Nissan Pathfinder (2008 year). Manual - part 608

TM-206

< ON-VEHICLE REPAIR >

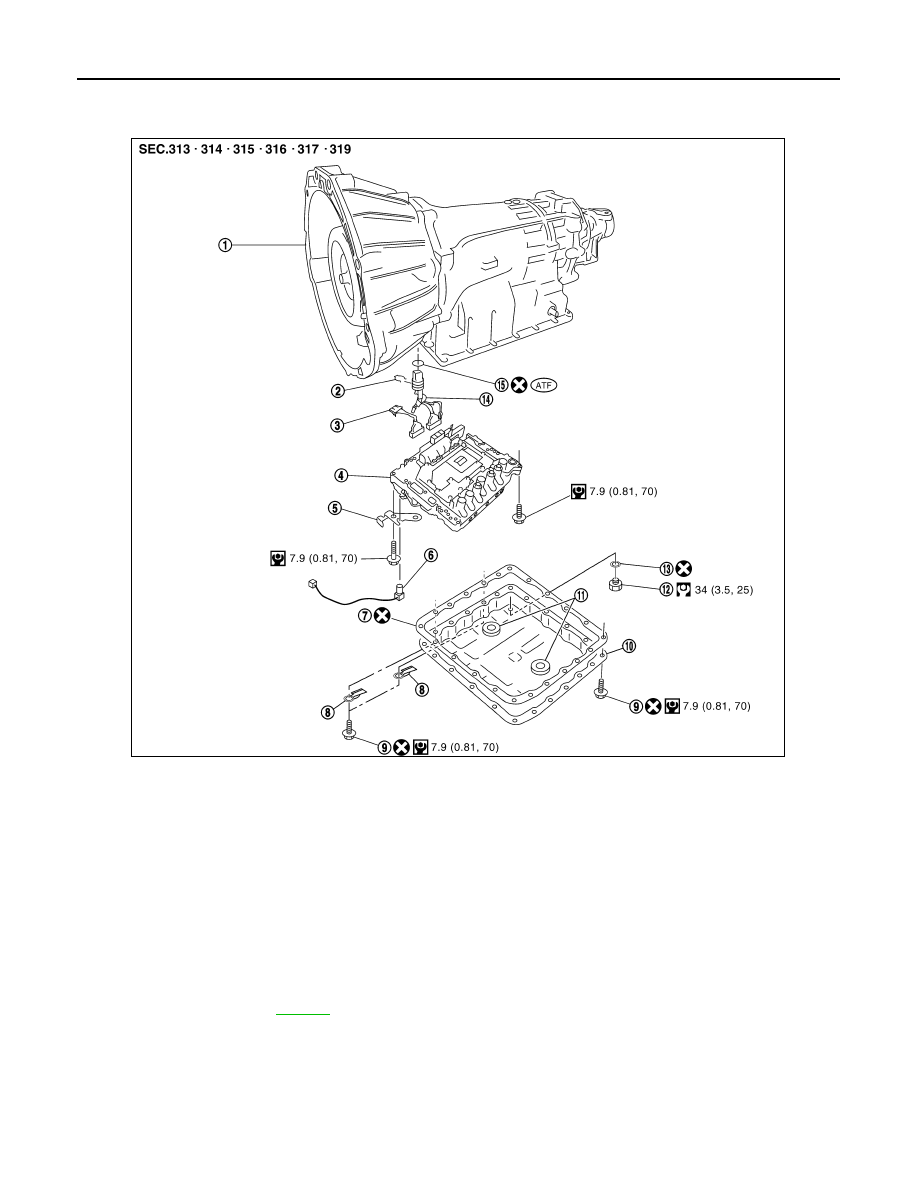

CONTROL VALVE WITH TCM

Exploded view

INFOID:0000000001724671

Removal and Installation

INFOID:0000000001724673

CONTROL VALVE WITH TCM REMOVAL AND INSTALLATION

Removal

1.

Disconnect negative battery terminal.

2.

Drain A/T fluid. Refer to

.

3.

Disconnect A/T assembly harness connector.

1.

Transmission

2.

Snap ring

3.

Sub-harness

4.

Control valve with TCM

5.

Bracket

6.

A/T fluid temperature sensor 2

7.

Oil pan gasket

8.

Clips

9.

Oil pan bolt

10. Oil pan

11.

Magnet

12. Drain plug

13. Drain plug gasket

14. Terminal cord assembly

15. O-ring

AWDIA0024ZZ