Isuzu N-Series. Manual - part 318

6A-14 ENGINE MECHANICAL

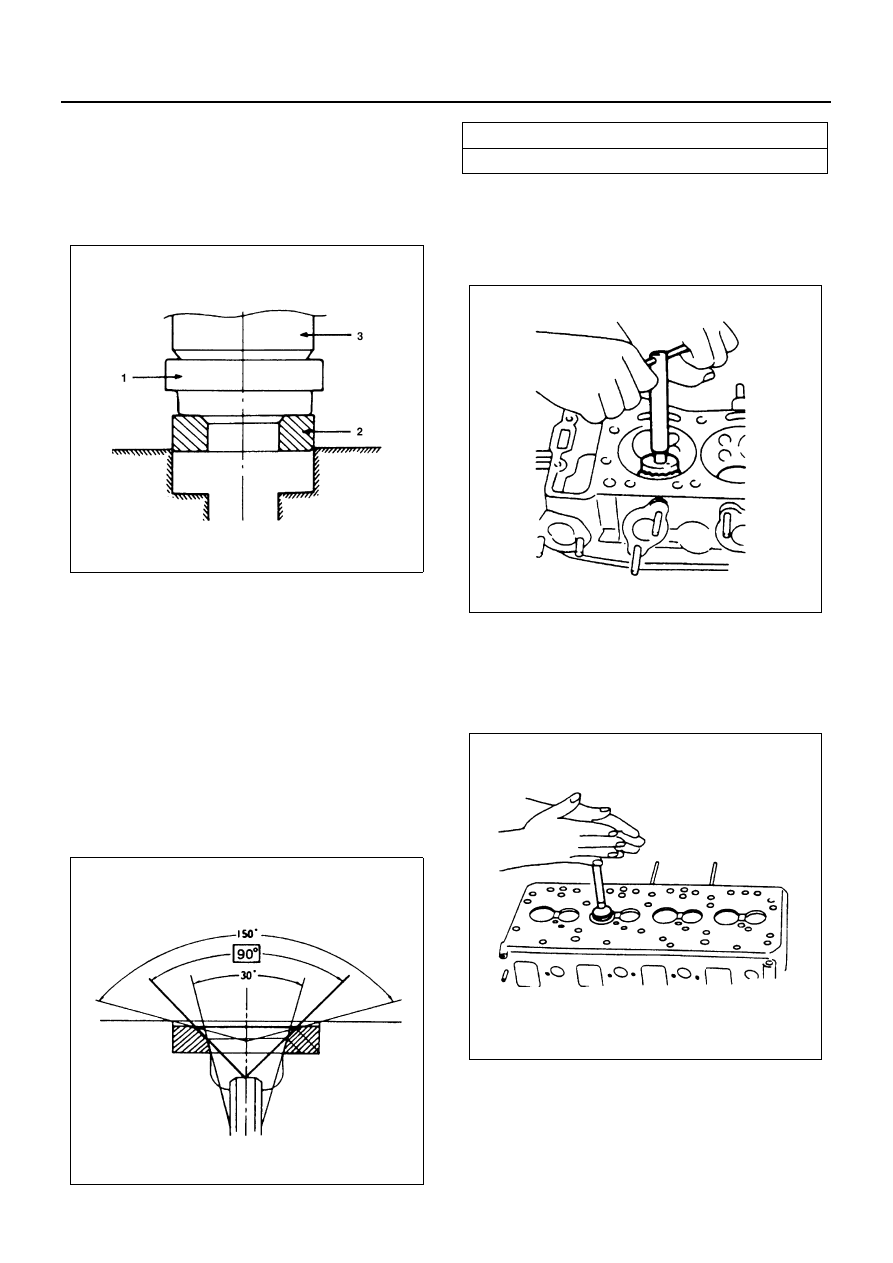

2. Use a bench press (3) to gradually apply pressure

to the attachment and press the valve seat insert

into place.

Caution:

Do not apply an excessive amount of pressure with the

bench press. Damage to the valve seat insert will result.

3. The valve should be lapped before final assembly

to ensure a good valve seal.

Above works refer to “Valve Seat Insert Correction”

section in this manual.

Valve Seat Insert Correction

1. Remove the carbon from the valve seat insert sur-

face.

2. Use a valve cutter (15

°, 45°, and 75° blades) to

minimize scratches and other rough areas. This

will bring the contact width back to the standard

value. Remove only the scratches and rough ar-

eas. Do not cut away too much. Take care not to

cut away unblemished areas of the valve seat sur-

face.

Notice:

Use an adjustable valve cutter pilot.

Do not allow the valve cutter pilot to wobble inside the

valve guide.

3. Apply abrasive compound to the valve seat insert

surface.

4. Insert the valve into the valve guide.

5. Turn the valve while tapping it to fit the valve seat

insert.

6. Check to see if the valve contact width is correct.

7. Check to see if the valve seat insert surface is in

contact with the entire circumference of the valve.

Reassembly

1. Spring Lower Seat

N6A0134E

N6A0135E

Valve Seat Angle

Degrees

45

°

N6A0136E

N6A0137E