Nissan Pathfinder (2008 year). Manual - part 82

PRECAUTIONS

BR-3

< PRECAUTION >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001297388

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake System

INFOID:0000000001297389

• Recommended fluid is Genuine NISSAN Super Heavy Duty Brake Fluid or equivalent. Refer to

• Do not reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas.

• To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

• Do not use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

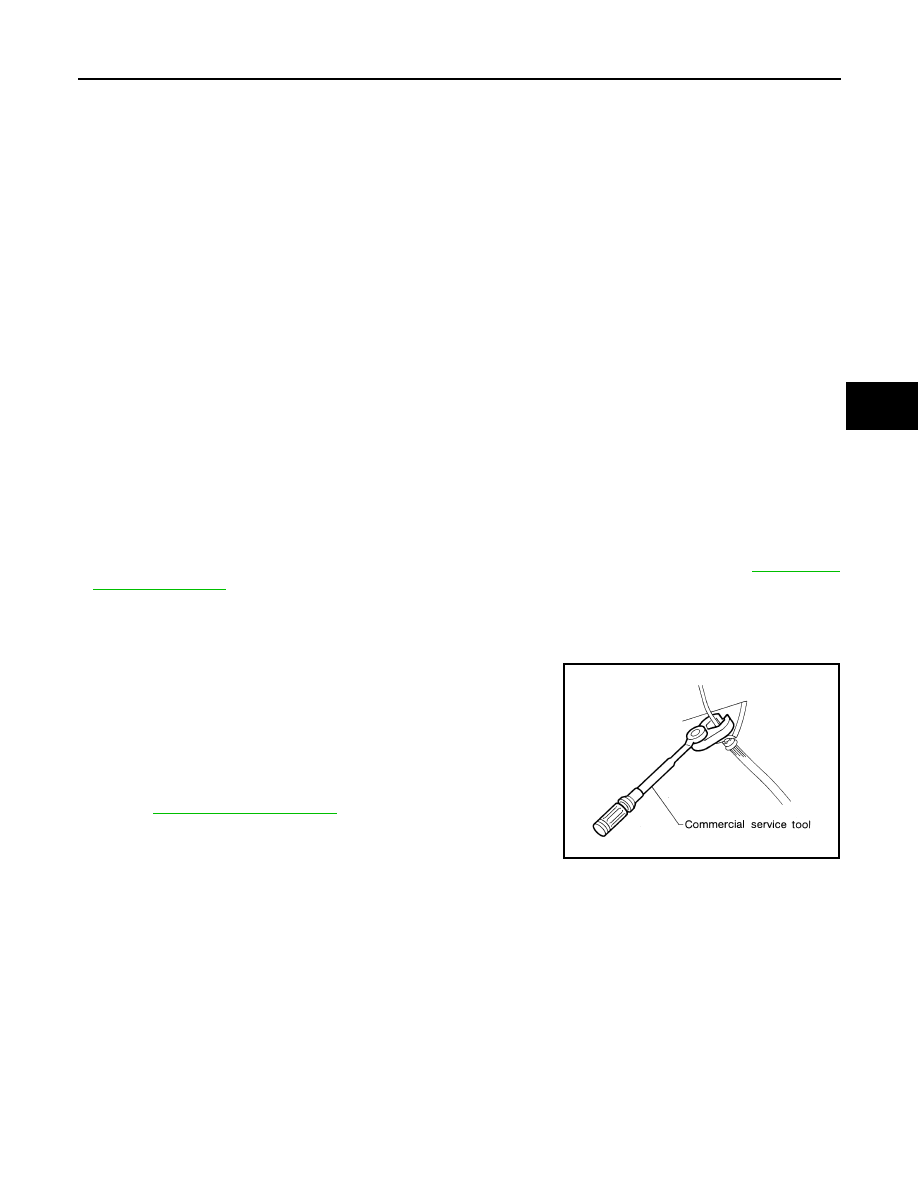

• Use flare nut wrench when removing and installing brake tube.

• Always check tightening torque when installing brake lines.

• Before working, turn ignition switch to OFF and disconnect con-

nectors for ABS actuator and electric unit (control unit) or battery

negative terminal.

• Burnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage.

Refer to

.

WARNING:

• Clean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

SBR686C