Scania DI9 55 - DI9 59. Marine engine. Operator’s manual - part 4

24. Daily:

CHECKING FOR LEAKAGE, RECTIFY

AS NECESSARY

- Start the engine.

- Check for oil, coolant, fuel, air and exhaust leakages.

- Tighten or change leaking connections. Check the overflow holes (1)

which show whether the O-rings between the cylinder liner and crank-

case are leaking, see drawing.

a) If coolant is leaking out, the two upper O-rings are leaking.

Ensure that any leakage does

b) If oil is leaking out, the lower O-ring is leaking.

not pollute the environment.

A small amount of leakage from the overflow holes during the engine

running-in period is normal. (Seals and O-rings are lubricated with soap

or oil when fitted).

This leakage normally stops after a time.

In case of major leakage,

contact the nearest Scania

workshop.

1

48

2001-05:1

25. Every 2400 hours:

CHECKING/ADJUSTING VALVE

Immobilise the starting device

CLEARANCE

when working on the engine.

Note Checking/adjusting valve clearance should also be done after the

If the engine starts out of

first 400 hours of operation.

control, there is a

Valves clearances should be adjusted when the engine is cold, at least 30

SERIOUS RISK

minutes after running.

OF INJURY.

Rocker cover gaskets should be changed as necessary. Tightening torque:

25 Nm.

Intake valve clearance: 0.45 mm

Outlet valve clearance: 0.80 mm.

1

Alternative 1

- Set No. 1 cylinder to TDC by turning the engine in its direction of rota-

2

tion until both valves are closed.

- Adjust the following valves. Correct valve clearance is indicated on the

3

instruction plate on one of the rocker covers:

Cylinder 1

Intake and exhaust

4

2

In

3

Ex

4

In

5

5

Ex

- Set No. 6 cylinder to TDC by turning the engine one revolution in its

6

direction of rotation.

FLYWHEEL

- Adjust the following valves:

Cylinder 2

Ex

3

In

4

Ex

TDC

TDC

5

In

No. 6 cyl

No. 1 cyl

6

In and ex

Note

Readings can either be taken

from underneath or from

above, depending on which

flywheel is used.

The cover not being used is

covered with a seal and an

instruction plate.

FLYWHEEL

Intake valve

Covers for reading

on flywheel casing

Exhaust valve

2001-05:1

49

Alternative 2

- Set the No. 1 cylinder to TDC by turning the engine in its direction of

rotation until both valves are closed.

- Adjust both the valves for the No.1 cylinder. Correct valve clearance is

indicated on the instruction plate on one of the rocker covers.

- Repeat this procedure with the remaining cylinders in the order

5 - 3 - 6 - 2 - 4 (firing sequence) by turning the engine 1/3 revolution in

its direction of rotation between each adjustment.

26. Every 2,400 hours:

CHANGING (or CLEANING) THE

CLOSED CRANKCASE VENTILATION

VALVE

Alternative 1:

Change the valve at the specified interval.

Alternative 2:

- Remove the valve after the specified interval.

- Clean the valve by placing it in a bath of diesel fuel oil overnight. Then

rinse it several times in diesel and allow it to drip dry.

- Refit the valve.

- The valve may be reused (cleaned), maximum twice after the initial

2400 hours of operation. Take care to mark the valve after cleaning it.

50

2001-05:1

LONG-TERM STORAGE

If the engine is not to be used for a lengthy period of time, special measures

should be taken to protect the cooling system, fuel system and combustion

chamber from corrosion and the exterior from rusting.

The engine can normally stand idle for up to six months. If it remains unused

for longer than this the following measures, which provide protection for

about four years, should be adopted. An alternative to preparing the engine

for long-term storage is to start the engine and warm it up every 6 months.

Preparing the engine for long-term storage means:

- Thoroughly cleaning the engine

- To run the engine for a period of time with preservative fuel,

preservative oil and preservative coolant.

