Isuzu N-Series. Manual - part 158

PROPELLER SHAFT 4A-7

5. Center Bearing Side Nut

Tighten:

Center bearing bracket bolt to 40 N

⋅m (4.1 kg⋅m / 30 lb⋅ft)

6. Differential Side Nut

Tighten:

Differential side nut to

• M10: 63 N

⋅m (6.4 kg⋅m / 46 lb⋅ft)

• M12: 103 N

⋅m (10.5 kg⋅m / 76 lb⋅ft)

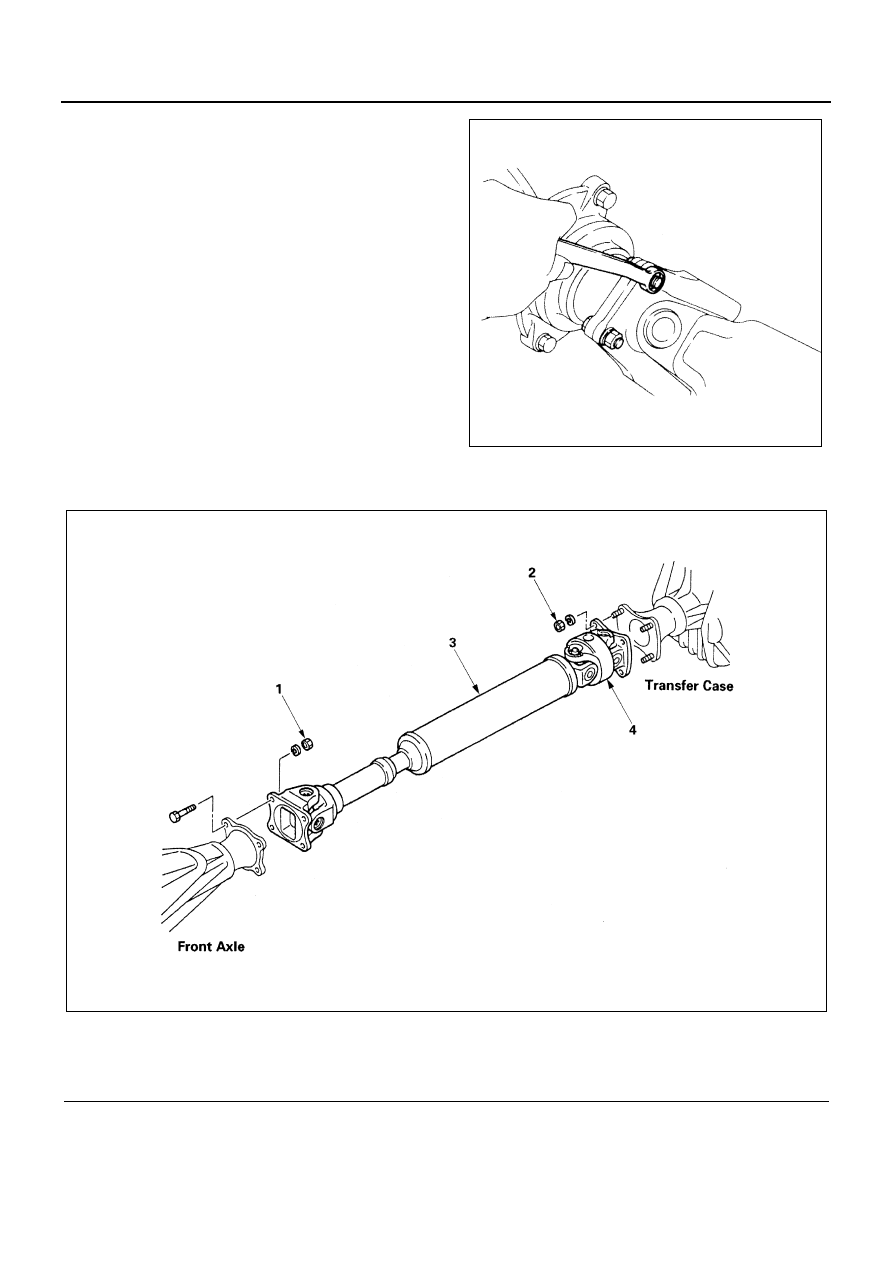

Front Drive Propeller Shaft

N4A0023E

Legend

1. Differential side nut

3. Propeller shaft assembly

2. Transfer case side nut

4. Double cardan joint

N4A0024E