.

described in the next section.

11. Fill the cooling system with new coolant as

described in the next section.

12. Check again whether further dirt or oil has

collected in the expansion tank. Decide

whether it it is necessary to carry out another

full cleaning or whether only rinsing or

cleaning of the expansion tank will suffice.

50

Cooling system

Filling coolant

These procedures apply when the cooling system

has been drained and needs to be filled with a

large amount of coolant.

WARNING!

Use protective gloves as coolant can cause irrita-

tion if it comes in contact with the skin. Hot cool-

ant can also cause scalding.

IMPORTANT!

Mix the coolant as specified in the section head-

ed Coolant.

Never fill a large amount of cold coolant in a hot

engine. There is great risk of cracks forming in

the cylinder block and cylinder heads.

Do not start the engine until the correct coolant

level has been obtained. If the engine is started

with an insufficient coolant level, it can damage

the coolant pump shaft seal, which leads to cool-

ant leakage.

51

Cooling system

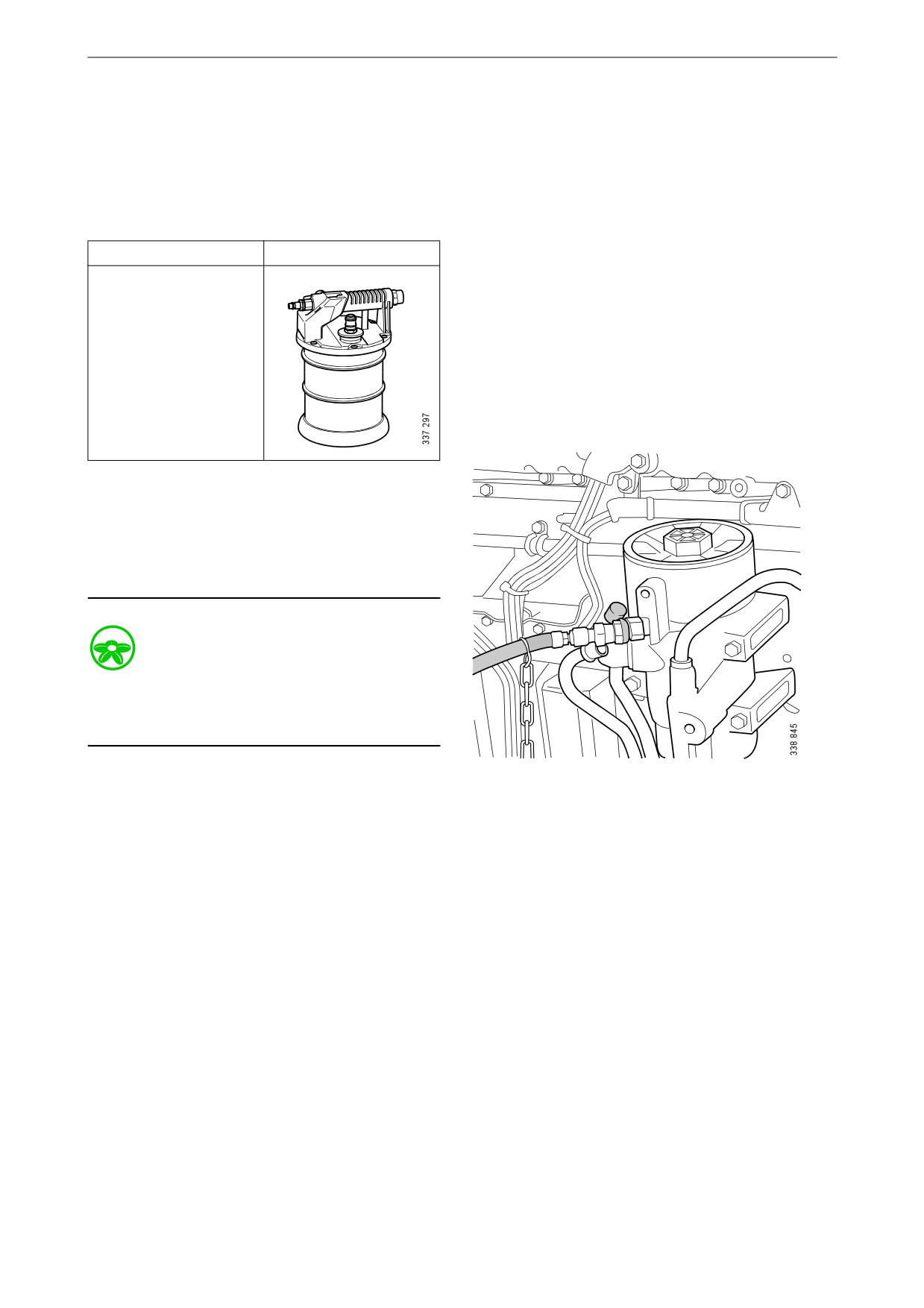

Filling coolant with coolant pump

Special tool

Number, designation

Illustration

2 443 679, coolant

pump

1. Open the expansion tank cap.

2. Connect the coolant pump to the filler nipple

in the cylinder block. See illustration.

3. Connect the pump's 2 cable terminals to the

battery's negative and positive terminal.

Make sure that the filling starts. If the filling

does not start: Change the position of the ca-

ble terminals.

4. Start the engine and run it at idling for

15 minutes.

IMPORTANT!

It is very important that the engine is idling. En-

gine overspeed could damage the coolant pump

shaft seal, which leads to coolant leakage.

5. Switch off the engine and fill with coolant to

the maximum level through the expansion

tank.

Air pockets may still be left in the cooling sys-

tem. These will disappear after the engine has

been operated for a period of time. Therefore, the

coolant may need topping up at a later stage.

52

Cooling system

Refilling coolant with coolant trolley

Tools

Designation

Illustration

588 540 Coolant trolley

99 301 Adapter

1. Open the expansion tank cap.

2. Connect the coolant trolley to the filler nip-

ple in the cylinder block. See illustration.

