содержание .. 13 14 15 16 ..

Scania 16 litre engine. Work Description - part 15

0105w15b.mkr

©

57

Fitting

Tightening torques

Description

1

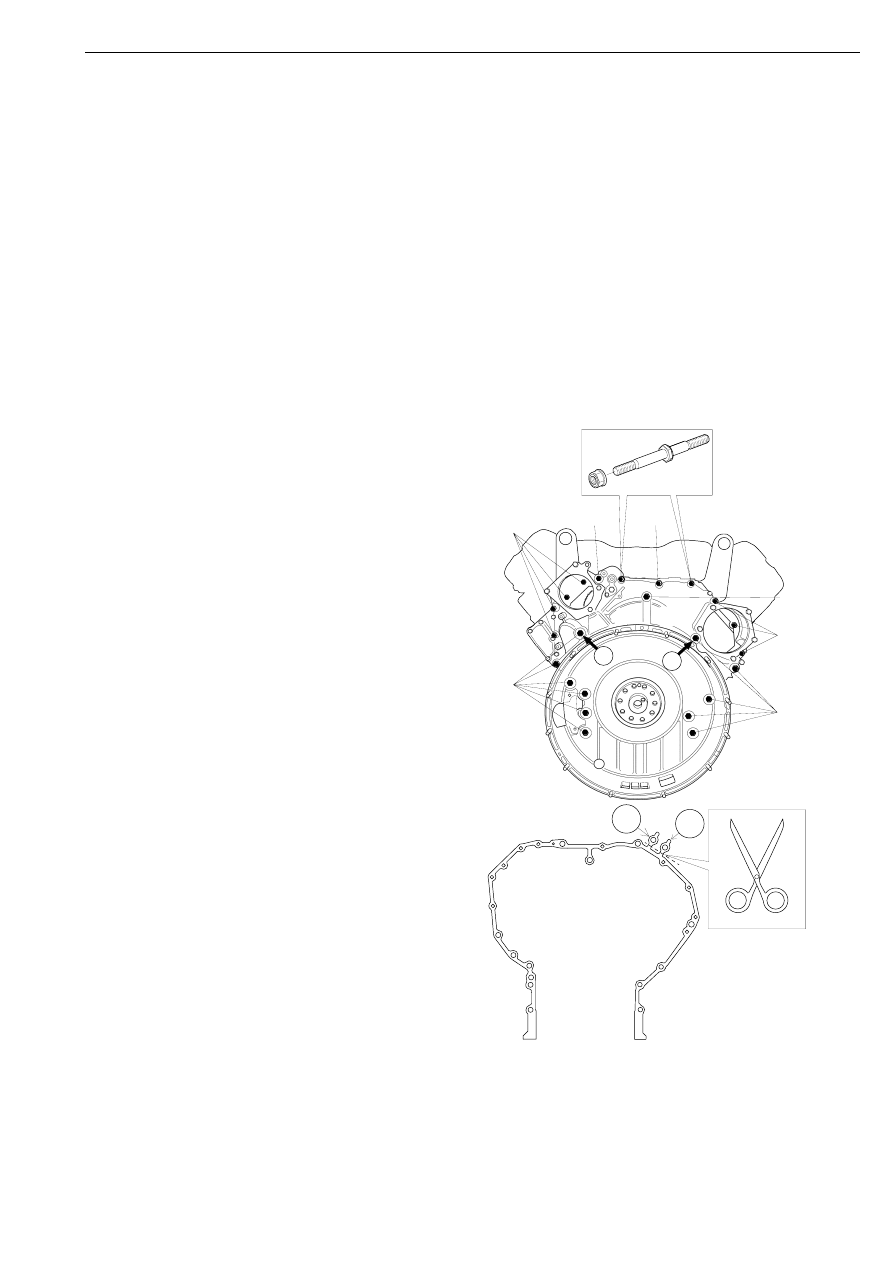

Clean the sealing surfaces. Carefully

remove any remains of the old gasket.

2

Fit the flywheel housing with a new gasket.

The two appendages, A and B, are to be

removed and used for bolts A and B.

3

Fit the bolts. Torque tighten the M12 bolts

and studs to 92 Nm and the M10 bolts to

50 Nm.

Bolts for flywheel housing

Flange bolt and stud,

M12 : 92 Nm

Flange bolt, M10 : 50 Nm

Nut for turbocharger manifold

92 Nm

Bolts for oil sump

32 Nm

Plug for oil sump

80 Nm

112 295

M12

M10

M12

M12

M10

M10

A

B

A

B

M10

M12

Flywheel housing