содержание .. 27 28 29 30 ..

Scania 16 litre engine. Work Description - part 29

0120w13b.mkr

©

113

1

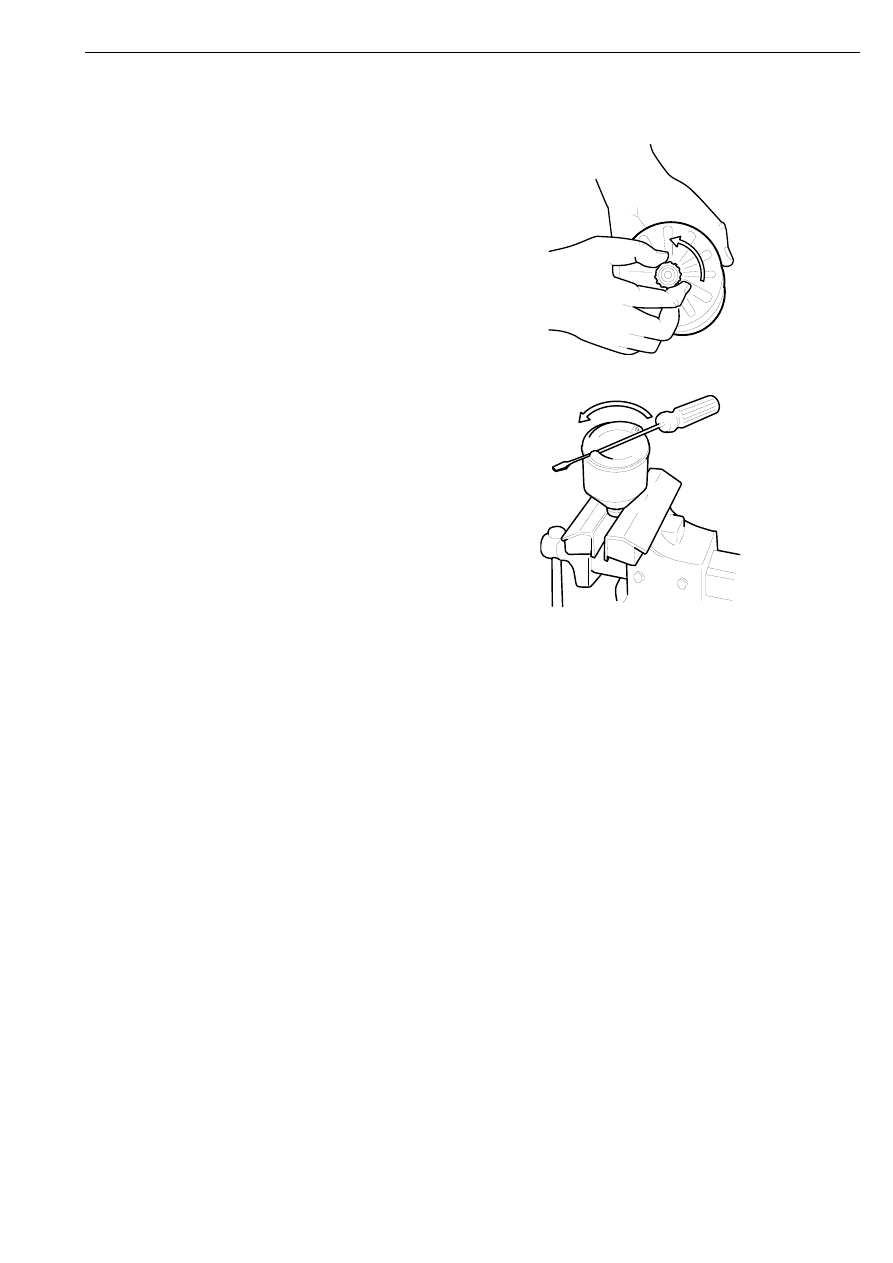

Unscrew the nut securing the outer lid.

2

Lift out the rotor. Wipe off the outside.

Undo the rotor nut and screw it about three

turns to protect the bearing.

0

11

2

86

x3

3

If the rotor nut is difficult to get loose, turn

the rotor upside down and fasten the rotor

nut in a vice. Turn the rotor

counterclockwise three turns by hand or if

this does not help, place a screwdriver

between the outlet holes.

x3

0

11

2

8

7

Oil cleaner

IMPORTANT! The rotor must not be put in a

vice. Never strike the rotor bowl. This may

cause damage resulting in imbalance.