The adapter must be used when using the

trolley.

3. Fill with coolant using coolant trolley to

pump up to the maximum level of the expan-

sion tank.

4. Disconnect the coolant trolley.

5. Start the engine and run it at idling for

15 minutes.

IMPORTANT!

It is very important that the engine is idling. En-

gine overspeed could damage the coolant pump

shaft seal, which leads to coolant leakage.

6. Switch off the engine and fill with coolant to

the maximum level through the expansion

tank.

Air pockets may still be left in the cooling sys-

tem. These will disappear after the engine has

been operated for a period of time. Therefore, the

coolant may need topping up at a later stage.

After filling, it may be good to start the engine

and check that no coolant leakage occurs.

53

Fuel system

Fuel system

Checking the fuel level

Check the fuel level and top up with fuel as nec-

Cleanliness requirements

essary.

Note:

IMPORTANT!

If the fuel tank has been run dry or if the engine

has not been used for a long time, bleed the fuel

The whole fuel system is very sensitive to dirt

system. See the section Bleeding the fuel system.

and even very small particles. Foreign particles

in the system can cause serious malfunctions. It

is therefore very important that everything is as

clean as possible when work is carried out on the

fuel system. Before repair work, the engine must

be washed. If possible, a hot water wash should

be used.

It is strictly forbidden to carry out any machining

work or work with compressed air near an open

fuel system.

Be extra careful and always use clean, lint-free

and dust-free clothes and gloves when working

on the fuel system. Scania recommends using

Tegera 848 gloves.

Clean tools before they are used and do not use

any worn or chrome-plated tools. Material and

flakes of chrome may come off.

Clean connections and the surrounding area be-

fore removal. When cleaning, cloths or paper

which shed fibres must not be used. Use clean

and lint free cloths, part number 588 879.

Plug or cover the connections during removal.

Also clean the connections before the compo-

nents are fitted. Place removed components on a

thoroughly cleaned, dust-free surface. Scania

recommends using a stainless steel bench top,

part number 2 403 296. Cover the components

with a lint free cloth.

