Isuzu N-Series. Manual - part 159

PROPELLER SHAFT 4A-11

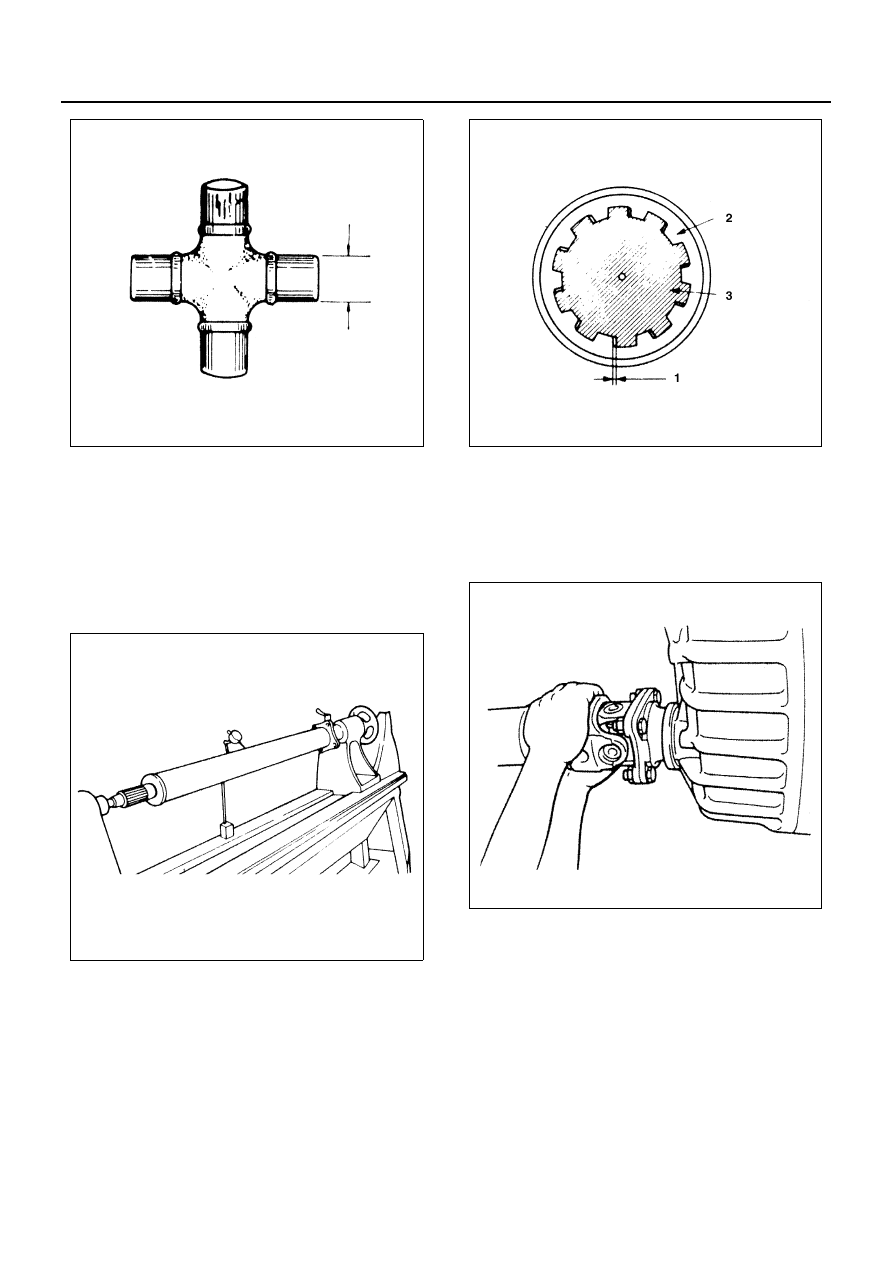

Propeller Shaft Run-Out

Support the propeller shaft at its ends and check for run-

out by holding the probe of a dial indicator agains the

center part of the shaft.

If the amount of run-out it beyond the standard value for

assembly, correct with a bench press or replace with a

new one.

Standard: 0.5 mm (0.02 in) or less

Limit: 1.0 mm (0.039 in)

Play in Splines in Normal Direction of Rotation

Check the amount of play (1) in the sleeve yoke (2) and

propeller shaft (3) splines in direction of rotation using a

pointed feeler gauge.

Standard: 0.1 mm (0.0039 in)

Limit: 0.3 mm (0.012 in)

Checking of Play of Double Cardan Joint (Front Pro-

peller Shaft Only)

1. Check the double cardan joint for play in the direc-

tion of the spider (1) shaft. When there is an exces-

sive play found, replace it as a propeller shaft

assembly.

N4A0030E

N4A0031E

N4A0032E

N4A0033E