Qashqai J11. Transaxle & Transmission - part 11

TM-162

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F52A]

TRANSAXLE ASSEMBLY

4WD : Assembly

INFOID:0000000010288517

1.

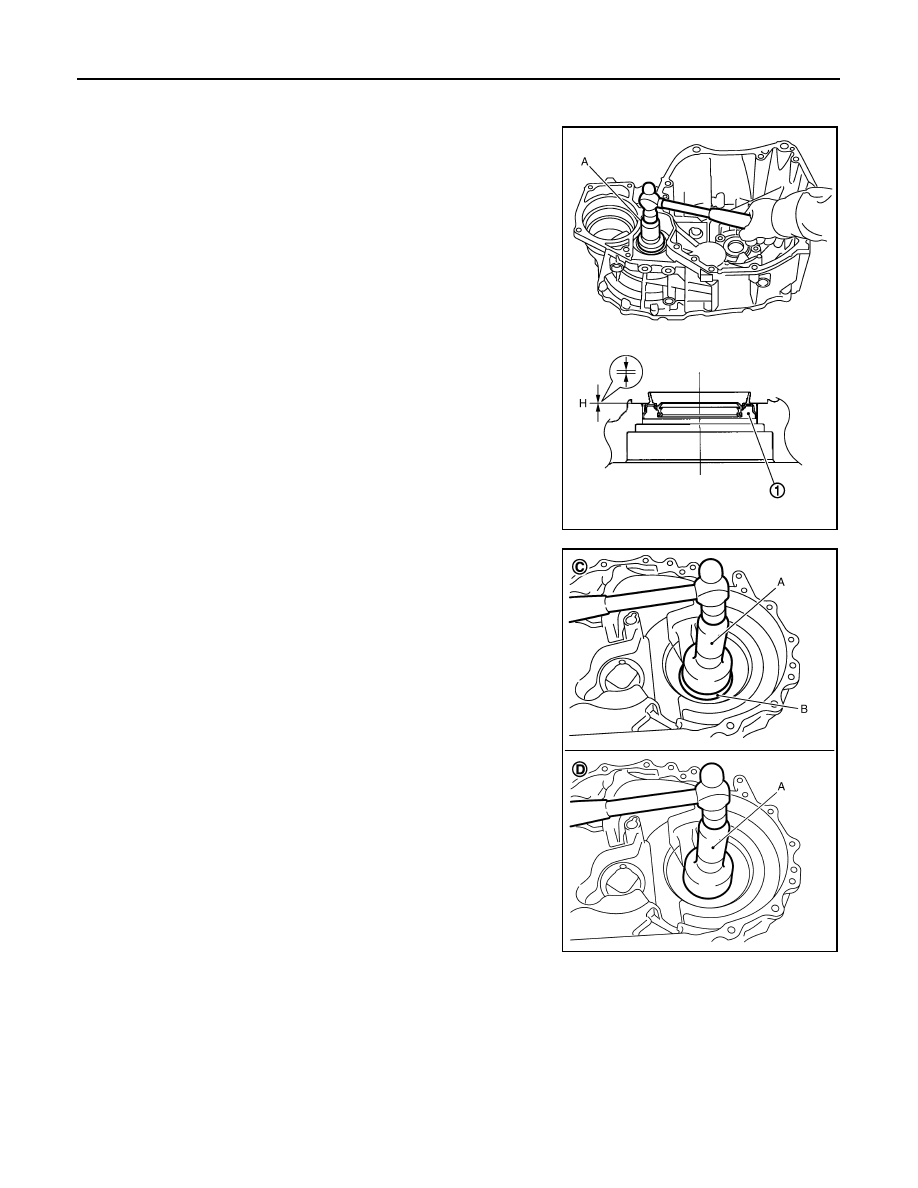

Install differential side oil seal (1) to clutch housing using the drift

(A) [SST: ST33400001].

CAUTION:

• Never reuse differential side oil seal.

• When installing, never incline differential side oil seal.

• Never damage clutch housing.

2.

Install differential side bearing outer race (clutch housing side) to

clutch housing using the drifts.

CAUTION:

• Never reuse differential side bearing and differential side

bearing outer race.

• Replace differential side bearing and differential side

bearing outer race as a set.

Dimension “H”

: -0.5 - 0.5 mm (-0.020 - 0.020 in)

JPDIC0077ZZ

A

: Drift [SST: ST30720000]

B

: Drift [SST: KV40105320]

C

: M9R

D

: MR2ODE

JPDIC0132ZZ