Isuzu N-Series. Manual - part 211

HYDRAULIC BRAKES 5A-3

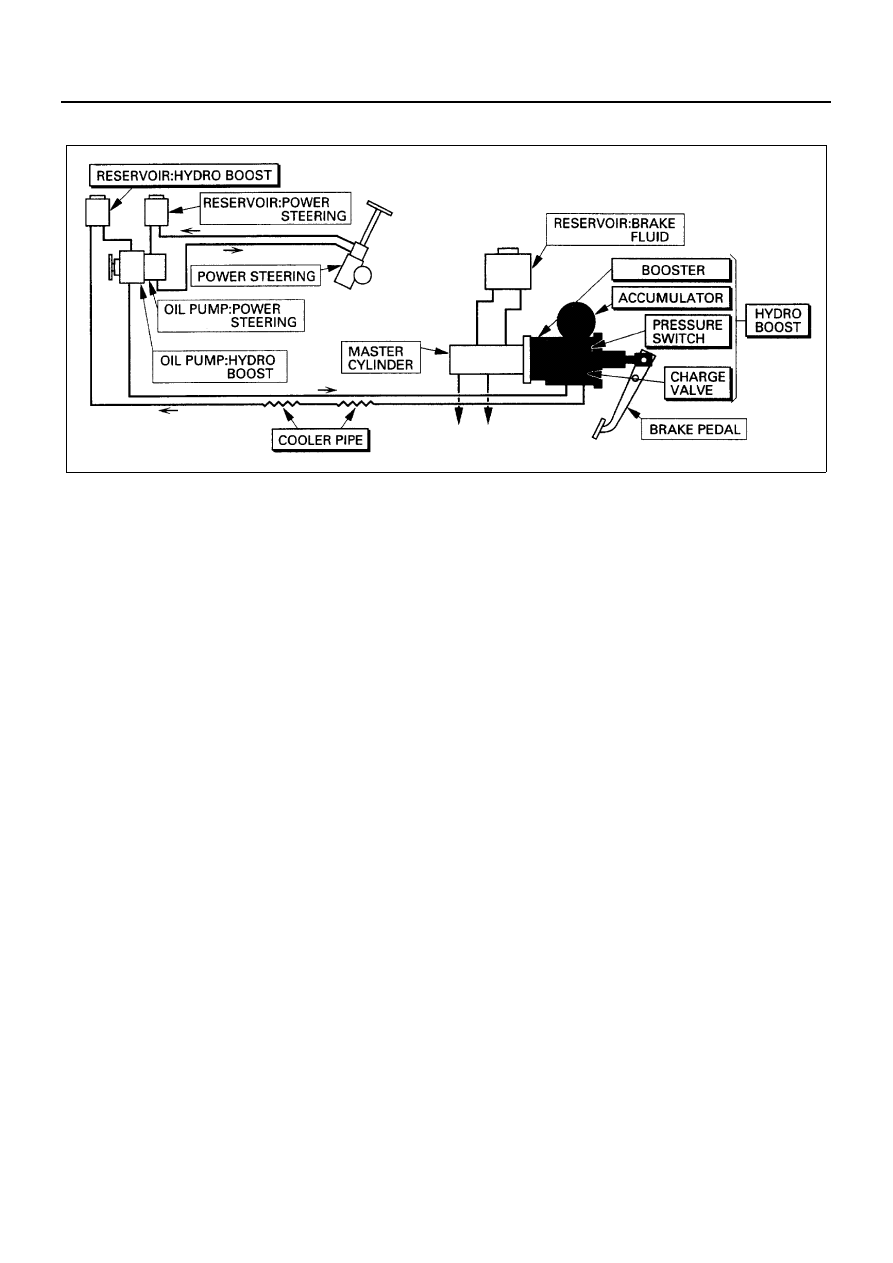

Hydraulic Booster Brake system

The hydro boost system, which functions as a brake

force boosting device that allows the brake to be operat-

ed with less force than otherwise, includes the hydro

boost, which has the booster, accumulator, charge

valve, and pressure switch in an integrated structure, a

reservoir, and a cooler pipe.

Functions of the Main Constituent Parts

Booster:

Controls the hydraulic oil ejected from the oil pump and

amplifies the force on the pedal.

Accumulator:

Accumulates the hydraulic oil under pressure for the

boosting operation after the pump stops.

Charge valve:

Performs switching operation and feeds the hydraulic oil

to the accumulator when the accumulator oil pressure

declines.

Pressure switch:

Detects that the accumulator oil pressure has declined

to the warning set pressure and operates the warning

buzzer.

Oil pump:

Is driven by the engine rotation and feeds the hydraulic

oil to the hydro boost through the piping.

Reservoir:

The pump stores the hydraulic oil for doing suction and

expulsion.

Cooler pipe:

Located before the radiator, facilitates heat radiation of

the hydraulic oil in the system piping, and inhibits an in-

crease in the temperature of the oil.

Other units relating to this system include, as shown in

the figure, the power steering, the pump and reservoir

for the power steering, the master cylinder, which re-

ceives the output of the hydro boost and activates the

brake, the reservoir for the master cylinder, and the

brake pedal that activates the booster.

The master cylinder is integrally bolted to the booster of

the hydro boost. The pump for the power steering is in-

tegrated as a tandem pump that shares the hydro boost

pump and the drive unit. But as systems, the hydro

boost and the power steering are independent of each

other, and their reservoirs are separate as well.

Booster Assembly

The hydraulic booster is a device that applies force to

the master cylinder when the brake pedal is applied. The

fluid flowing through the booster head is controlled by

brake pedal movement.

The hydraulic booster cylinder rod attaches to a piston

that connects with the spool valve. This assembly

moves when brake pedal pressure is applied. The spool

valve restricts fluid flow and builds pressure on one side

of the piston. The pressure overcomes the return spring

and moves the piston to a balanced position. As the pis-

ton moves, it pushes the cylinder rod and applies pres-

sure to the master cylinder.

A relief valve inside the pump limits the pressure to

11,770 kPa (120 kg/cm

2

/ 1707 psi). This pressure level

provides good braking without damaging the brake

pipes or hoses. When actuated, the relief valve allows

fluid to bypass the piston.

Fluid and Fluid Handling

This system uses no special fluids. However, care must

be taken to use the correct fluids. The master cylinder

and brake system uses brake fluid, while the hydraulic

brake booster pump uses power steering fluid.

N5A0045E