содержание .. 16 17 18 19 ..

Scania 16 litre engine. Work Description - part 18

0110w14b.mkr

©

69

5

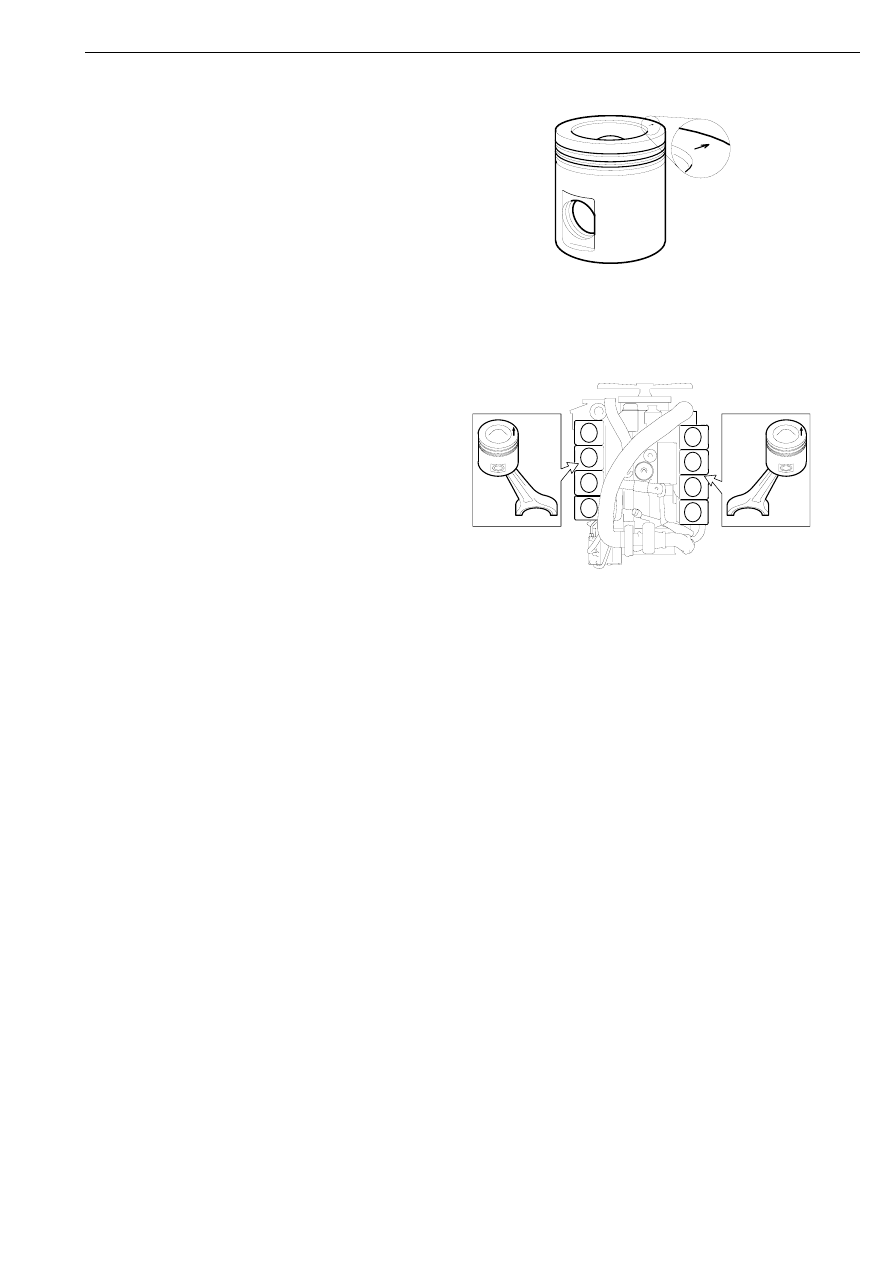

Fit the connecting rod and piston. The arrow

on the piston must be facing the front of the

engine. Applies to aluminium pistons only,

steel pistons are symmetrical. Clamp the

piston ring compressor 98 212 and push the

piston into the cylinder.

The arrow must be facing the front of the engine

116 033

116 085

6

Fit the connecting rod bearing shell into the

cap and lubricate the bearing surface. Fit the

cap. Lubricate the bolts, fit them and torque

tighten to 50 Nm+90°.

7

Fit the piston cooling nozzle. Tightening

torque 23Nm.

IMPORTANT! The piston cooling nozzle must

not be damaged. The oil jet must hit the piston

precisely. If it does not, the piston will become

too warm and result in engine breakdown.

Damaged nozzles must not be re-aligned, renew

them instead.

8

Fit the oil sump. Torque tighten the bolts to

32 Nm.

9

Fit the cylinder head. Tighten the cylinder

head bolts as described in Cylinder head,

fitting.

Piston and connecting rod