Nissan Note E12. Manual - part 229

P0850 PNP SWITCH

EC-255

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Proceed to

.

NO

>> INSPECTION END

5.

PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to

EC-255, "Component Function Check"

.

NOTE:

Use component function check the overall function of the park/neutral position (PNP) signal circuit. During this

check, a 1st trip DTC might not be confirmed.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Proceed to

.

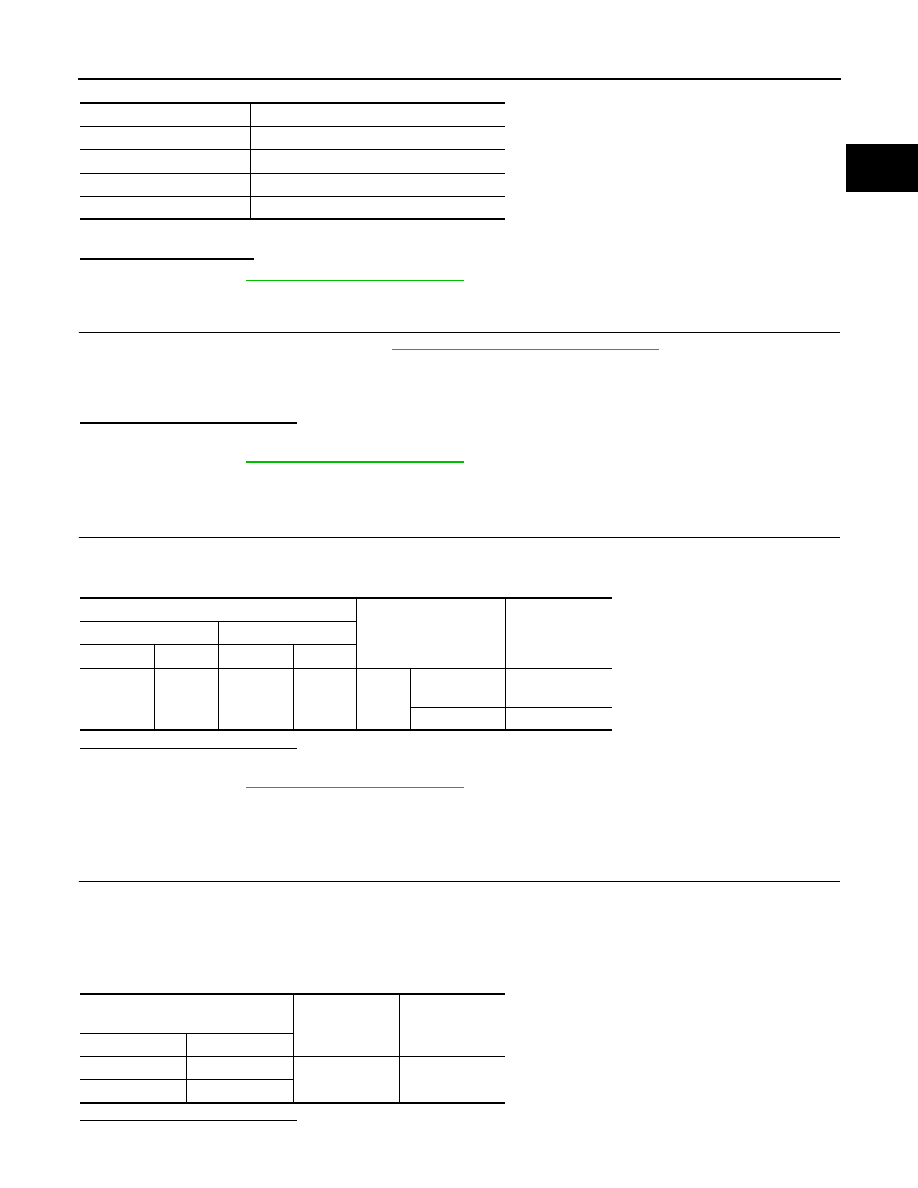

Component Function Check

INFOID:0000000009022604

1.

PERFORM COMPONENT FUNCTION CHECK

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Proceed to

.

Diagnosis Procedure

INFOID:0000000009022605

1.

CHECK TRANSMISSION RANGE SWITCH (CVT) OR PARK/NEUTRAL POSITION (PNP) SWITCH (M/T)

POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect transmission range switch (CVT) or PNP switch (M/T) harness connector.

3. Turn ignition switch ON.

4. Check the voltage between transmission range switch (CVT) or PNP switch (M/T) harness connector and

ground.

Is the inspection result normal?

YES

>> GO TO 3.

ENG SPEED

1,500 - 6,375 rpm

COOLAN TEMP/S

More than 70

°C (158°F)

B/FUEL SCHDL

4 (CVT) or 2.75 (M/T) - 31.8 msec

VHCL SPEED SE

More than 64 km/h (40 mph)

Shift lever

Suitable position

ECM

Condition

Voltage

+

−

Connector

Terminal

Connector

Terminal

F11

69

(PNP

signal)

E16

108

Shift

lever

P or N (CVT)

Neutral (M/T)

Battery voltage

Except above

Approx. 0 V

Transmission range switch (CVT) /

PNP switch (M/T)

Ground

Voltage

Connector

Terminal

F52 (CVT)

7

Ground

Battery voltage

F24 (M/T)

2