Isuzu N-Series. Manual - part 190

FRONT AXLE 4C-55

Inspection and Repair

Make the necessary adjustments, repairs, and part re-

placements if excessive wear or damage is discovered

during inspection.

Front Axle Tube End

Inspect the front axle case tube end sphere for crack,

wear, damage or rust. Slight rust of sphere should be

polished with a sand paper.

To check the tube end sphere for crack, use a red-check

or a magnetic flaw detector.

If a crack is found, replace the front axle case assembly.

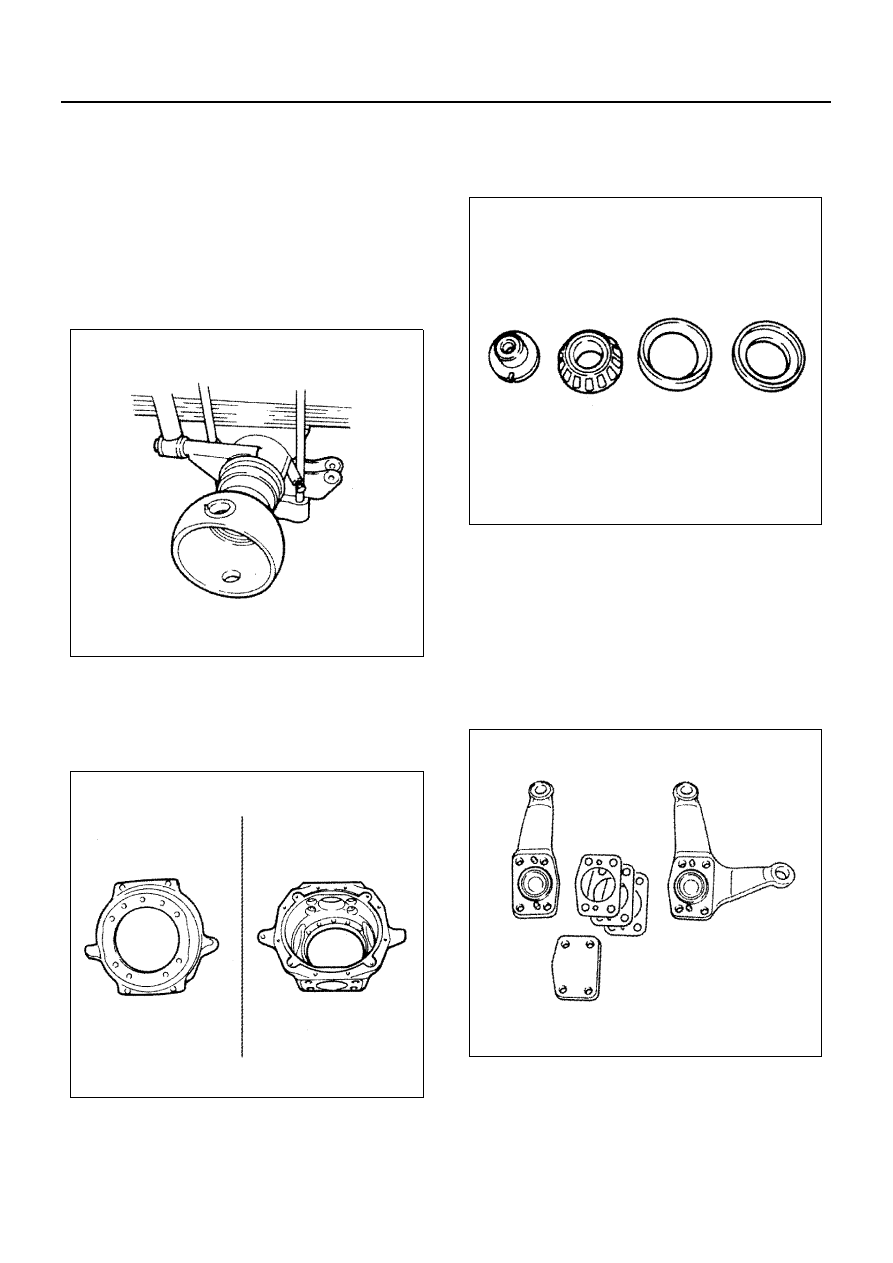

Front Axle Knuckle

Inspect the whole of the knuckle for cracks, wear or

damage using a magnetic flaw detector or red-check.

Replace the knuckle if any abnormal condition is notice-

able.

King Pin

Inspect the king pin for cracks.

Use a magnetic flaw detector or red-check.

Replace king pin, if any cracks are found.

King Pin Bearing

Inspect the bearing for wear, seizure, damage and

rough rotation.

Replace any flawed or damaged bearing.

Knuckle Arm

Tie Rod Arm

King Pin Cover

Inspect the knuckle arm, tie rod arm and king pin cover

for cracks, damage or wear.

Replace the these parts if any abnormal condition is

noticeable.

To check the arm for crack, use a visible dye-penetrant

flaw detection method or a magnetic flaw detector.

Replace the arm if a crack is found.

Front Axle Tube End Boot

Inspect the front axle tube end boot and replace if

broken. It should be replaced if even one hole or crack is

found.

Oil Seal

Inspect the oil seal, and replace it if its lip is damaged,

worn or hardened.

N4A0376E

N4A0377E

N4A0378E

N4A0379E