Isuzu N-Series. Manual - part 316

6A-6 ENGINE MECHANICAL

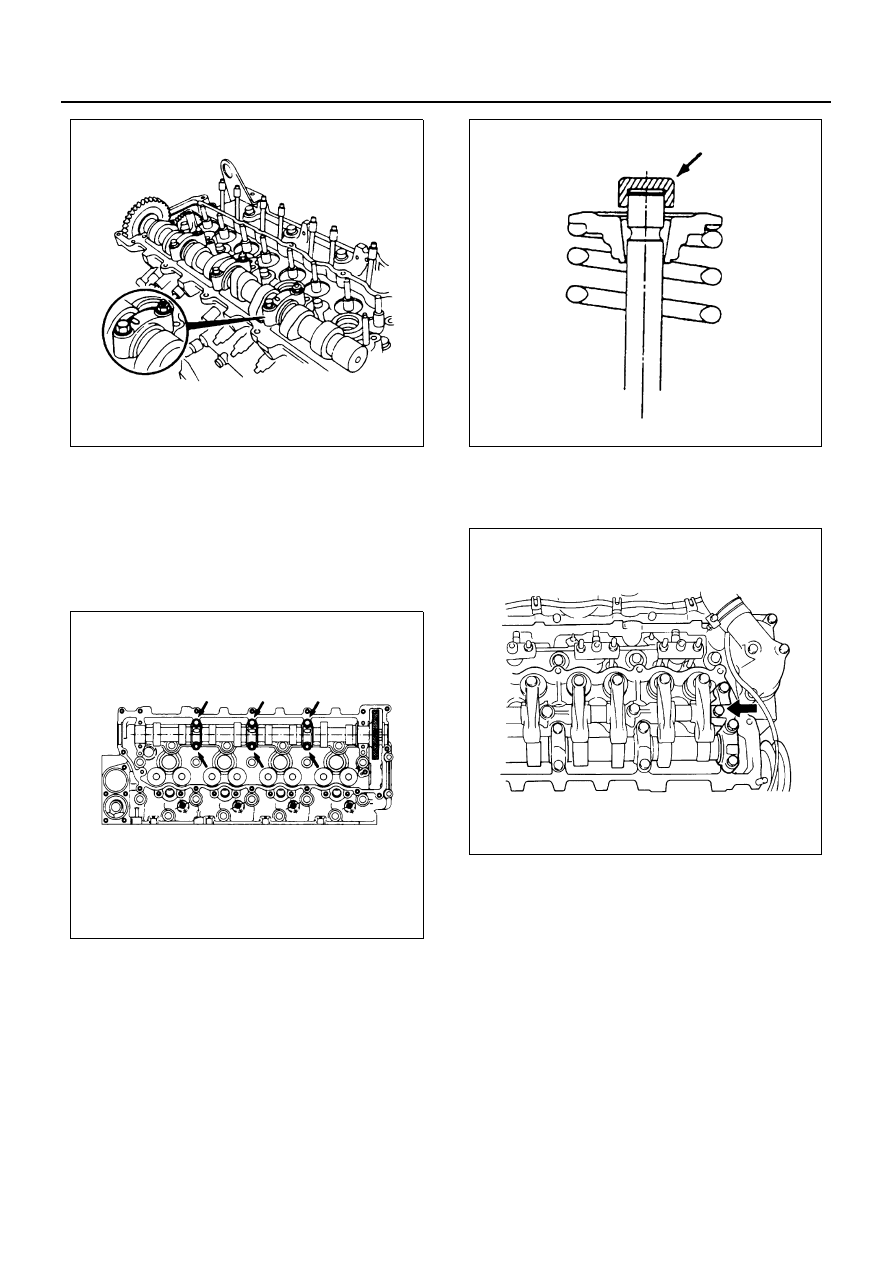

2) Apply a coat of engine oil to the bearing cap

bolt and stud threads.

3) Tighten the bearing cap bolts and studs to the

specified torque.

Tighten:

Camshaft bearing cap nut and bolt to 27 N

⋅m (2.8 kg⋅m

/ 20 lb

⋅ft)

6. Valve Cap

Apply engine oil to the inside of the valve caps and

install them to the valve stem end.

Caution:

Take sufficient care not to let valve caps fall into the

gear.

7. Rocker Arm Shaft Assembly

1) Temporarily tighten the bolts marked with the

arrow in the illustration.

2) Loosen the rocker arm adjust screws and apply

engine oil to the rocker arm roller portions.

3) Install the rocker arm assembly on the cylinder

head.

4) Tighten the rocker arm shaft bracket nuts and

bolts to the specified torque in numerical order

a little at a time as shown in the illustration.

Tighten:

Rocker arm shaft bracket nut and bolt to

• Nut (A): 27 N

⋅m (2.8 kg⋅m / 20 lb⋅ft)

• Bolt (B): 56 N

⋅m (5.7 kg⋅m / 41 lb⋅ft)

• Bolt (C): 27 N

⋅m (2.8 kg⋅m / 20 lb⋅ft)

N6A0109E

N6A0110E

N6A0111E

N6A0112E