54

Fuel system

Renewing the water separat-

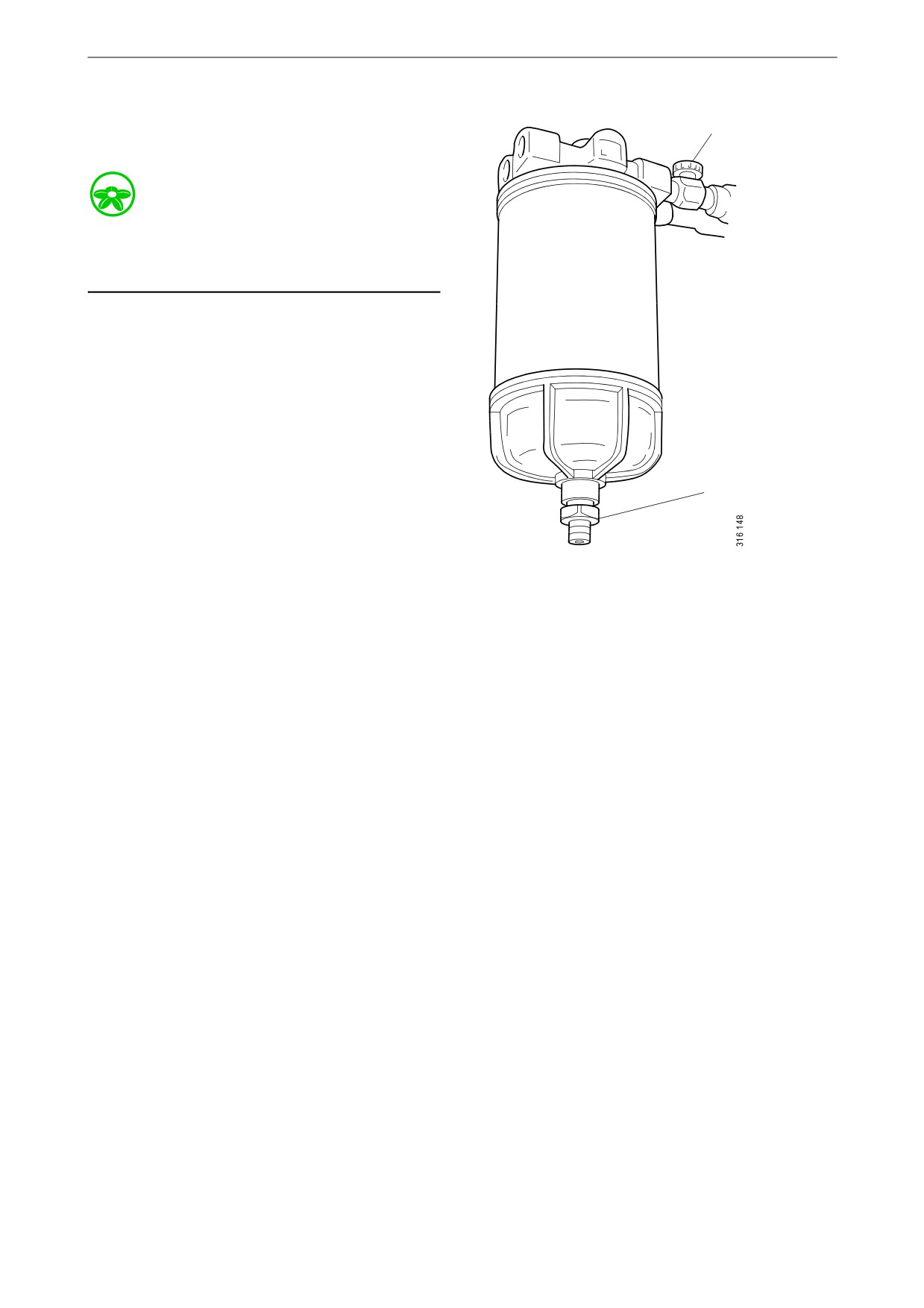

1

ing prefilter

Environment

Use a suitable container. The fuel collected must

be disposed of as specified in national and inter-

national laws and regulations.

Before starting work: Close the shut-off cock in

the fuel pipe, if there is one, and position a con-

tainer under the filter.

1. Open the drain tap on the filter cover and let

the fluid run down into the container.

2. Unscrew the filter cover.

3. Unscrew the filter from the filter head.

2

4. Discard the old filter and use a new filter.

5. Lubricate the O-ring in the filter cover with

engine oil.

6. Screw the filter cover onto the new filter by

1. Shut-off cock

hand. Make sure that the drain tap is fully

2. Drain tap

closed.

7. Lubricate the O-ring on the filter with engine

oil.

8. Fill the width of the filter with clean fuel.

9. Screw the filter into position until the O-ring

rests against the filter head. Tighten the filter

another 1/2 to 3/4 turn by hand.

10. Open the shut-off cock and check the system

for leaks.

11. Bleed the fuel system as per the following

section.