- Otherwise preparing the engine for storage (filter changes, lubrication,

etc.).

Preservative coolant

Ethylene glycol, if swallowed

If the engine is to be stored with a full cooling system, use coolant containing

50% glycol by volume. Glycol without nitrite-based inhibitor must be used.

can be fatal.

E.g. BASF G48 or BASF D542.

Avoid contact with the skin.

Preservative fuel

- Use diesel fuel mixed with Lubrizol 560A or equal.

- Mix 1 cm3 (ml) of Lubrizol 560A with 10 dm3 (l) of fuel.

!

HANDLING LUBRIZOL 560A

Hazardous!

Contains aromatic hydrocarbons

Use spot extractors where there is a danger of vapour build-up.

Wear protective gloves and goggles when handling Lubrizol. Do not use contaminated clothing.

In case of splashes in the eye: Rinse with moderate water spray (for min. 15 minutes). Seek medical attention.

In case of skin contact:

Wash affected areas with soap and water.

If you inhale it:

Fresh air, rest and warmth

Flammable:

Fire class 2A. Flash point + 27°.

In case of fire: Extinguish using carbonic acid, powder or foam

Storage:

In properly sealed container in a dry, cool place. Keep out of reach of children.

2001-05:1

51

Preservative oil

Suitable preservative oil can be supplied by most petroleum companies.

For example: Dinitrol 40 or the equivalent.

Preparations for storage

-

Drain and flush the cooling system. Top up with preservative coolant.

-

Warm up the engine on regular fuel. Stop the engine and drain the oil.

Always use suitable containers

-

Change the fuel filter and turbo filter.

to avoid spillage when

-

Fill the engine with preservative oil up to the minimum level on the

draining oil and coolant.

dipstick.

Dispose of used oil and coolant

-

Mix preservative fuel in a can. Detach the fuel pipe at the feed pump

through an authorized waste

suction line and connect a hose from the can.

disposal contractor.

-

Detach the fuel pipe at the overflow valve and connect a return hose to

the can.

-

Start the engine and run it at about 1000 rpm (not single-speed engines)

for 20-25 minutes.

-

Stop the engine, remove the hoses and connect the regular fuel lines.

-

Oil the valve mechanism generously with preservative oil.

-

Remove the injectors and spray preservative oil into each cylinder,

max 30 cm3 (ml).

Turn the engine over a few times using the starter motor. Spray a small

amount of oil additionally into each cylinder.

After this the engine must not be cranked. Refit the injectors.

-

Drain the preservative oil from the engine. Fresh engine oil can be filled

directly or when the engine is taken out of storage.

-

Drain the coolant if the engine is not to be stored with a full cooling

system. Plug and tape over all coolant connections (if the cooling system

is not completely assembled).

-

Air cleaner: Clean or change the filter element.

-

Cover air intakes and exhaust pipes.

-

Alternator and starter motor:

-

Spray with water-repellent anti-corrosive oil, CRC 226, LPS1 or the

equivalent.

-

Spray the outside of bright engine parts, first with penetrating preserva-

tive oil such as Dinitrol 25B and then with Dinitrol 112 or the equiva-

lent.

Winter storage

- In order to minmize the risk of condensation water in the fuel tank

during a winter stop, it should be filled with fuel.

52

2001-05:1

- Attach a label to the engine showing the date of preservation and

clearly stating that it must not be started or cranked.

STORED ENGINE

Date

Do not start or crank!

Batteries

Remove the batteries for trickle charging at a charging station. (This does not

apply to batteries which, according to the manufacturer, are maintenance

free.) The same is applicable for short-term storage if the engine has not been

Wear gloves and eye protection

prepared for storage as above.

when charging and handling

batteries.

Storage

Batteries contain a highly

After the preparations, the engine should be stored in a dry and warm place

corrosive acid.

(room temperature).

