Nissan Note E12. Manual - part 441

MA-12

< PERIODIC MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

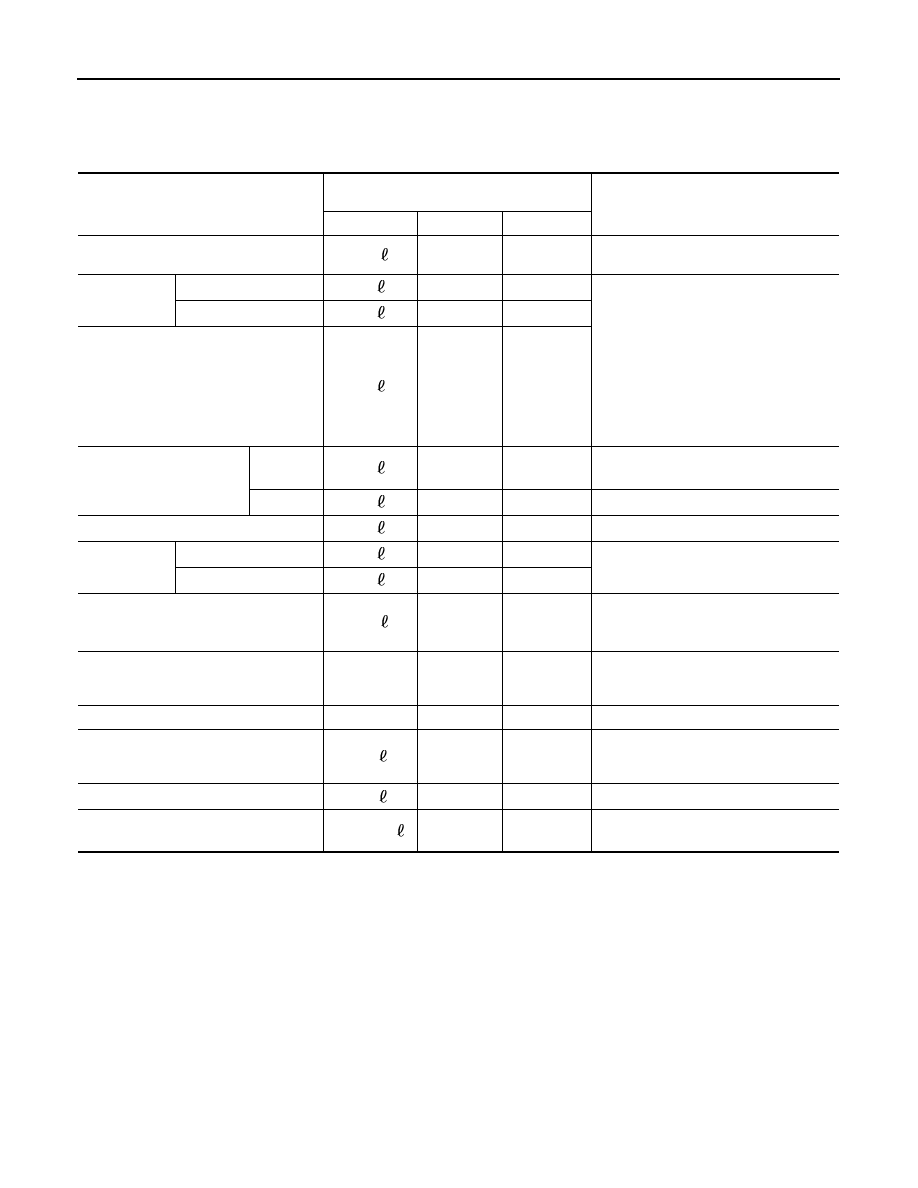

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants

INFOID:0000000009452309

*1: For additional information, see “SAE Viscosity Number”.

*2: Use Genuine NISSAN Engine Coolant (blue) or equivalent in its quality, in order to avoid possible aluminum corrosion within the

engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*3: Use only Genuine NISSAN CVT Fluid NS-3. Using transmission fluid other than Genuine NISSAN CVT Fluid NS-3 will damage the

CVT, which is not covered by the warranty.

*4: If Genuine NISSAN Manual Transmission Fluid (MTF) HQ Multi is not available, API GL-4, Viscosity SAE 75W-85 may be used as a

temporary replacement. However, use Genuine NISSAN Manual Transmission Fluid (MTF) HQ Multi as soon as it is available.

*5: For further information, see “Air conditioning specification label”.

SAE Viscosity Number

INFOID:0000000009452310

GASOLINE ENGINE

• 10W-30 is preferable.

Description

Capacity

(Approximate)

Recommended Fluids/Lubricants

Liter

US measure

Imp measure

Fuel

41.0

10-7/8 gal

9.0 gal

Unleaded regular gasoline with an octane

rating of at least 87 AKI (RON 91)

Engine oil

Drain and refill

With oil filter change

3.5

3-3/4 qt

3-1/8 qt

For Mexico:

Genuine NISSAN engine oil*

1

API grade SL, SM or SN*

1

ILSAC grade GF-3, GF-4 or GF-5*

1

Viscosity SAE 10W-30*

1

Except for Mexico:

Genuine NISSAN engine oil*

1

API grade SL, SM or SN*

1

ILSAC grade GF-3, GF-4 or GF-5*

1

Without oil filter change

3.2

3-3/8 qt

2-7/8 qt

Dry engine (Overhaul)

3.5

3-3/4 qt

3-1/8 qt

Cooling system (with reser-

voir)

CVT

7.3

7-3/4 qt

6-3/8 qt

Genuine NISSAN Engine Coolant (blue)

or equivalent in its quality*

2

M/T

6.7

7-1/8 qt

5-7/8 qt

Reservoir tank

0.7

3/4 qt

5/8 qt

CVT fluid

With oil cooler

7.1

7-1/2 qt

6-1/4 qt

Genuine NISSAN CVT Fluid NS-3

*3

Without oil cooler

6.9

7-1/4 qt

6-1/8 qt

Manual transaxle fluid gear oil

2.67

5-5/8 pt

4-3/4 pt

Genuine NISSAN Manual Transmission

Fluid (MTF) HQ Multi 75W-85 or equiva-

lent*

4

Brake and clutch fluid

—

—

—

Genuine NISSAN Brake Fluid, or equiva-

lent DOT 3

(US FMVSS No. 116)

Multi-purpose grease

—

—

—

NLGI No. 2 (Lithium soap base)

Windshield washer fluid

2.5

2-5/8 qt

2-1/4 qt

Genuine NISSAN Windshield Washer

Concentrate Cleaner & Antifreeze or

equivalent

Air conditioner system refrigerant

0.4

0.88 lb

0.88 lb

HFC-134a (R-134a) *5

Air conditioner system oil

110 - 130

3.9 - 4.6 fl oz

3.9 - 4.6 fl oz

NISSAN A/C System Oil Type DH-PR

(Type R) or equivalent *

5