Nissan Pathfinder (2008 year). Manual - part 205

DLN-224

< COMPONENT DIAGNOSIS >

[TRANSFER: TX15B]

P1817 ACTUATOR MOTOR

4.

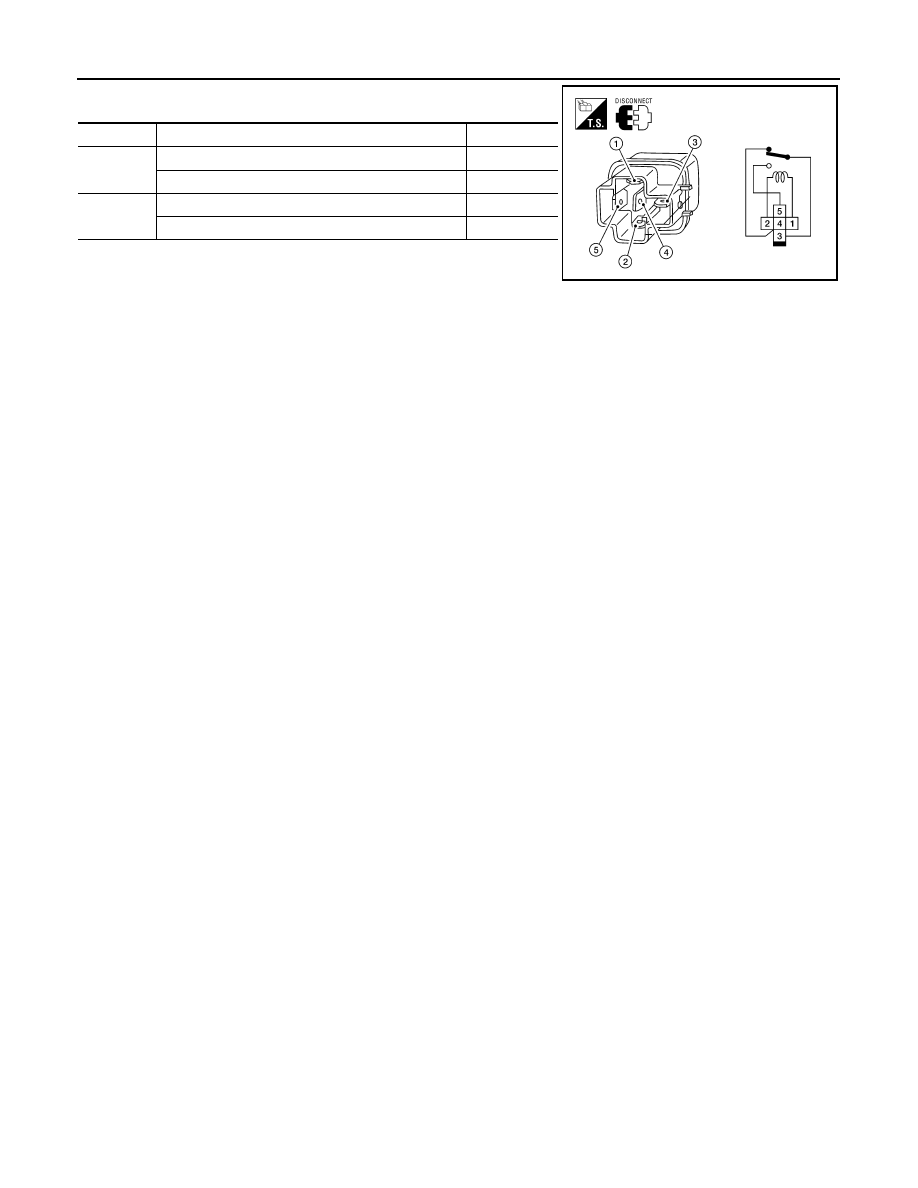

Check continuity between relay terminals 3 and 4, and 3 and 5.

5.

If the inspection results are abnormal replace the transfer shift

high or low relay.

Terminal

Condition

Continuity

3 - 4

12V direct current supply between terminals 1 and 2

No

OFF

Yes

3 - 5

12V direct current supply between terminals 1 and 2

Yes

OFF

No

LDIA0099E