Scania DC9 EMS with S6/PDE. Industrial engine. Operator’s manual - part 4

49

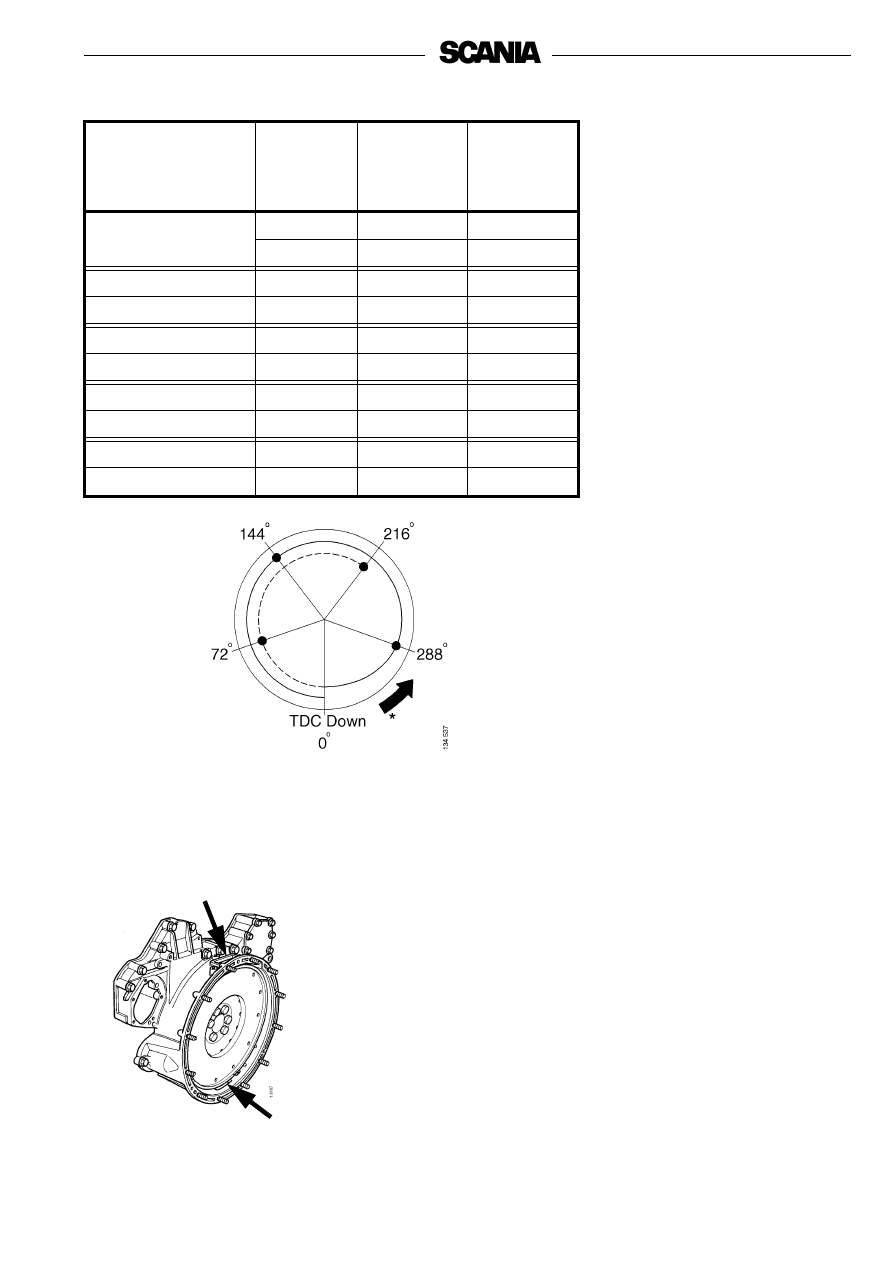

Mark on flywheel

(reading taken

through the lower

opening)

Revolution

Valve

overlap on

cylinder

Adjust the

valves on

cylinder

TDC Down (0°)

1

-

1

2

1

-

144°

1

-

2

504°

2

2

-

288°

1

-

4

648°

2

4

-

72°

1

5

-

432°

2

-

5

216°

1

3

-

576°

2

-

3

Flywheel seen from the rear of the engine.

*Direction of rotation when adjusting.

The solid line shows the order for angles on the first rotation and the

broken line the order for rotation 2.

Note:

Readings can be taken from the

flywheel through covers in the

flywheel housing either from

above or underneath depending

on access when fitting.

It says "up" or "down" on the

flywheel.

Both openings are fitted with a

cover at delivery.

Openings for taking readings

on the flywheel housing