Taking out of storage

(Procedure when the engine is to be put into operation)

- Remove plugs and tape from coolant connections, air intakes and

exhaust pipes.

- Fill the system with coolant, see page 18.

- Check the oil level in the engine or top up with new motor oil.

Always use suitable containers

to avoid spillage when

- Turn the engine over a few times with the injectors removed, at the same

time copiously oiling the valve mechanism with pushrods and tappets.

draining oil and coolant.

Dispose of used oil and coolant

Important The engine must be cranked with the injectors removed so that

through an authorized waste

surplus preservative oil will be pressed out of the cylinders.

disposal contractor.

- Fit the injectors.

- Empty the fuel system main filter of preservative oil.

- Bleed the fuel system.

- Wash off any externally applied preservative oil, using white spirit.

2001-05:1

53

TECHNICAL DATA

GENERAL

DI9

Number of cylinders

6 in line

Cylinder bore

mm

115

Stroke

mm

144

Displacement

dm3 (litres)

9.0

Number of main bearings

7

Firing sequence

1 - 5 - 3 - 6 - 2 - 4

Compression ratio

15:1

Engine direction of rotation viewed from rear

Anti-clockwise

Fan direction of rotation viewed from the front

Clockwise

Cooling

Fluid

Valve clearance, cold engine

intake valve

mm

0.45

exhaust valve

mm

0.80

Weight (without coolant and oil)

engine with heat exchanger

kg

905

Output

see “Engine record card”

LUBRICATION SYSTEM

Max. oil pressure

(warm engine at speeds above 800 rpm) bar (kp/cm2)

6

Normal oil pressure

(warm engine at operating speed)

bar (kp/cm2)

3 - 6

Min. oil pressure

(warm engine 800 rpm)

bar (kp/cm2)

0.7

Oil capacity, see page 27

Crankcase pressure with closed crankcase

ventilation

mm VP

-55 - +20

54

2001-05:1

FUEL SYSTEM

DI9

Pump setting BTDC

See plate on rocker cover

Injectors, opening pressure

bar (kp/cm2)

300

Low idle

with RSV governor

rpm

700

Maximum full load speed

See engine card

Fuel

Diesel fuel oil1

Tightening torques:

Socket nut for injectors

Nm

70

Cap nut for delivery pipe

Nm

20

Oil leakage connection

Nm

11

1 see page 56

COOLING SYSTEM

Number of thermostats

2

Thermostat, opening temperature

°C

79

Coolant temperature:

system with atmospheric pressure

°C

70 - 93

system with positive pressure

°C

70 - about 100

Capacity with heat exchanger

dm3 (litre)

40

ELECTRICAL SYSTEM

System voltage

V

24

Alternator, current

A

65 or 90

Starter motor power

kW (hp)

4.0

(5.4)

Monitors, settings:

Oil pressure monitor

bar (kp/cm2)

2-pole: 0.7 ± 0.15

Temperature monitor

°C

Stamped on monitor hexagon

2001-05:1

55

FUEL

Diesel fuel

The composition of the diesel fuel is vitally important to the operation and

life of the engine and the fuel injection pump. The engine power output and

the exhaust emissions are also dependent on the fuel quality.

The requirements and the test standards for the most important properties are

described in the workshop manual in sections that can be ordered from your

Scania dealer or directly from Scania. The address of Scania is printed on the

cover.

The diesel fuel shall comply with the following standard:

EN 590 (European standard).

