Peugeot 5008 (2017 year). Instruction - part 17

7

255

Practical information

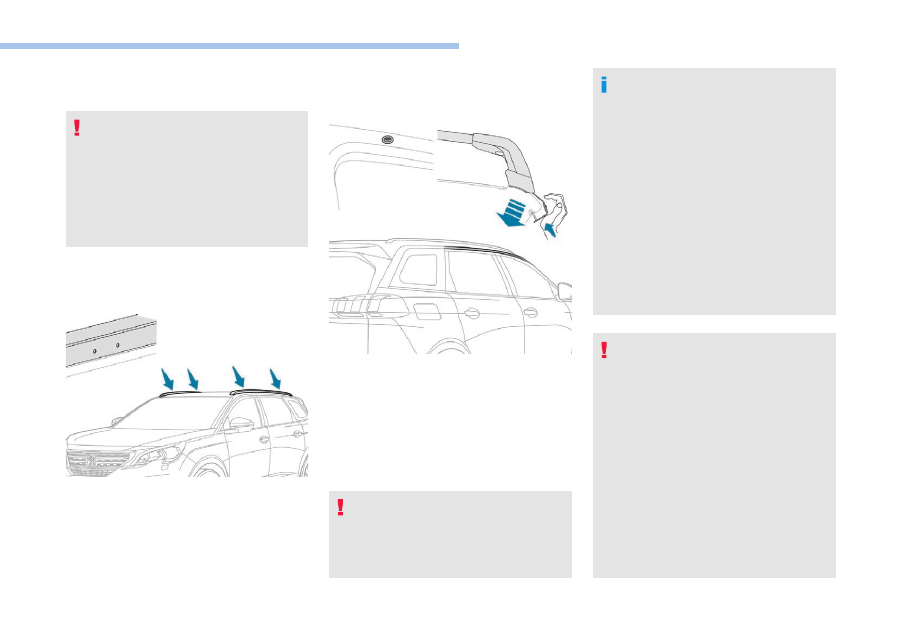

Fitting roof bars

As a safety measure and to avoid

damaging the roof, it is essential to use

the transverse bars approved for your

vehicle.

Observe the instructions on fitting and use

contained in the guide supplied with the

roof bars.

Fitting on longitudinal bars

Fitting directly to the roof

Sunroof

Check that the load does not pass below

the roof bars so that it does not impede

the movements of the sunroof.

The transverse bars must be fixed at the

engraved markings on the longitudinal bars.

You must only attach the transverse bars to

the four fixing points located in the roof frame.

These points are concealed by the vehicle

doors when the doors are closed.

You must attach the transverse bars only at the

four anchorage points located at the edge of

the roof.

Recommendations

Distribute the load uniformly, taking care

to avoid overloading one of the sides.

Arrange the heaviest part of the load as

close as possible to the roof.

Lash the load securely.

Drive gently: the vehicle will be more

susceptible to the effects of side winds

and the stability of the vehicle may be

affected.

On a long journey, check the security of

the load at every stop.

Remove the roof bars once they are no

longer needed.

Maximum load distributed across the

transverse roof bars, for a load height

not exceeding 40 cm (except bicycle

carrier): 80 kg.

For more information, contact a

PEUGEOT dealer or a qualified workshop.

If the height exceeds 40 cm, adapt the

speed of the vehicle to the profile of the

road to avoid damaging the roof bars and

the vehicle's anchorage points.

For transporting objects which are longer

than the vehicle, refer to local legislation.