Nissan Pathfinder (2008 year). Manual - part 84

BRAKE PIPING AND HOSE

BR-19

< REMOVAL AND INSTALLATION >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

2.

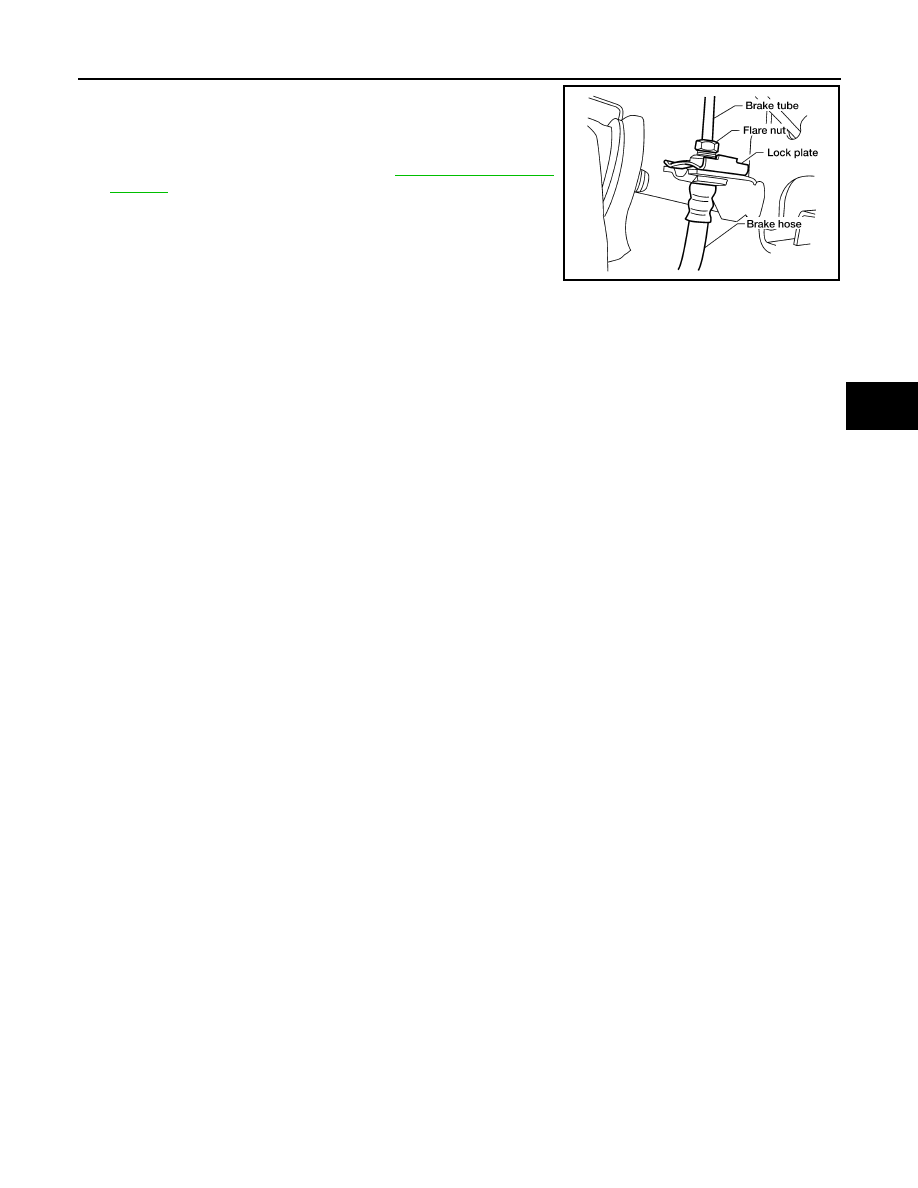

Insert brake hose end through bracket, then secure it to bracket

with lock plate.

3.

Install brake tube to brake hose, then tighten flare nut to the

specified torque using a suitable tool.

4.

Refill brake fluid and bleed air. Refer to

Inspection After Installation

INFOID:0000000001297437

CAUTION:

If a leak is detected at the connections, retighten it or, if necessary, replace the damaged part.

1.

Check brake lines (tubes and hoses), and connections for fluid leaks, damage, twist, deformation, contact

with other parts, and loose connections. Replace any damaged parts.

2.

While depressing brake pedal under a force of 785 N (80 kg-f, 177 lb-f) with engine running for approxi-

mately 5 seconds, check for fluid leaks from each part.

LFIA0238E