Isuzu N-Series. Manual - part 611

6C-14 ENGINE FUEL

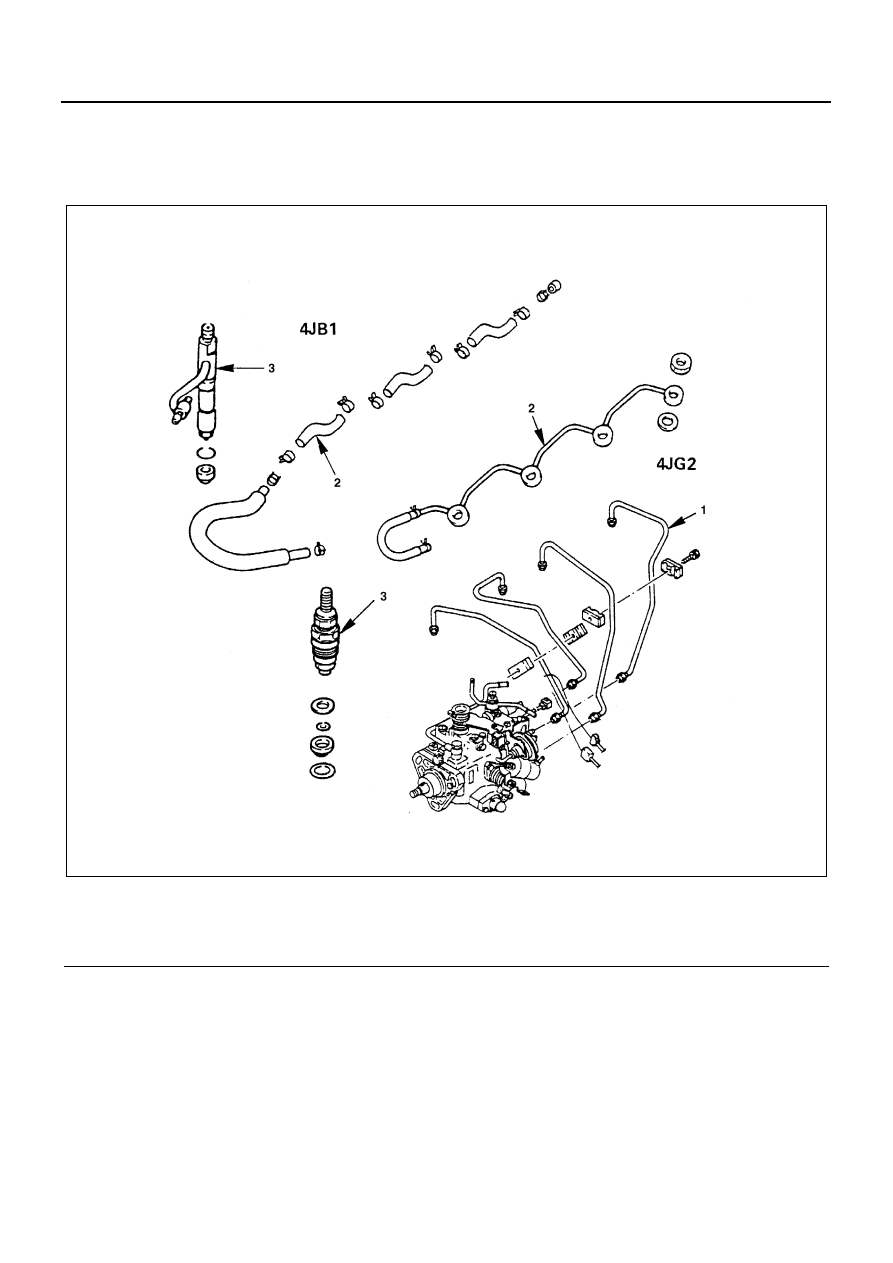

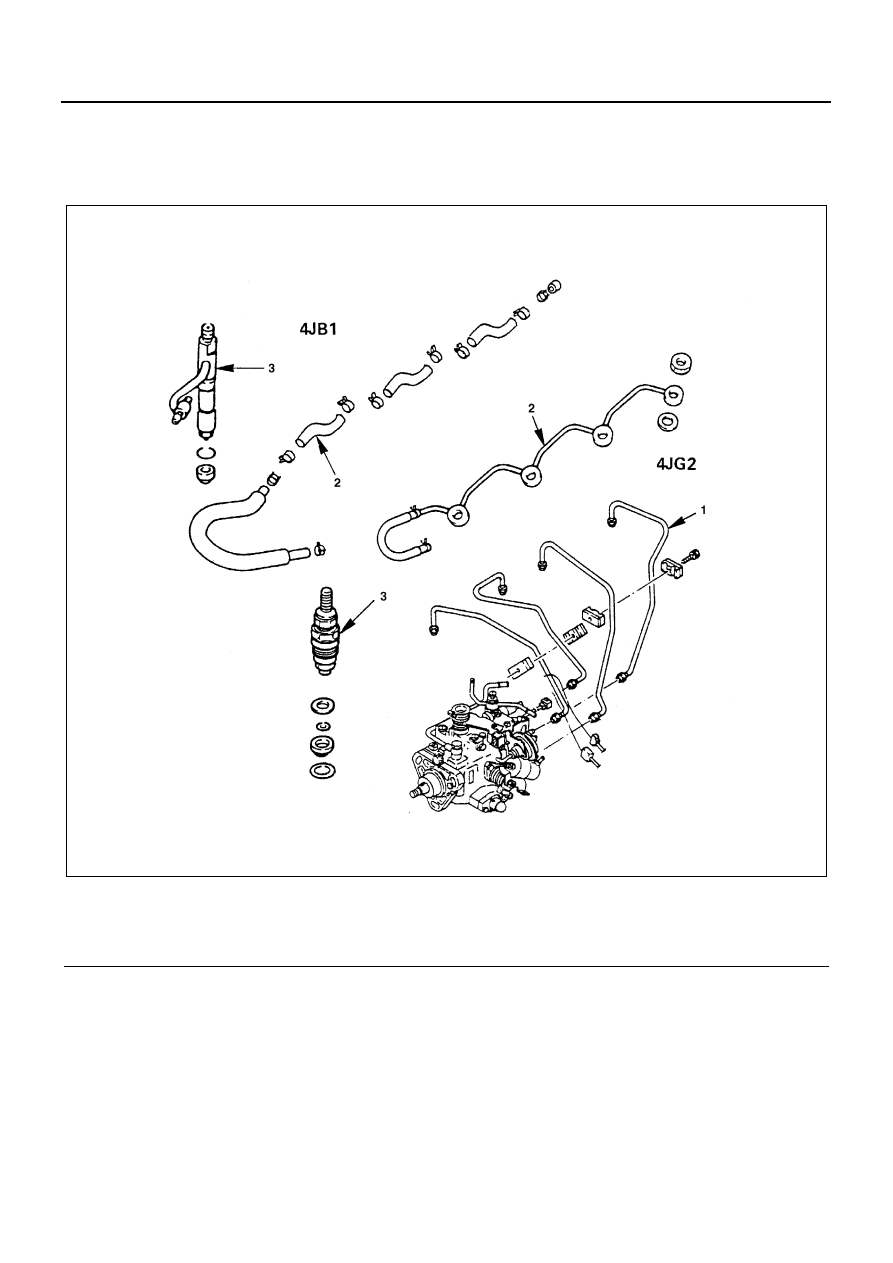

INJECTION NOZZLE

Component

4JB1 / 4JG2

Legend

1. Injection pipe

3. Injection nozzle

2. Leak off pipe or hose

N6A3401E

|

|

|

6C-14 ENGINE FUEL INJECTION NOZZLE Component 4JB1 / 4JG2 Legend 1. Injection pipe 3. Injection nozzle 2. Leak off pipe or hose N6A3401E |