55

Fuel system

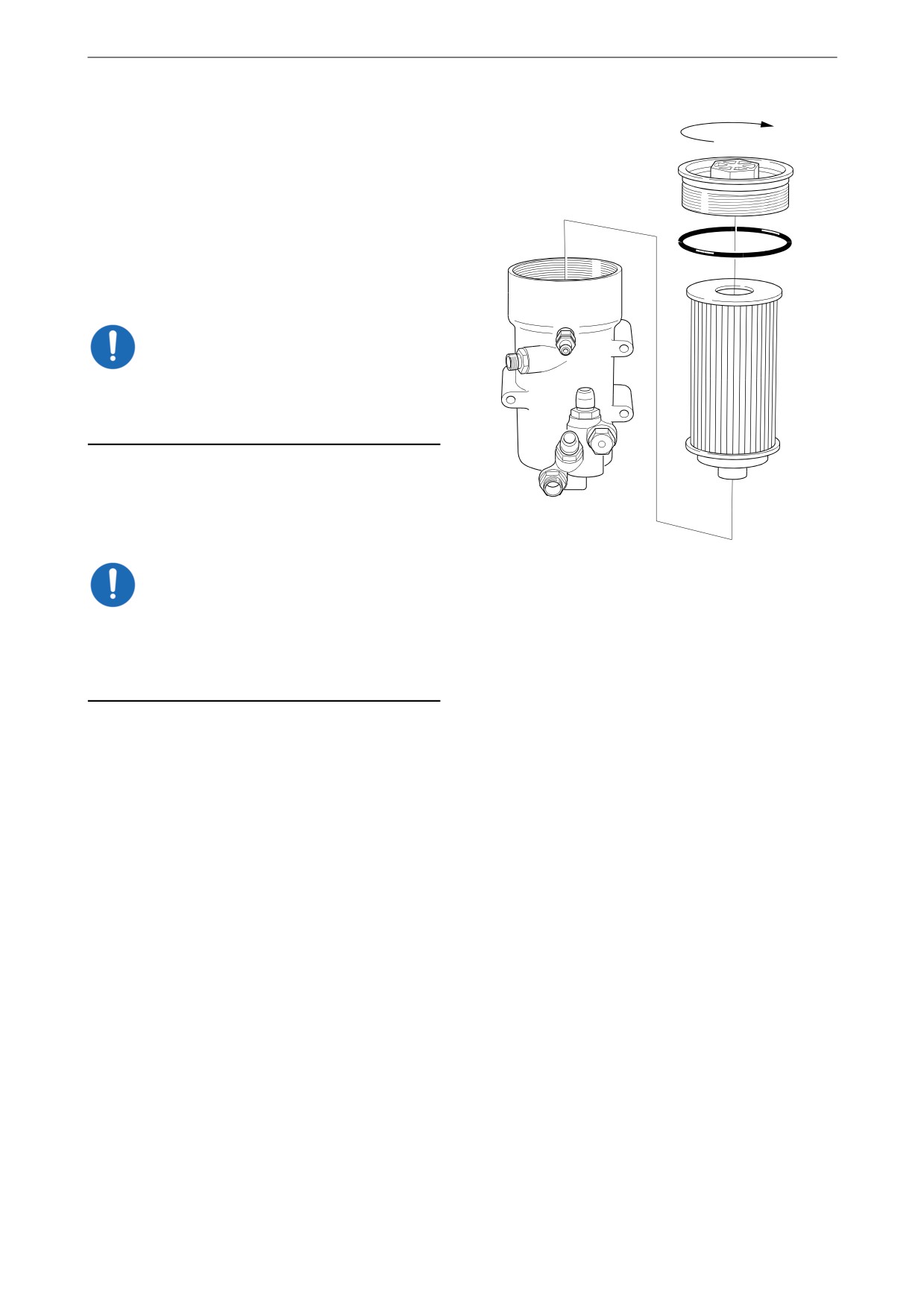

Renewing the fuel filter

Tools

Designation

Illustration

Hexagon socket, 1/2",

36 mm

Environment

Use a suitable container. The fuel collected must

be disposed of as specified in national and inter-

national laws and regulations.

Before starting work: Close the shut-off cock in

the fuel pipe, if there is one, and position a con-

tainer under the filter.

25 Nm

1. Open the bleed nipple on the fuel filter hous-

ing to release any remaining pressure. It may

be difficult to unscrew the filter cover if the

system pressure has not fallen enough.

2. Unscrew the filter cover with the socket.

IMPORTANT!

Do not use an adjustable spanner or other open

tool, as there is a risk of damaging the filter cov-

er.

