Isuzu N-Series. Manual - part 18

POWER TAKE OFF 00-67

• There is discoloration, extreme wear or

pitching on the rolling body and rolling sur-

face of the needle bearing or taper roller.

• There is extreme backlash in the output

shaft and the bearing (front and rear)

Service limit; 0.2 mm (0.008 in)

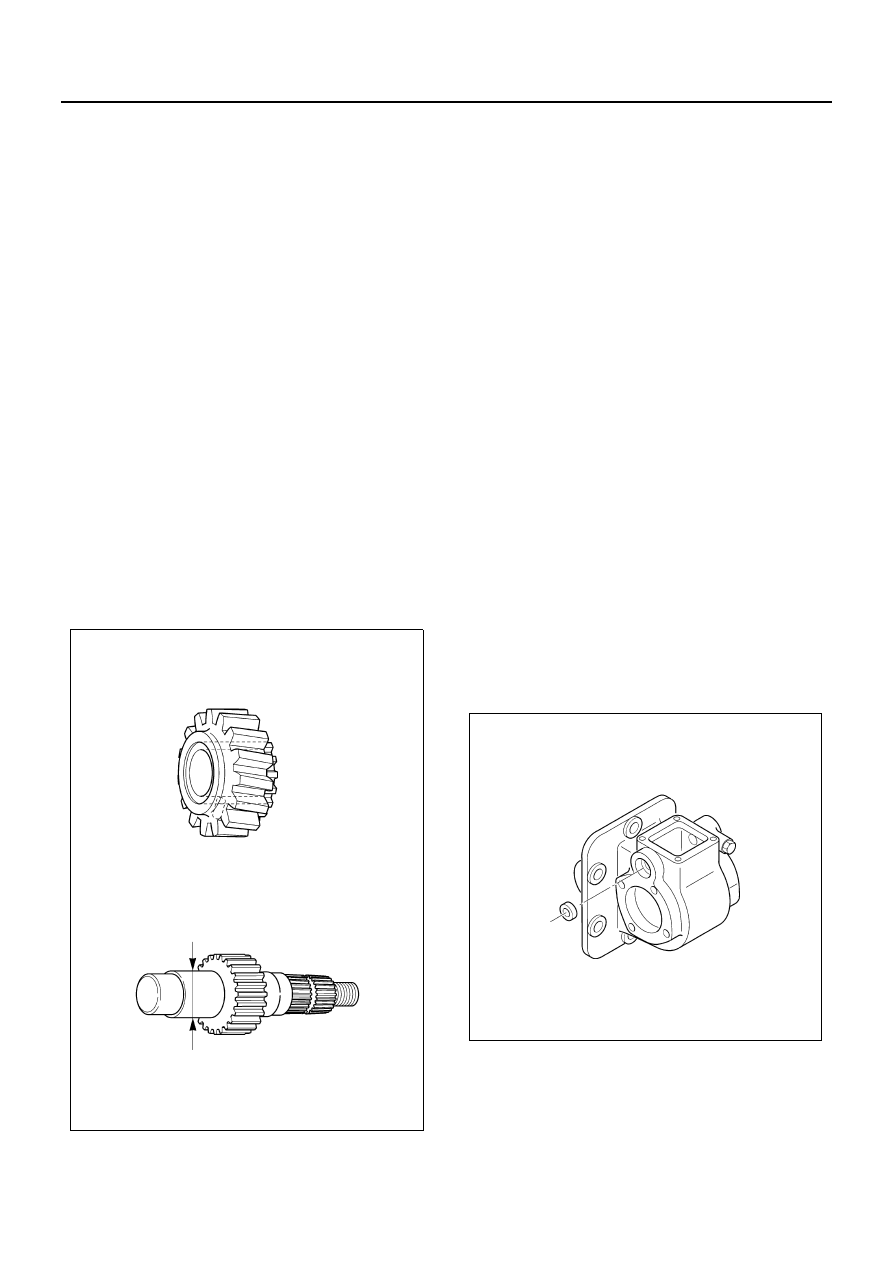

• Gears

– Check each gear. Replace it if there is extreme

fault. For minor stepped wear or rough surface,

repair it using oil stone or pencil grinder.

• Breakage, damage or wear on the cross-

section

• Wear on idle gear and shaft

Replace the idle gear (with snap ring), the

needle bearing or the taper roller bearing if

there is extreme wear.

• Gap between output shaft and output gear

(with bushing)

Service limit; 0.2 mm (0.008 in)

Replace the output gear (with bushing) if its

gap exceeds the service limit.

• Idle and output shaft

– Check for the damage or wear on the outside

surfaces of idle shaft and output shaft, wear or

damage on the spline portion, bent shaft, etc.

Replace it if the fault is extreme.

• Shift mechanism

– Check each part of shift mechanism for dam-

age, bent, stepped wear, etc. and replace it if

the fault is extreme.

• Bent or wear of shift rod

• Deformation or wear of shift arm

Thickness of shift arm

Specification; 9 mm (0.354 in)

Service limit; 8 mm (0.315 in)

• Backlash or rough movement of shift rod

and gear case

• Oil seal

– Replace the output shaft or shift rod if its con-

tact surface is damaged or deteriorated.

– Do not reuse the removed oil seal.

• Clutch

– For minor stepped wear or damage, repair it us-

ing oil stone or pencil grinder. Replace it if there

is extreme fault.

• For assembly direction of parts, refer to cross-sec-

tion diagram.

Assembly

1. Gear Case

2. Oil Seal

• Apply liquid gasket (THREE BOND 1141E) to

the circumference of oil seal and grease (BES-

CO L2 or equivalent) to the lip, and punch it into

gear case slot portion (front side).

Special tool

Oil seal installer; 5-8840-2065-0

3. Shift Rod, Shift Fork, Spring, Washer

• Put the spring and the shift fork into gear case

and pass the shift rod through them.

NPA0157E

NPA0158E