Nissan Note E12. Manual - part 628

TM-70

< SYSTEM DESCRIPTION >

[CVT: RE0F11A]

STRUCTURE AND OPERATION

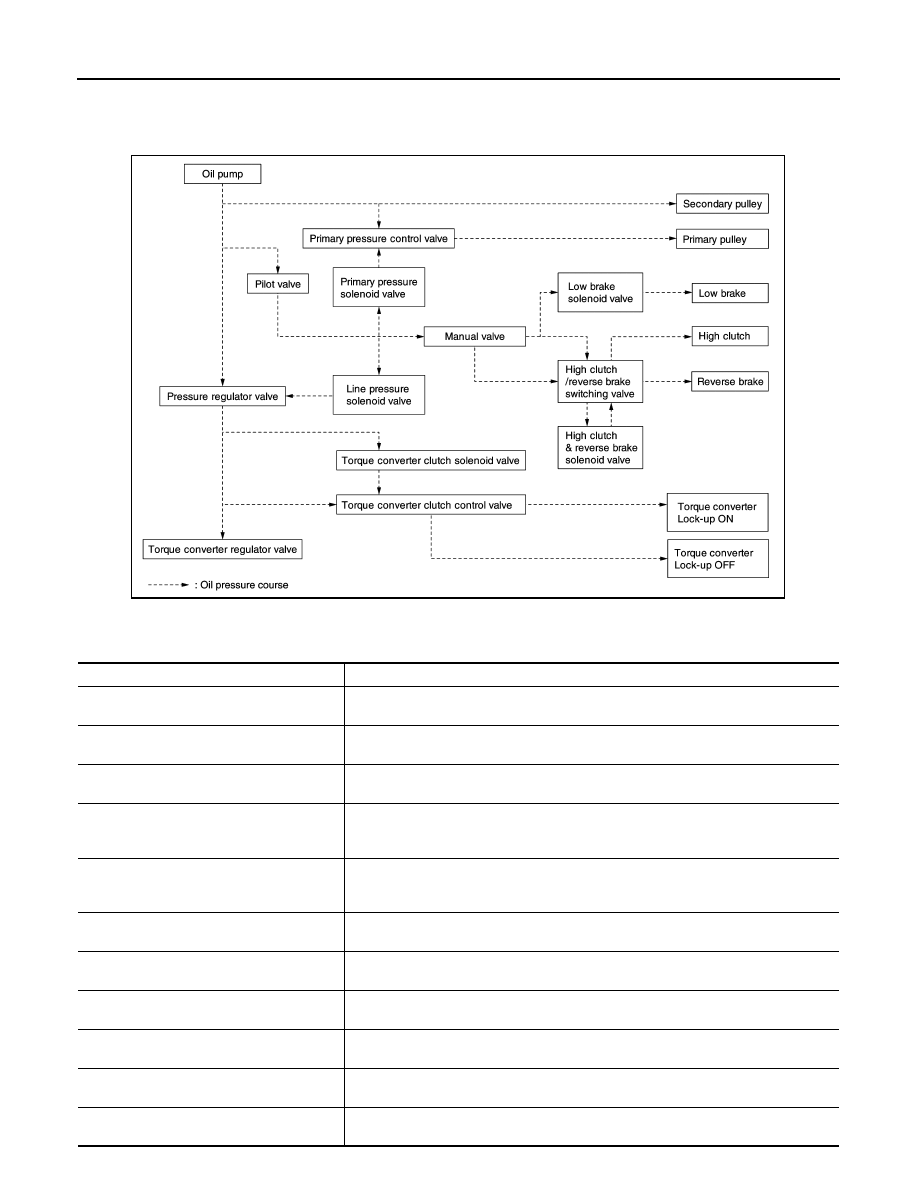

TRANSAXLE : Oil Pressure System

INFOID:0000000009019856

Oil pressure required for operation of the transaxle transmission mechanism is generated by oil pump, oil

pressure control valve, solenoid valve, etc.

TRANSAXLE : Component Description

INFOID:0000000009019857

JSDIA1826GB

Part name

Function

Torque converter

It is composed of the cover converter, turbine assembly, stator, pump impeller assem-

bly, etc. It increases the engine torque and transmits the power to the transaxle.

Oil pump

Through the oil pump drive chain, it uses the vane oil pump driven by the engine. It gen-

erates necessary oil pressure to circulate fluid and to operate the clutch and brake.

Counter gear set

The power from the torque converter is transmitted to the primary pulley through the

counter drive gear and the counter driven gear.

Belt & pulley (Continuously variable transmis-

sion)

It is composed of the primary pulley, secondary pulley, steel belt, etc. and the mecha-

nism performs shifting, changes the gear ratio and transmits the power with oil pressure

from the control valve.

Auxiliary gearbox (stepped transmission)

It is composed of the planetary gear, multi-disc clutch, multi-disc brake, etc. and the

mechanism performs shifting (1-2 gear shifting and reverse) with oil pressure from the

control valve.

Reduction gear set

Conveys power from the transmission mechanism to the reduction gear and the final

gear.

Parking mechanism

When the shift lever is changed to P position, the mechanism fixes the parking gear (in-

tegrated with the reduction gear) and the fixes the output shaft.

Control valve

Controls oil pressure from the oil pump to the pressure suitable for the line pressure

control system, shift control system, lock-up control system and lubrication system.

Pressure regulator valve

Adjusts the discharge pressure from the oil pump to the optimum pressure (line pres-

sure) corresponding to the driving condition.

Torque converter regulator valve

Adjusts the feed pressure to the torque converter to the optimum pressure correspond-

ing to the driving condition.

Pilot valve

Adjusts line pressure and produces a constant pressure (pilot pressure) necessary for

activating each solenoid valve.