The table below shows the requirements for some of the most important

properties:

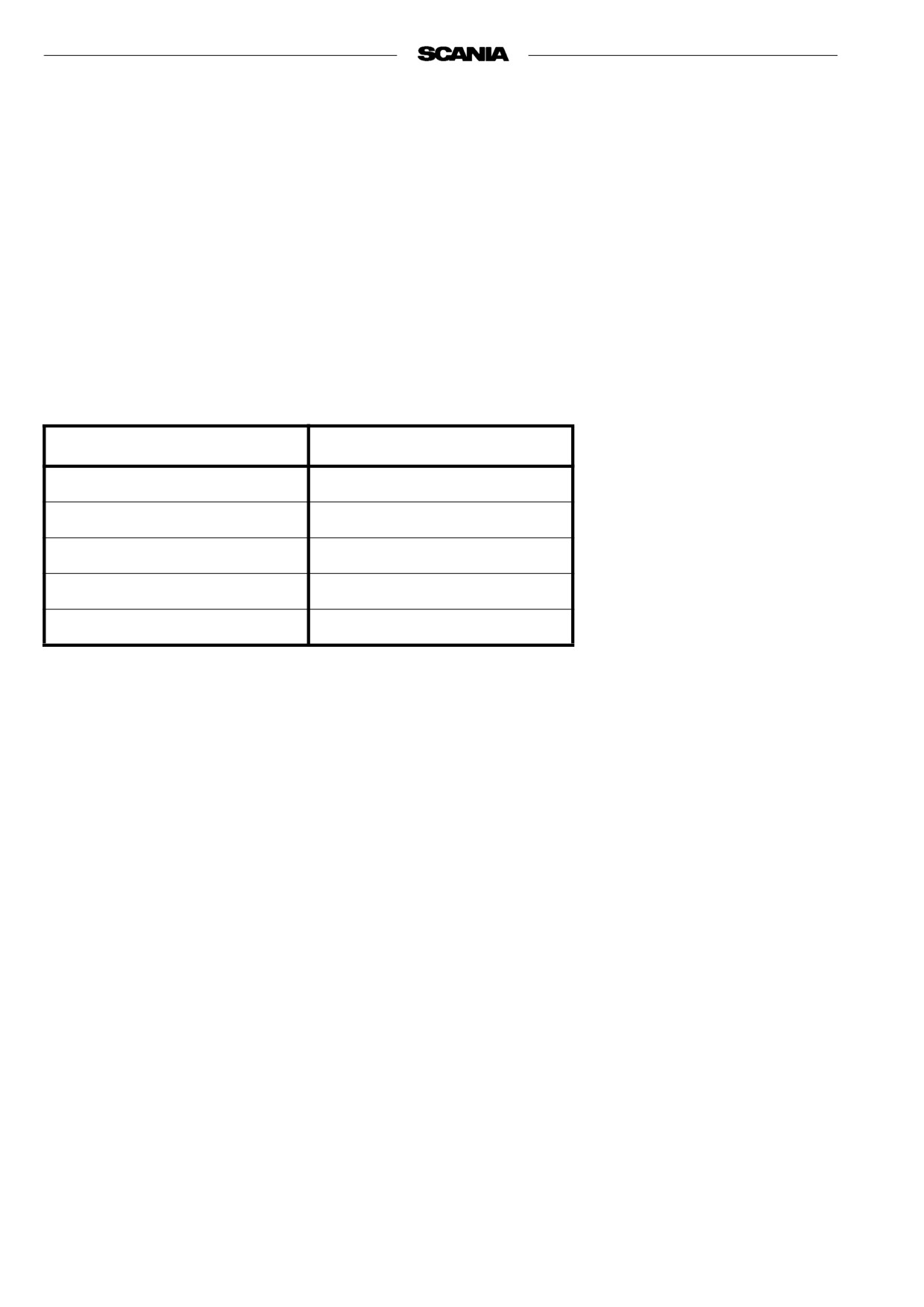

Property

Requirement

Viscosity at 40°C

2.0 - 4.5 mm2/s (cSt)

Density at 15°C

0.82 - 0.86 kg/dm3

Sulphur (concentration by mass)

max. 0.3%

Ignitability (CET rating)

min. 49

Flashpoint

56°C

Environmentally favourable fuels (low sulphur fuels)

There are three different grades of so called environmentally favorable fuels

(SS15 54 35). Grade 1 is sulphur-free and grade 2 is low in sulphur.

