Nissan Pathfinder (2008 year). Manual - part 129

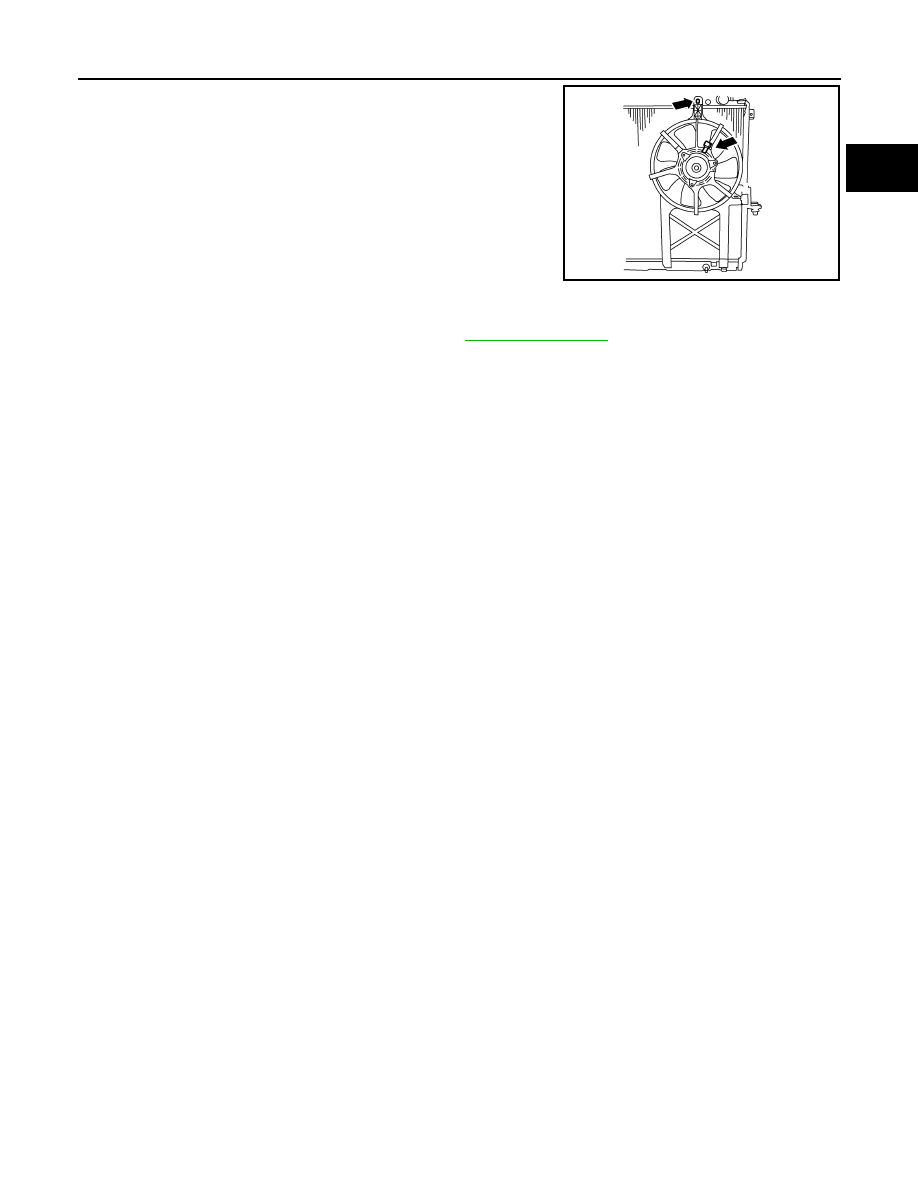

ENGINE COOLING FAN

CO-21

< ON-VEHICLE REPAIR >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

8.

Disconnect harness connector from fan motor.

9.

Remove the bolt and remove the fan grille and motor assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Cooling fan is controlled by ECM. For details, refer to

.

AWBIA0148ZZ