3. Lift the filter cover with filter element out of

the fuel filter housing. The fuel filter housing

will drain automatically (slowly) once the

filter element has been removed.

IMPORTANT!

If draining is not working, the remaining fuel

should be removed.

56

Fuel system

4. Unscrew the overflow valve and blow the

25 Nm

strainer in the filter housing clean. Also wipe

the bottom of the filter housing.

5. Undo the old filter element from the cover by

carefully bending it to one side.

6. Fit a new O-ring on the cover. Lubricate the

O-ring with O-ring grease.

7. Press a new filter element into the snap fas-

tener in the cover.

IMPORTANT!

Fit the filter element into the cover before plac-

ing it in the fuel filter housing or the filter ele-

ment might be damaged.

8. Press down the filter element into the hous-

ing with the cover. Screw on the filter cover

firmly with the socket. Tightening torque

25 Nm (18 lb-ft).

IMPORTANT!

Screw on the cover to the specified torque or the

filter element may break. Do not use an adjusta-

ble spanner or other open tool, as there is a risk

of damaging the filter cover.

9. Bleed the fuel system as per the following

section.

10. Start the engine and check that no leakage

occurs.

57

Fuel system

Bleeding the fuel system

Bleeding the fuel system using a suc-

tion tool

Tools

Designation

Illustration

Suction tool

Note:

Scania recommends bleeding the fuel system us-

ing suction tools rather than with a hand pump.

This is a quicker and simpler method, which en-

sures a complete bleeding.

Environment

Use a suitable container. The fuel collected must

be disposed of as specified in national and inter-

national laws and regulations.

1. Attach a clear plastic hose to the bleed nipple

on the fuel filter housing. Place the end of the

plastic hose in a container that holds at least

3 litres (1 US gallon).

58

Fuel system

2. Connect the suction tool.

3. Connect compressed air to the suction tool.

Turn the rotary control to create a vacuum.

4. Open the bleed nipple. Hold the suction tool

straight and draw out at least a full container

of fuel.

Once the fuel coming out of the hose is free

of air bubbles, then bleeding is complete.

5. Close the bleed nipple. Remove the hose and

suction tool.

6. Start the engine and check that no leakage

occurs.

59

Fuel system

Bleeding the fuel system using a

hand pump

1. Attach a clear plastic hose to the bleed nipple

on the fuel filter housing (1). Place the end of

the plastic hose in a container that holds at

2

least three litres (1 US gallon).

2. Open the bleed nipple and pump with the

hand pump (3) until fuel comes out of the

hose. If the fuel system is empty, it is neces-

sary to pump approximately 100 strokes in

order to draw up the fuel. Depending on the

1

installation, a significantly greater number of

pump strokes may be required before fuel

comes out.

3. Pump until fuel without air bubbles comes

out, approximately 20 strokes.

3

4. Close the bleed nipple and remove the hose.

5. Transfer the hose to the fuel manifold bleed

nipple (2).

1. Fuel filter housing bleed nipple.

6. Open the bleed nipple and pump using the

hand pump (3) until fuel without air bubbles

2. Fuel manifold bleed nipple.3. Hand pump.

appears, approximately 50 pump strokes.

7. Close the bleed nipple and remove the hose.

8. Pump approximately 20 strokes with the

hand pump until the overflow valve opens. A

hissing sound should be heard.

9. Start the engine. The engine should be easy

to start.

10. If the fuel filter has been renewed, check that

no fuel is leaking from the filter. If there is

leakage, tighten the filter more.

