содержание .. 12 13 14 15 ..

Scania 16 litre engine. Work Description - part 14

0105w15b.mkr

©

53

Measuring the cylinder liner height

Specifications

Special tools

1

Thoroughly clean the cylinder block liner

shelf, the face around the cylinder, the

cylinder liner shelf and the upper face of the

cylinder liner.

2

Fit the cylinder liner without O-rings and

twist down by hand into position.

3

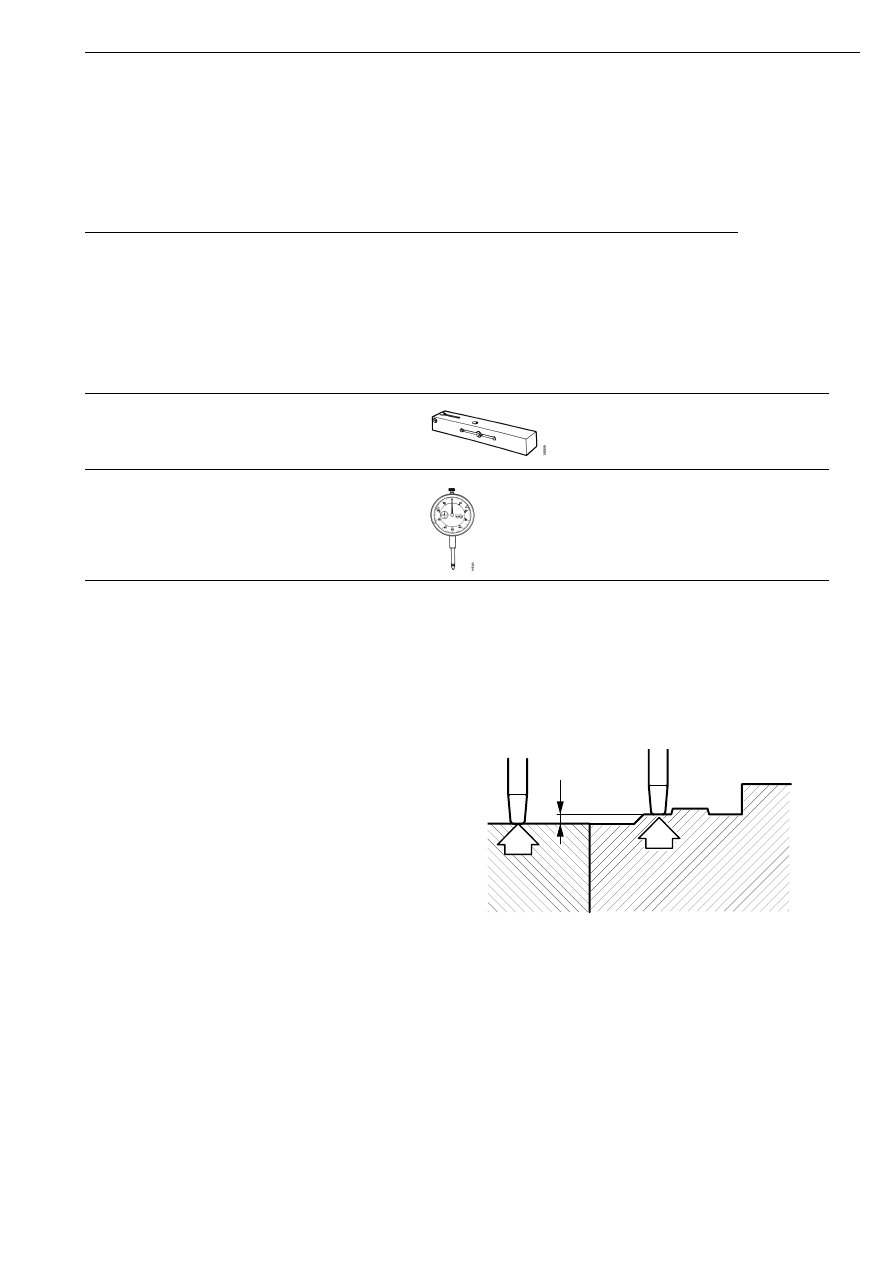

Place straight edge 87 198 with dial gauge

98 075 on the liner and zero the dial gauge

to the liner (A). Slide the tip of the dial

gauge over to the cylinder block (B) and

measure the height of the liner (A-B) as

illustrated. Measure each liner at two

diametrically opposite points.

Cylinder liner height above cylinder block

0.20 - 0.30 mm

Max. permitted difference in height between two diametrically

opposite points of a cylinder liner

0.02 mm

Number

Designation

Illustration

Tool board

87 198

Straight edge

D2

98 075

Dial gauge

D2

A Measured surface on cylinder liner

B Measured surface on cylinder block

C Tip of dial gauge

D Height of cylinder liner D = A-B

A

B

C

D

C

1

000

24

Cylinder liner