Isuzu N-Series. Manual - part 524

6C-4 Fuel System

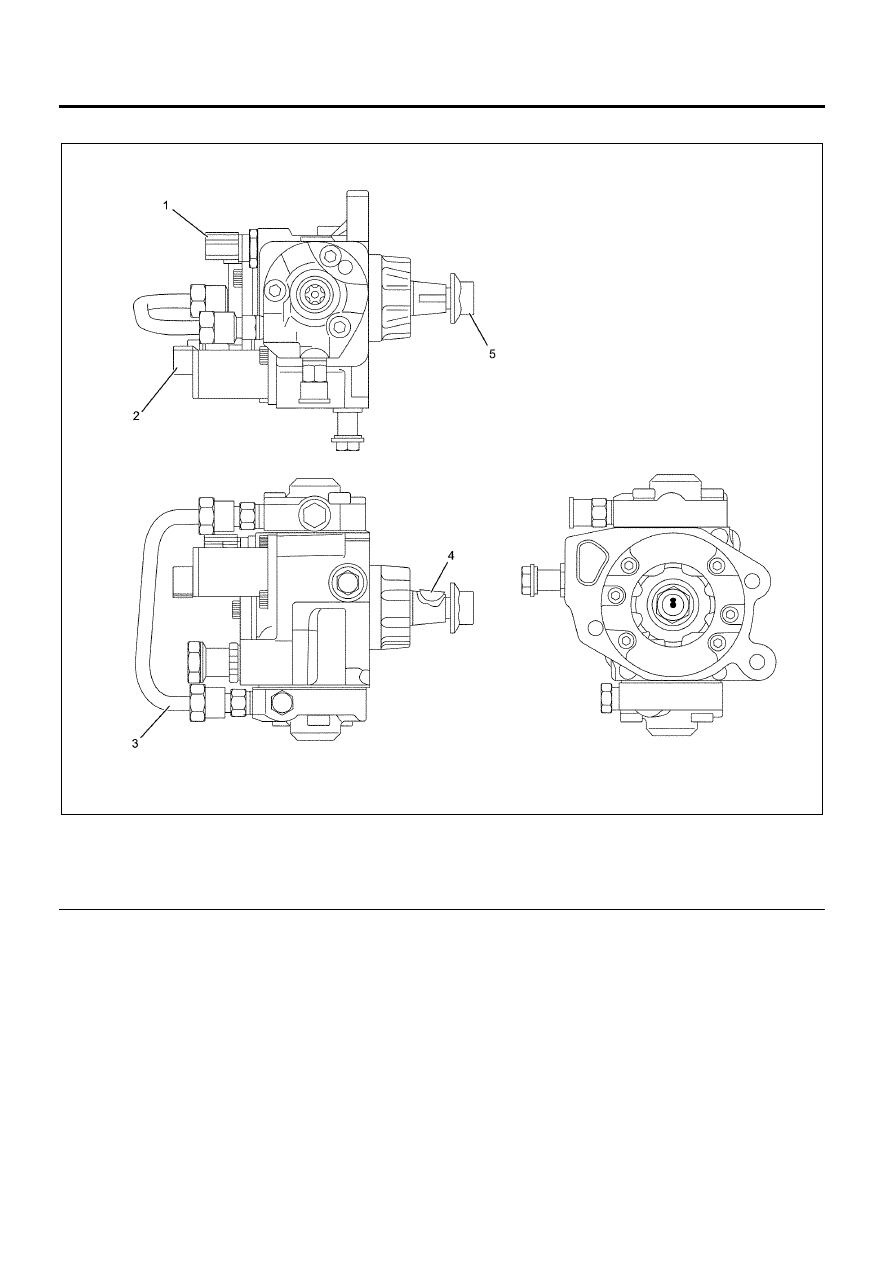

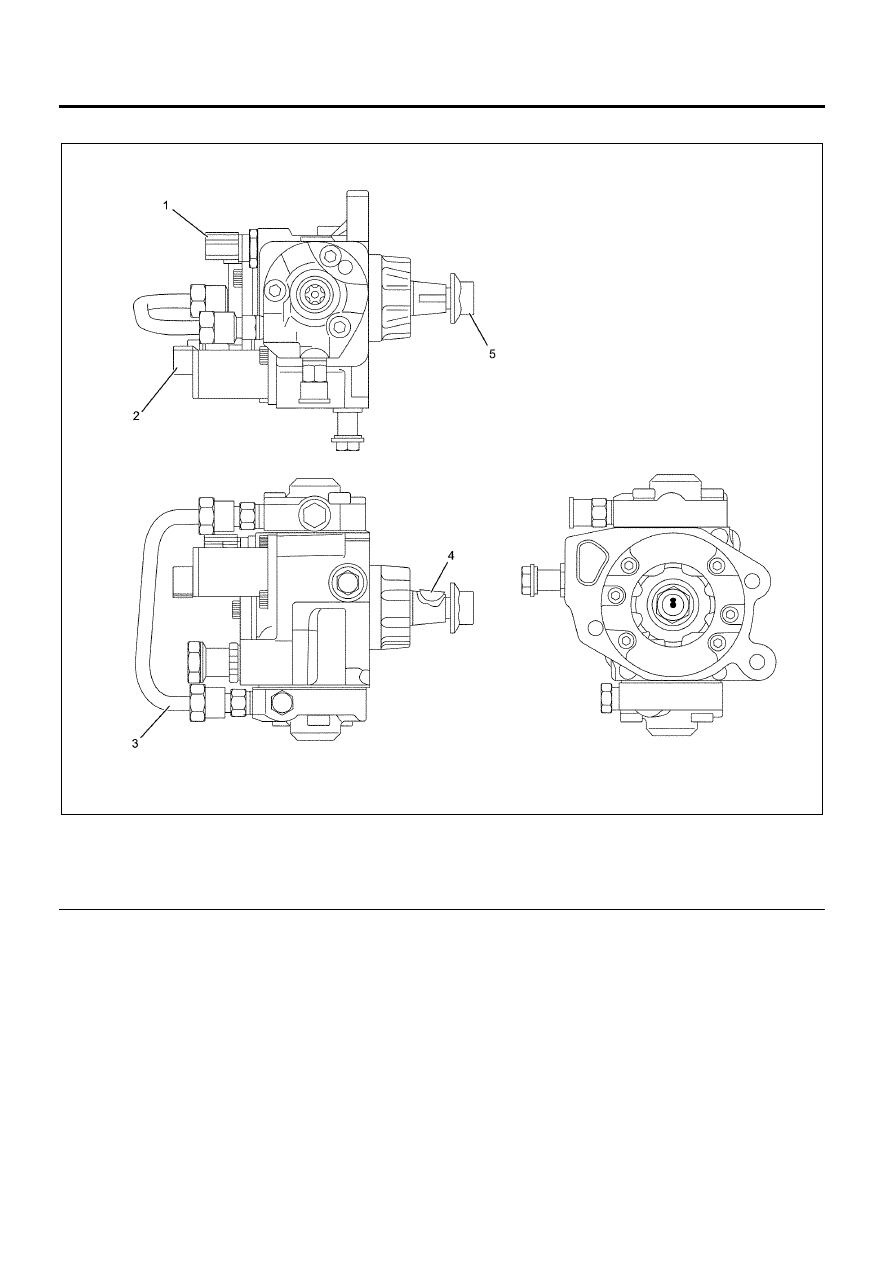

Fuel Supply Pump

Legend

1. Fuel Temperature Sensor

2. Fuel Rail Pressure Regulator

3. High Pressure Piping

4. Camshaft Key

5. Camshaft Nut

N6A6359E

|

|

|

6C-4 Fuel System Fuel Supply Pump Legend 1. Fuel Temperature Sensor 4. Camshaft Key

N6A6359E |