60

Other

Other

2

5

4

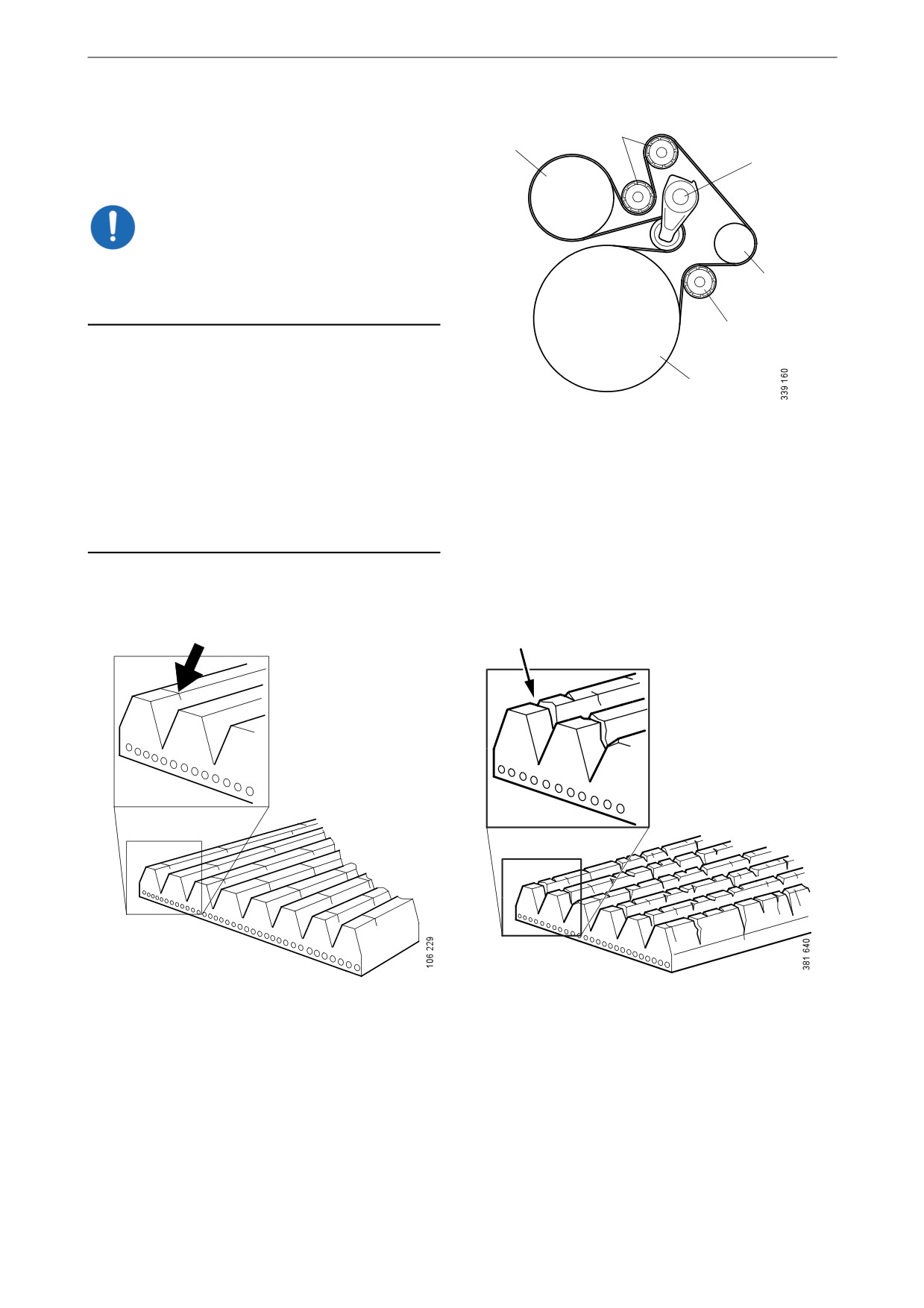

Checking the drive belt

IMPORTANT!

Before starting, make a note of how the drive belt

is fitted. Refit the drive belt with the same direc-

3

tion of rotation as it had before removal.

2

1. Check the drive belt for cracks. Renew the

drive belt if deep cracks have formed.

1

Note:

Example of a drive belt.

Small and shallow cracks are normal and form

1. Crankshaft

after only a few hours of operation. They do not

mean that the drive belt needs to be renewed. If

2. Idler roller

there are many deep cracks, or if parts of the

3. Alternator

drive belt have started to come off, the drive belt

must then be renewed.

4. Belt tensioner

5. Coolant pump

Example of a minor crack in the drive belt. The drive The drive belt has deep cracks and must be renewed.

belt can be refitted.

61

Other

2. Check drive belt wear. Renew the drive belt

if it is too worn.

The drive belt is starting to become worn, but can be

The belt is worn down to the cord. The drive belt

refitted.

must be renewed.

Checking for leaks

IMPORTANT!

If serious leakage occurs, contact your nearest

Scania workshop.

1. Start the engine.

2. Check for oil, coolant, fuel, air or exhaust

leaks.

3. Tighten or renew leaking connections.

Check the overflow holes which show

whether the O-rings between the cylinder

liners and crankcase are leaking.

