SCANIA INDUSTRIAL ENGINES (specification) - part 22

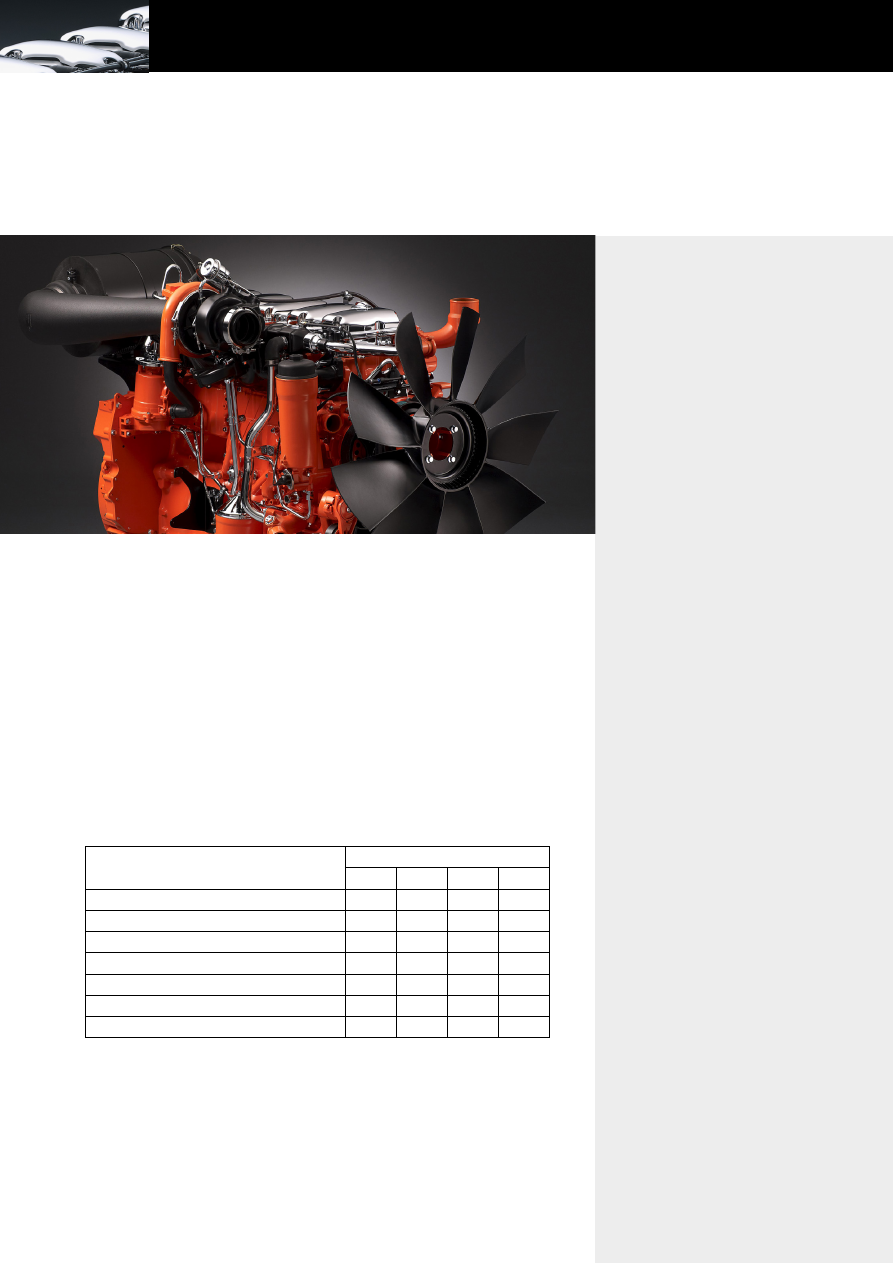

SCANIA INDUSTRIAL ENGINES

DC09 074A. 276 kW (375 hp)

EU Stage II, China Phase II and Russia Stage I

Standard equipment

• Scania Engine Management System, EMS

• Unit injectors, PDE

• Turbocharger

• Saver ring in cylinder liner

• Fuel filter and extra pre-filter

with water separator

• Oil filter, full flow

• Centrifugal oil cleaner

• Oil cooler, integrated in cylinder block

• Oil filler, in valve cover

• Deep front oil sump

• Oil dipstick, in cylinder block

• Magnetic drain plug for oil draining

• Starter motor, 1-pole 6.0 kW

• Alternator, 1-pole 100 A

• Flywheel, for use with friction clutch

• Silumin flywheel housing, SAE 1 flange

• Front mounted engine suspension

• Open crankcase ventilation

Optional equipment

• Cooling package

• Puller and pusher fans

• Fan ring with sealing

• Hydraulic pump

• Air compressor

• AC compressor

• Side-mounted PTO

• Front-mounted PTO

• Exhaust connections

• Engine heater

• Flywheels SAE11.5”, SAE14”, DANA15/16”,

DANA17” flexplate, ZF WG260

• Stiff rubber engine suspension

• Air cleaner

• Closed crankcase ventilation

• Studs in flywheel housing

• External thermostat for extra oil cooler

• Coolant level sensor

• Oil level sensor

• Low oil sump

The industrial engines from Scania are based on a robust design with a strength

optimised cylinder block containing wet cylinder liners that can easily be exchanged.

Individual cylinder heads with 4 valves per cylinder promotes reparability and fuel

economy.

The engine is equipped with a Scania developed Engine Management System, EMS,

in order to ensure the control of all aspects related to engine performance.

The injection system is based on electronically controlled unit injectors that give low

exhaust emissions with good fuel economy and a high torque. The engine can be fit-

ted with many accessories such as air cleaners, PTOs and flywheels in order to suit a

variety of installations.

This specification may be revised without notice.

Engine speed (rpm)

1200

1500

1800

2100

Gross power (kW)

230

276

276

276

Gross power (hp)

313

375

375

375

Gross torque (Nm)

1830

1757

1464

1255

Spec fuel consumption. Full load (g/kWh)

199

204

206

221

Spec fuel consumption. 3/4 load (g/kWh)

197

195

206

225

Spec fuel consumption. 1/2 load (g/kWh)

195

199

211

239

Heat rejection to coolant (kW)

94

101

101

112

Rating: IFN – Intermittent service: Rated output available 1/6 h.

Unlimited h/year service time at a load factor of 80%