Isuzu N-Series. Manual - part 419

6E-12 EMISSION AND ELECTRICAL DIAGNOSIS

Parts for Electrical Circuit

Wiring

Wire Color

All wires have color-coded insulation.

Wires belonging to a system’s main harness will have a

single color. Wires belonging to a system’s sub circuits

will have a colored stripe. Striped wires use the following

code to show wire size and colors.

Abbreviations are used to indicate wire color within a cir-

cuit diagram.

Refer to the following table.

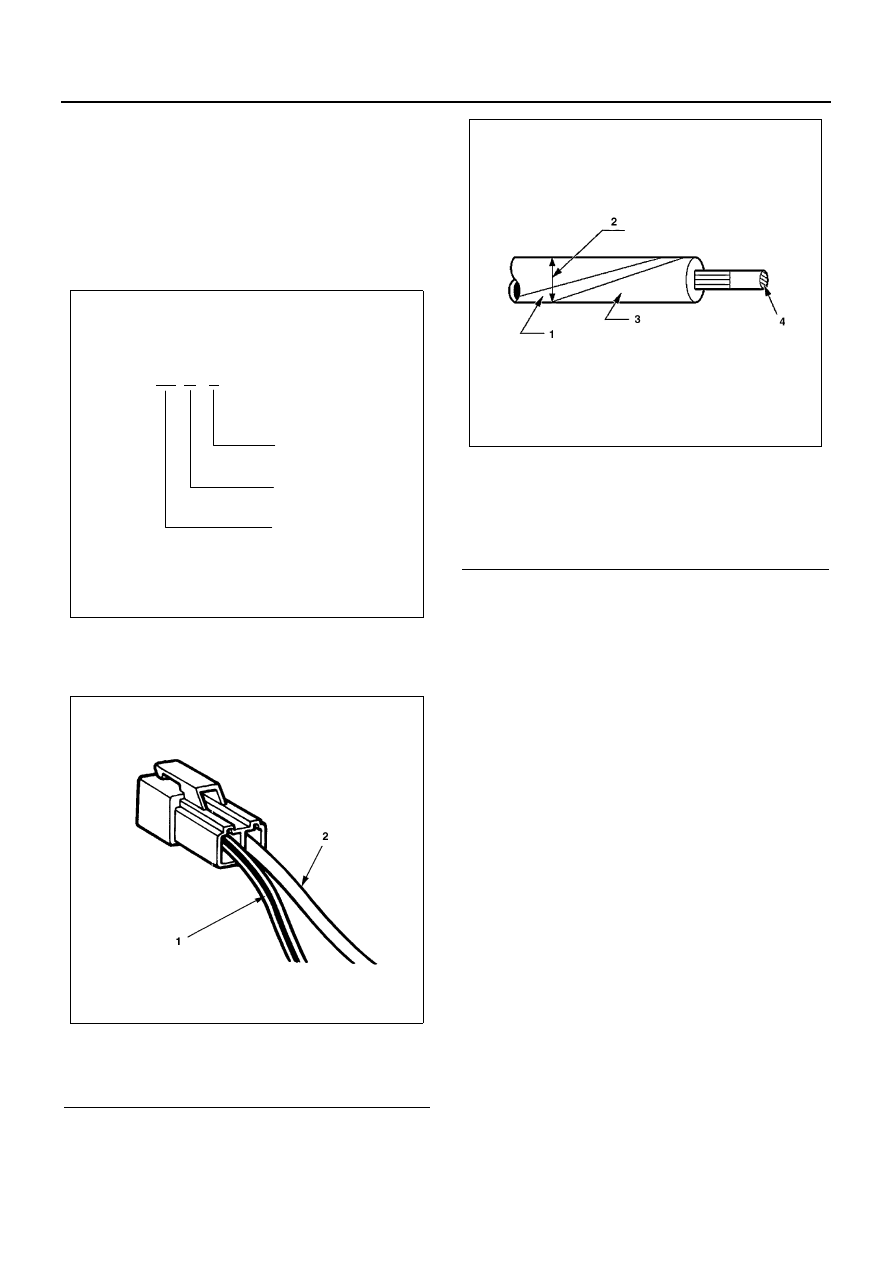

Legend

1. Colored stripe

2. Single color

Example: 0.5 G R

Red (Stripe color)

Green (Base color)

Wire size (0.5 mm)

N6A1416E

N6A1125E

Legend

1. Stripe color

2. Outside diameter

3. Base color

4. Cross sectional area

N6A1126E