Isuzu N-Series. Manual - part 499

Engine Mechanical (4HK1-TC) 6A-101

Caution:

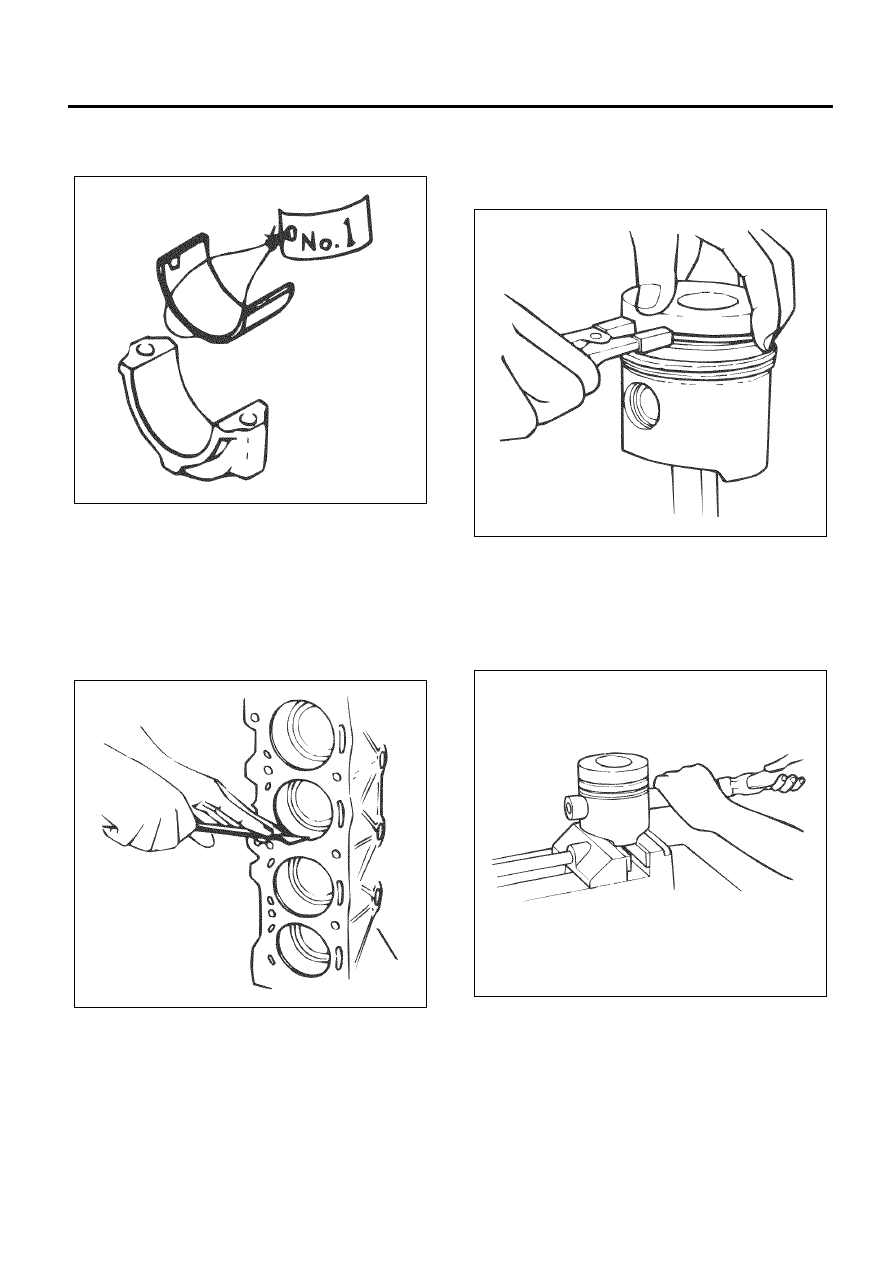

Sort the removed bearings according to cylinders by

using tags.

7. Remove the piston and connecting rod.

• Remove carbon on the upper side of the

cylinder liner with a scraper.

• Pull out the piston and connecting rod towards

the cylinder head.

Caution:

Be sure not to damage the oil jet and cylinder liner

when pushing out the connecting rod.

8. Remove the connecting rod bearing.

Caution:

Arrange the bearings in the order of cylinders. Be sure

to put them back to the original cylinders.

Disassembly

1. Remove the piston ring.

• Use ring pliers to remove the piston ring.

Caution:

Sort the piston rings in the order of cylinders when

reusing them so that they will not be confused with the

pistons and piston rings of other cylinders.

2. Remove the snap ring.

3. Remove the piston pin.

Caution:

Sort the disassembled piston pins, pistons and

connecting rods together in the order of cylinders.

4. Remove the connecting rods from the piston.

5. Piston

• Clean carbon carefully that is adhered to the

head of the piston and the groove of the piston

ring.

N6A6186E

N6A6187E

N6A6188E

N6A6189E