Scania DC9 EMS with S6/PDE. Industrial engine. Operator’s manual - part 3

33

- Wash all parts in diesel oil.

- Make sure the nozzles on the rotor are not blocked or damaged.

- Check that the bearings are undamaged. If they are damaged the entire

rotor must be renewed.

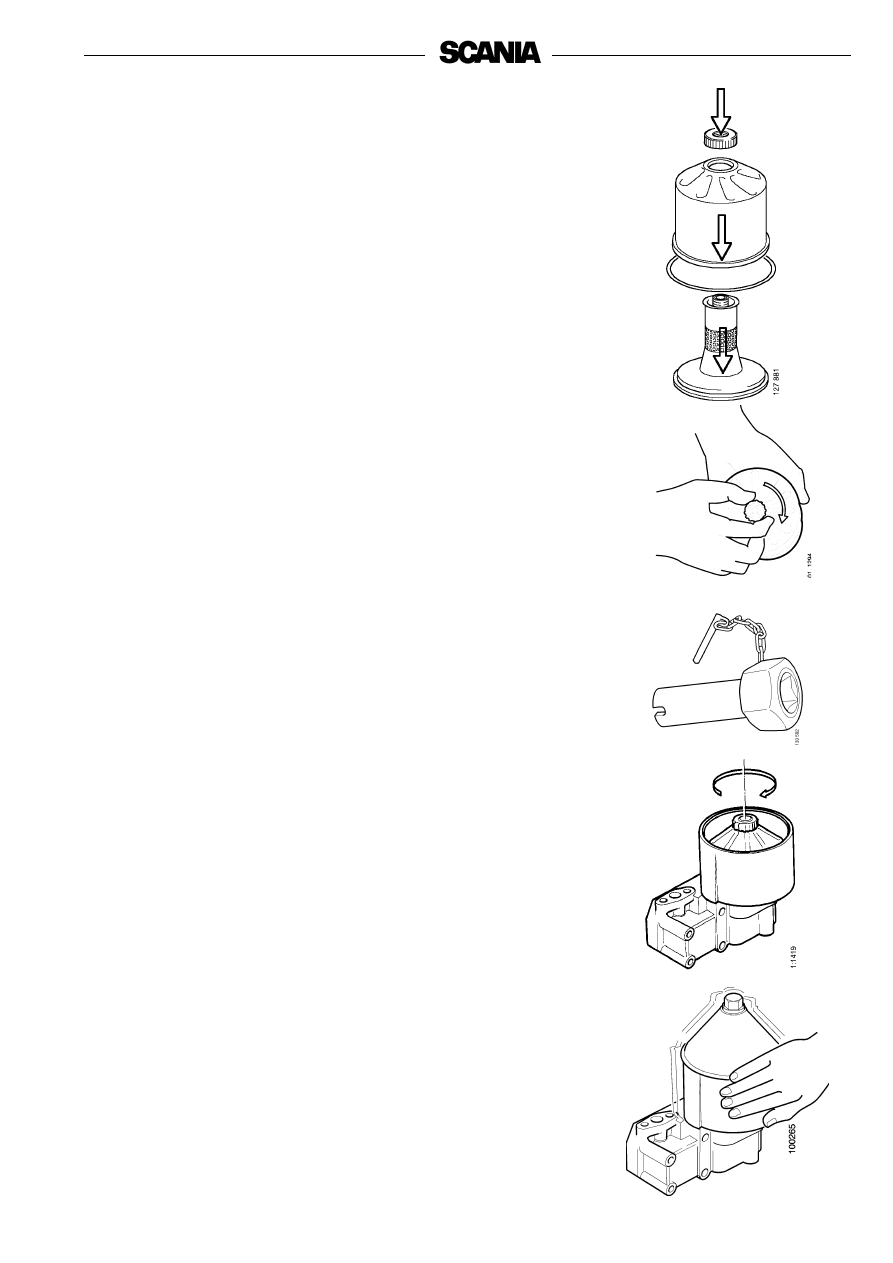

- Fit a new O-ring on the rotor and fit the strainer.

- Reassemble the rotor.

- Tighten the rotor nut firmly by hand.

- Check that the shaft is not loose. If it is loose, use locking compound

561 200 and torque tighten the shaft to 34 Nm using tool 98 421.

- In order to tighten the rotor shaft, it is necessary to modify socket

wrench 98 421:

- Drill out the threads from a M20 nut so that it fits on the square drive

of the socket wrench.

- Weld the nut into place.

- Refit the rotor.

- Check that it rotates easily by rotating it manually.

- Fit a new O-ring on the cover and fit the cover.

- Screw the bowl on and tighten the lock nut to 15 Nm.

Tighten the nut carefully so as not to damage the rotor shaft, nut or cover.

Functional inspection

The rotor rotates very fast and should continue to rotate when the engine has

stopped.

- Stop the engine when it is warm.

- Listen for a whirring sound from the rotor or feel whether the cleaner

housing is vibrating.

The rotor normally continues spinning for 30-60 seconds after the engine has

stopped.

If not: dismantle and check.