Compared with class 3 (normal fuel), these fuels are less dense and this

reduces engine power output. Only class 1 fuel should be used with a

catalytic converter.

Short term use of fuel with a higher sulphur content than 0.05% by weight

will not cause permanent damage to the catalytic converter.

The catalytic converter may, however, require fuel with low sulphur content

for some time after this to regain its normal efficiency.

56

2001-05:1

Temperature dependence of diesel fuel

At temperatures lower than those specified for the diesel fuel, paraffin wax

may precipitate from the fuel and block filters and pipes. The engine can then

loose power or stop.

The diesel fuel is adapted for use in the specific climate of each country.

It is not permitted to mix

If a vehicle or an engine is to be operated in a temperature zone with lower

kerosene with diesel fuel that is

temperature than normal, first identify the temperature properties of the

already adapted for the climate

fuel concerned.

concerned. The injection pump

The properties of the fuel when cold can be improved by adopting one of the

may be damaged. All use of

following measures before the temperature drops:

paraffin other than kerosene is

- If the fuel concerned is not intended for the expected temperature and no

forbidden, as it causes

diesel fuel with the correct temperature properties is available, we

engine damage.

recommend that an electric fuel heater be installed as a preventative

measure.

- The low temperature properties of diesel fuel may be improved by

adding kerosene as a preventative measure. A maximum of 20% may

be added. When refuelling, the kerosene should be added first, so that it

mixes thoroughly with the diesel fuel.

It is not permissible to mix

Note: It is prohibited to use kerosene in engine fuel in some countries.

petrol with diesel fuel. Petrol

- To prevent water in the fuel from freezing and forming ice, maximum

may cause wear to the fuel

0.5-2% alcohol (isopropanol) may be added.

injection pump and it may also

Drain fuel tanks and drain or renew fuel filters at regular intervals.

cause damage to the engine.

2001-05:1

57

ALPHABETIC INDEX

Air cleaner

38

Leakage

48

Air cleaner, filter element

38

LED functions

14

Air cleaner, low pressure indicator

38

Long-term storage

51

Air cleaner, pre-filter

38

Low pressure indicator

38

Air cleaner, safety cartridge

40

Lubricating oil pressure

22

Lubricating oil pressure monitor

46

Batteries

43

Lubricating oil system

26

Battery, changing

47

Maintenance

24

Certified engines

5

Maintenance Schedule

25

Checks after running

23

Checks before running

19

Oil analysis

26

Clutch

23

Oil capacity

27

Coolant

32

Oil change

27

Coolant level

30

Oil cleaner

28

Coolant level monitor

44

Oil grade

26

Coolant temperature

21

Oil level

27

Coolant temperature monitor

45

Oil pressure

22

Coolant, changing

34

Oil pressure monitor

46

Cooling system

30

Oil pressure monitor, DEC2

46

Cooling system, cleaning

35

Corrosion inhibitor

34

Pre-filter, air cleaner

38

DEC2 Control system

12

Running

21

DEC2 sensors

13

Drive belt

47

Safety cartridge, air cleaner

40

Safety details

6

Electrical system

43

Safety precautions for care and maintenance . . 8

Engine speed

21

Safety precautions for handling materials

8

Environmental responsibility

4

Safety precautions for operation

7

Starting the engine

19

Fault codes DEC2

16

Start-up report

1

Filter, air cleaner

38

Stopping the engine

22

Filter, fuel

41

Storage

53

Foreword

2

Fuel filter, changing

41

Taking out of storage

53

Fuel level

41

Technical data

54

Fuel specifications

56

Temperature monitor

45

Fuel system

41

Turbo filter

30

Fuel system, bleeding

41

Type designations

10

Glycol

32

Valve clearance

49

Venting, fuel system

41

Injectors

42

Warranty

1

58

2001-05:1