Nissan Note E12. Manual - part 180

DIAGNOSIS SYSTEM (ECM)

EC-59

< SYSTEM DESCRIPTION >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

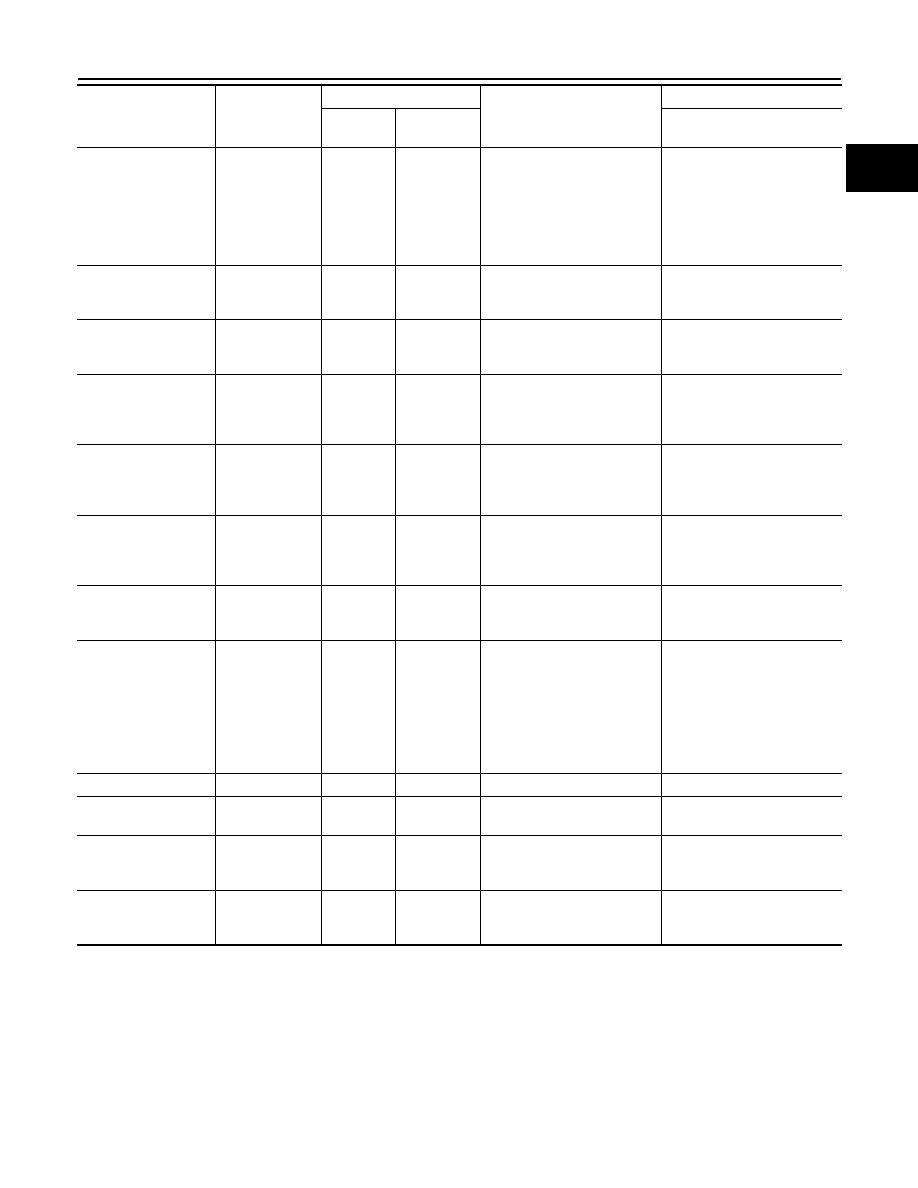

WORK SUPPORT MODE

Work Item

LO SPEED CUT

NON/CUT

Indicates the vehicle cruise

condition.

NON: Vehicle speed is main-

tained at the ASCD set speed.

CUT: Vehicle speed de-

creased to excessively low,

and ASCD operation is cut off.

AT OD MONITOR

ON/OFF

Indicates [On/Off] condition of

CVT O/D according to the in-

put signal from the TCM.

AT OD CANCEL

ON/OFF

Indicates [On/Off] condition of

CVT O/D cancel request sig-

nal.

CRUISE LAMP

ON/OFF

Indicates [ON/OFF] condition

of CRUISE lamp determined

by the ECM according to the

input signals.

SET LAMP

ON/OFF

Indicates [ON/OFF] condition

of SET lamp determined by

the ECM according to the in-

put signals.

KICKDOWN POS

ON/OFF

Indicates [ON/OFF] condition

of kickdown determined by

the ECM according to the in-

put signals.

CLUTCH P/P SW

ON/OFF

Indicates [ON/OFF] condition

clutch pedal position switch

signals.

Models other than M/T mod-

els always display OFF.

VTC DTY EX B1

%

• The control value of the ex-

haust valve timing control

solenoid valve (determined

by ECM according to the in-

put signals) is indicated.

• The advance angle be-

comes larger as the value

increases.

THRTL STK CNT B1

—

Not used.

EOP SENSOR

mV

The signal voltage of EOP

sensor is displayed.

HO2 S2 DIAG2(B1)

INCMP/CMPLT

NOTE:

The item is indicated, but not

used.

A/F SEN1 DIAG2(B1)

INCMP/CMPLT

NOTE:

The item is indicated, but not

used.

Monitored item

Unit

Monitor Item Selection

Description

Remarks

MAIN

SIGNALS

ECU INPUT

SIGNALS