содержание .. 10 11 12 13 ..

Scania 16 litre engine. Work Description - part 12

0101w14b.mkr

©

45

5

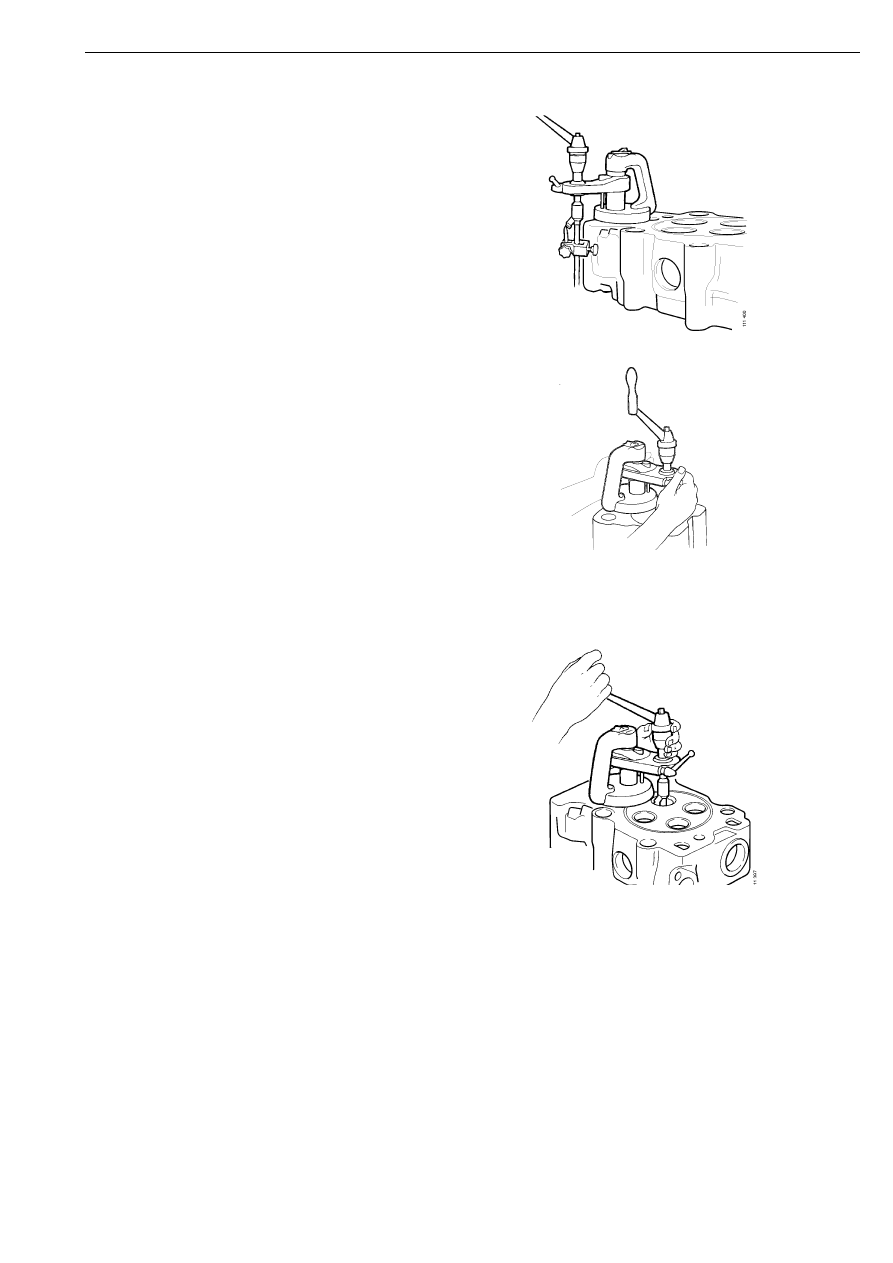

Set up the dial on the cutter adjuster using a

valve.

6

Adjust the cutter. Diameter 37.9 mm and

39.8 mm respectively, refer to Valve seat

insert, machining measurement.

7

Turn off the magnet (position 2). Insert the

guide spindle into the valve bushing. Adjust

the pivot plate so that the distance between

the cutter and the valve seat is

approximately 1 mm. Centre the tool

precisely.

01_1233

8

Turn on the magnet (position 1).

9

Apply the quick-action lock. Make sure the

crank can be turned easily. If not, redo the

centering.

10 Machine the valve seat by cranking

clockwise while turning the feed screw.

Never crank counterclockwise as this will

damage the cutter. Lubricate with cutting oil

while machining.

11 When the surface of the valve seat has been

machined, reduce the cutting pressure by

turning 2-3 revolutions without any feed.

Continue turning while backing the feed

screw. The valve seat cutter is now ready for

the next valve seat.

The valve seats can also be machined using tool

587 061.

Cylinder head