Isuzu N-Series. Manual - part 500

Engine Mechanical (4HK1-TC) 6A-105

• Apply engine oil on the piston pin. Use your

finger to push it in hole of the piston and rotate

it. If the pin smoothly rotates without instability,

the clearance is normal. If there is instability,

measure the clearance. If the clearance

exceeds the limit, replace the piston and the

piston pin.

11. Remove the bush.

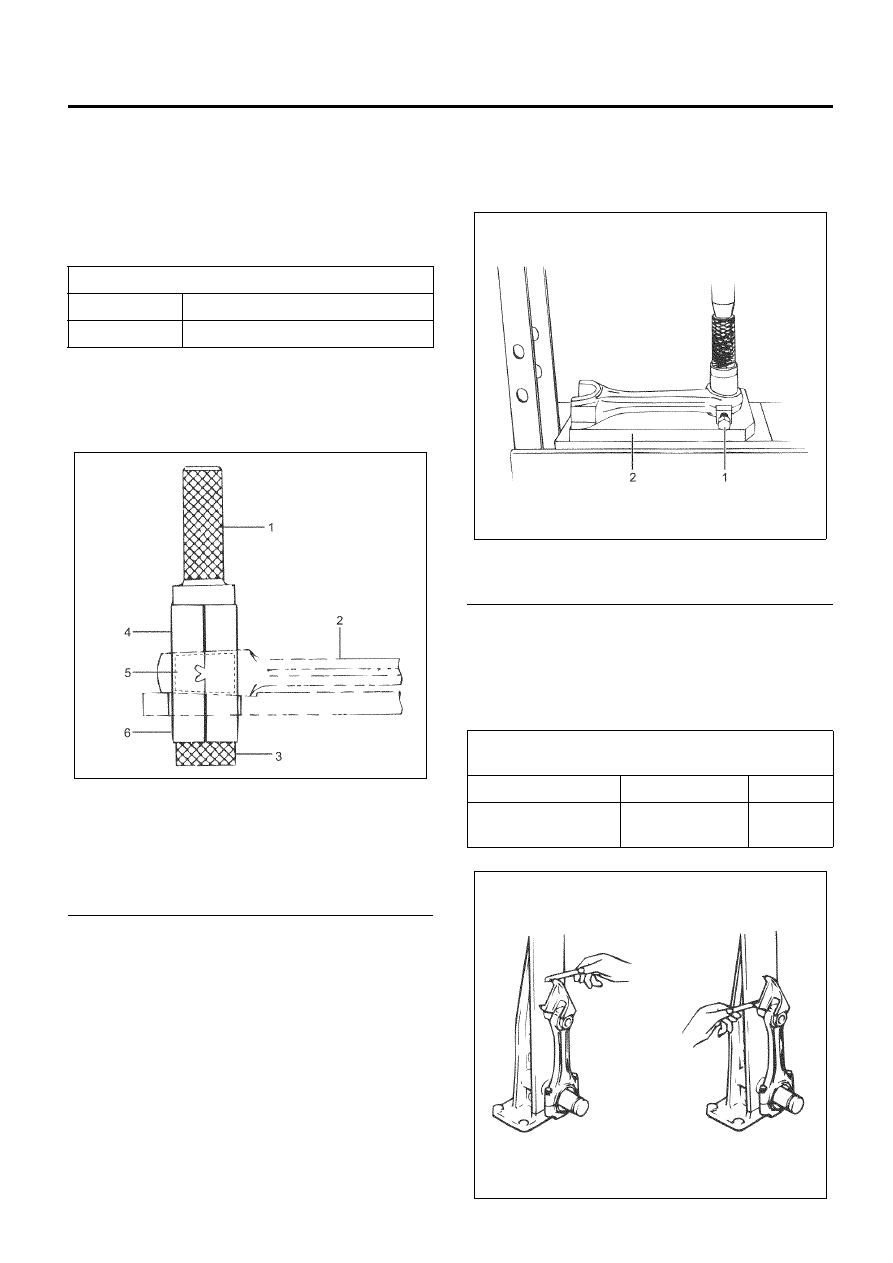

• Set the collar, connecting rod and collar on the

setting bar as shown in the drawing.

• Tighten the nut.

Legend

1. Setting Bar

2. Connecting Rod

3. Nut

4. Collar

5. Bush

6. Collar

• Place the connecting rod bush replacer base on

press, tighten the fixation bolt.

• Use the bench press to replace the bush.

Special tool

Connecting rod bush replacer: 5-8840-2340-0

(EN-47682)

Legend

1. Bolt

2. Connecting Rod Bush Replacer

12. Measure the connecting rod alignment.

• Use a connecting rod aligner to measure the

parallelism of the big end hole and the small

end hole. If the measured value exceeds the

limit, replace it.

Piston pin and piston pin hole clearance

mm (in)

Standard

0.004 – 0.017 (0.00016 – 0.00067)

Limit

0.04 (0.0016)

N6A6199E

Connecting rod alignment

(par length of 100 mm (3.94 in))

mm (in)

Standard

Limit

Distortion and

Parallelism

0.05 (0.002)

0.20

(0.008)

N6A6200E

N6A6201E