4. Check whether the drain hole on the coolant

pump is blocked. If there is a leak, renew the

pump seal or the entire coolant pump.

62

Other

Checking and adjusting the

valve clearance and unit in-

jectors

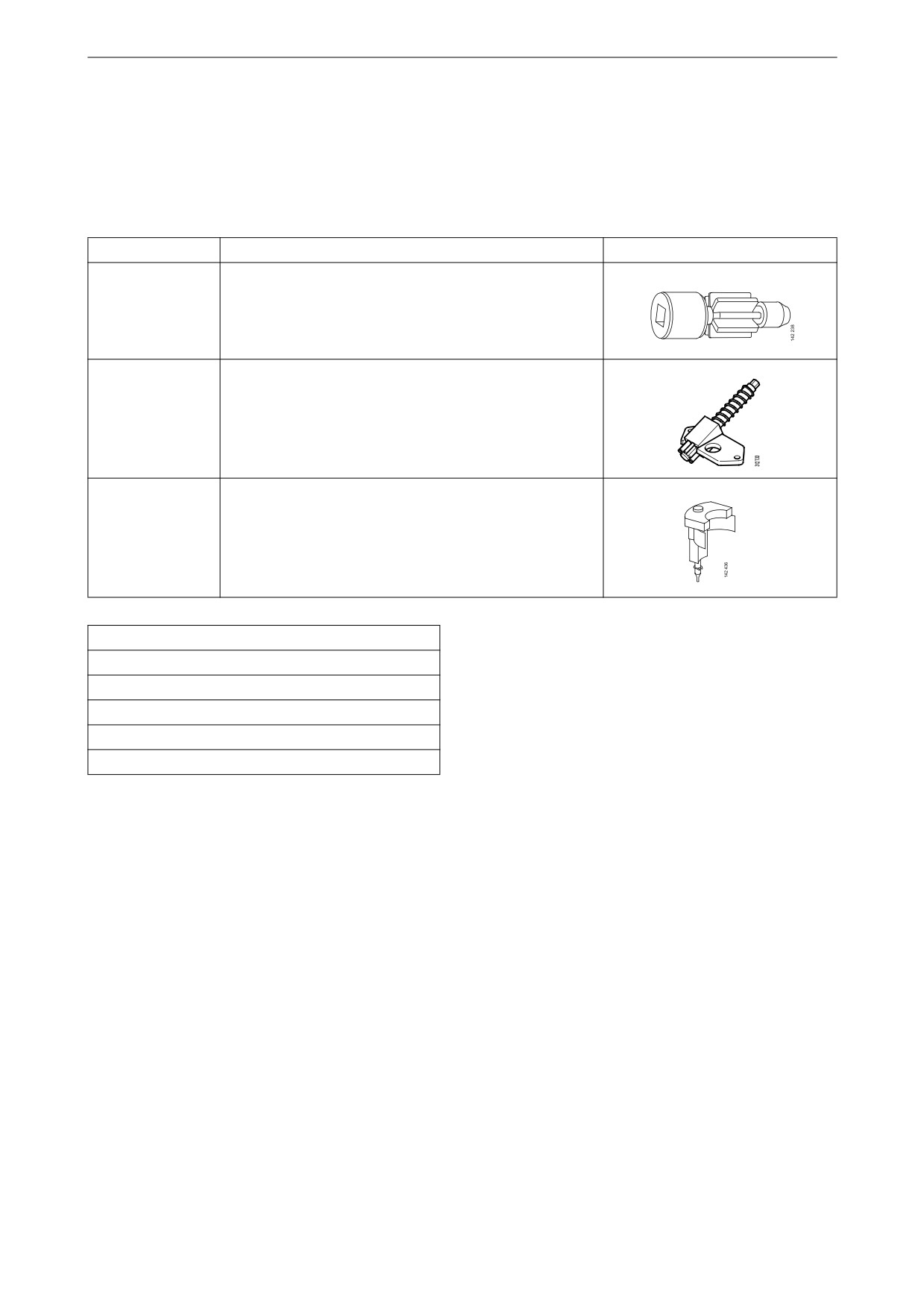

Special tool

Number

Designation

Illustration

99 309

Turning tool for rotating the flywheel from below

2 402 509

Turning tool for rotating the flywheel from above

99 442

Setting tool

Other tools

Torque wrench, 0-50 Nm

Waterproof felt-tip pen

0.45 and 0.70 mm feeler gauges

Flash light

Mirror

63