Isuzu N-Series. Manual - part 329

6A-58 ENGINE MECHANICAL

3. Use a feeler gauge to measure the piston ring gap.

If the measured valve exceeds the specified limit,

the piston ring must be replaced.

Piston Ring and Piston Ring Groove Clearance

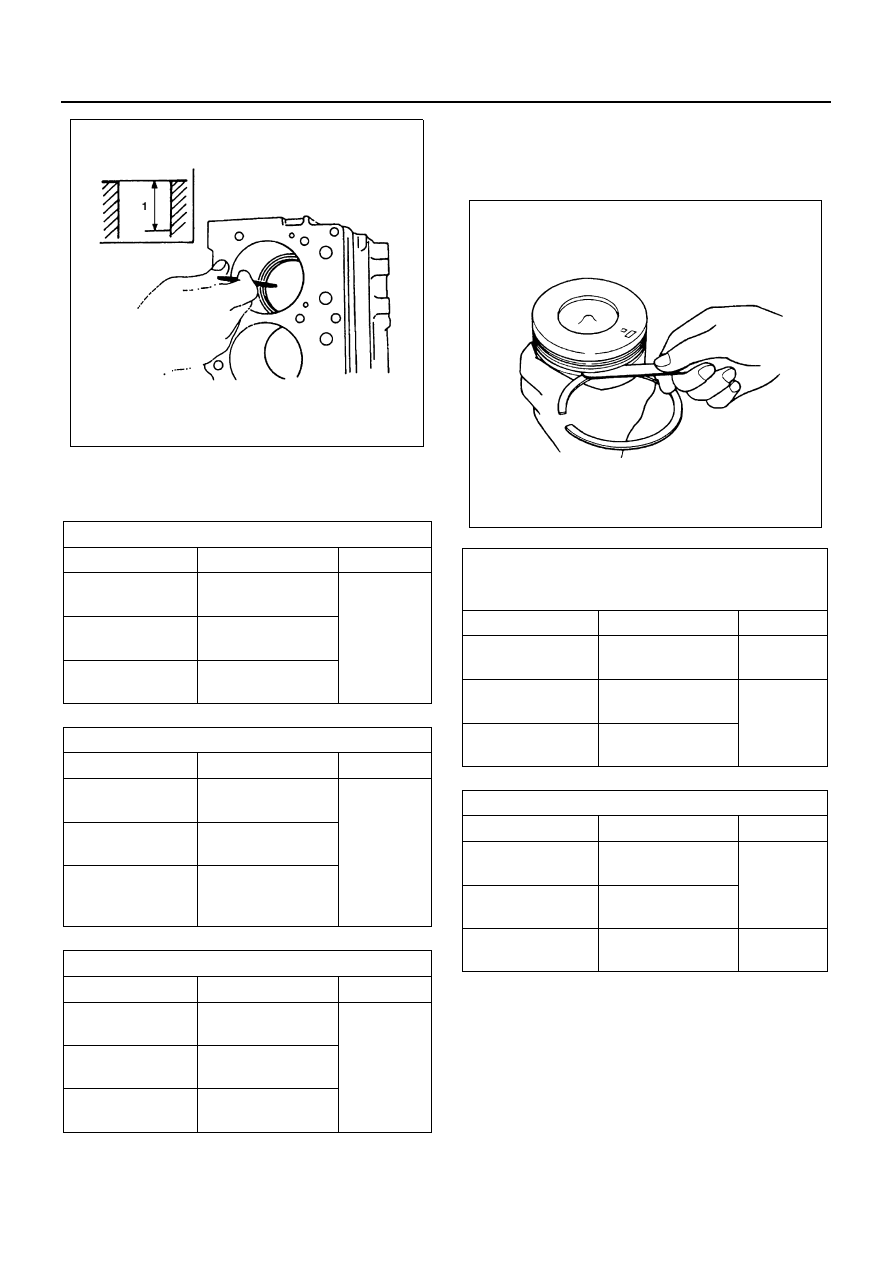

1. Use a feeler gauge to measure the clearance be-

tween the piston ring and the piston ring groove at

several points around the piston.

2. Visually inspect the piston ring grooves.

If a piston ring groove is damaged or distorted, the

piston must be replaced.

Piston Pin

Piston Pin Diameter

Use a micrometer to measure the piston pin outside di-

ameter at several points.

If the measured value is less than the specified limit, the

piston pin must be replaced.

Piston Ring Gap / 4HF1 / 4HF1-2

mm (in)

Standard

Limit

1st compression

ring gap

0.24 — 0.39

(0.0094 — 0.0153)

1.50

(0.0591)

2nd compression

ring gap

0.35 — 0.50

(0.0138 — 0.0197)

Oil ring gap

0.02 — 0.40

(0.0008 — 0.0157)

Piston Ring Gap / 4HG1 / 4HG1-T

mm (in)

Standard

Limit

1st compression

ring gap

0.24 — 0.39

(0.0094 — 0.0153)

1.50

(0.0591)

2nd compression

ring gap

0.35 — 0.50

(0.0138 — 0.0197)

Oil ring gap

0.15 — 0.35

(0.00591 —

0.0138)

Piston Ring Gap / 4HE1-TC

mm (in)

Standard

Limit

1st compression

ring gap

0.24 — 0.40

(0.0094 — 0.0157)

1.50

(0.0591)

2nd and 3rd com-

pression ring gap

0.30 — 0.450

(0.0118 — 0.0177)

Oil ring gap

0.20 — 0.40

(0.0078 — 0.0157)

N6A0259E

Piston Ring and Piston Ring Groove

Clearance / 4HF1, 4HF1-2, 4HG1,

4HG1-T

mm (in)

Standard

Limit

1st Compression

Ring

0.062 — 0.092

(0.0024 — 0.0036)

0.20

(0.0079)

2nd Compression

Ring

0.04 — 0.08

(0.0015 — 0.0031)

0.15

(0.0059)

Oil ring gap

0.02 — 0.06

(0.0008 — 0.0024)

Groove Clearance / 4HE1-TC

mm (in)

Standard

Limit

1st Compression

Ring

0.09 — 0.13

(0.0035 — 0.0051)

0.20

(0.0078)

2nd and 3rd Com-

pression Ring

0.09 — 0.13

(0.0035 — 0.0051)

Oil ring gap

0.03 — 0.07

(0.0012 — 0.0028)

0.15

(0.0059)

N6A0260E