Isuzu N-Series. Manual - part 16

POWER TAKE OFF 00-59

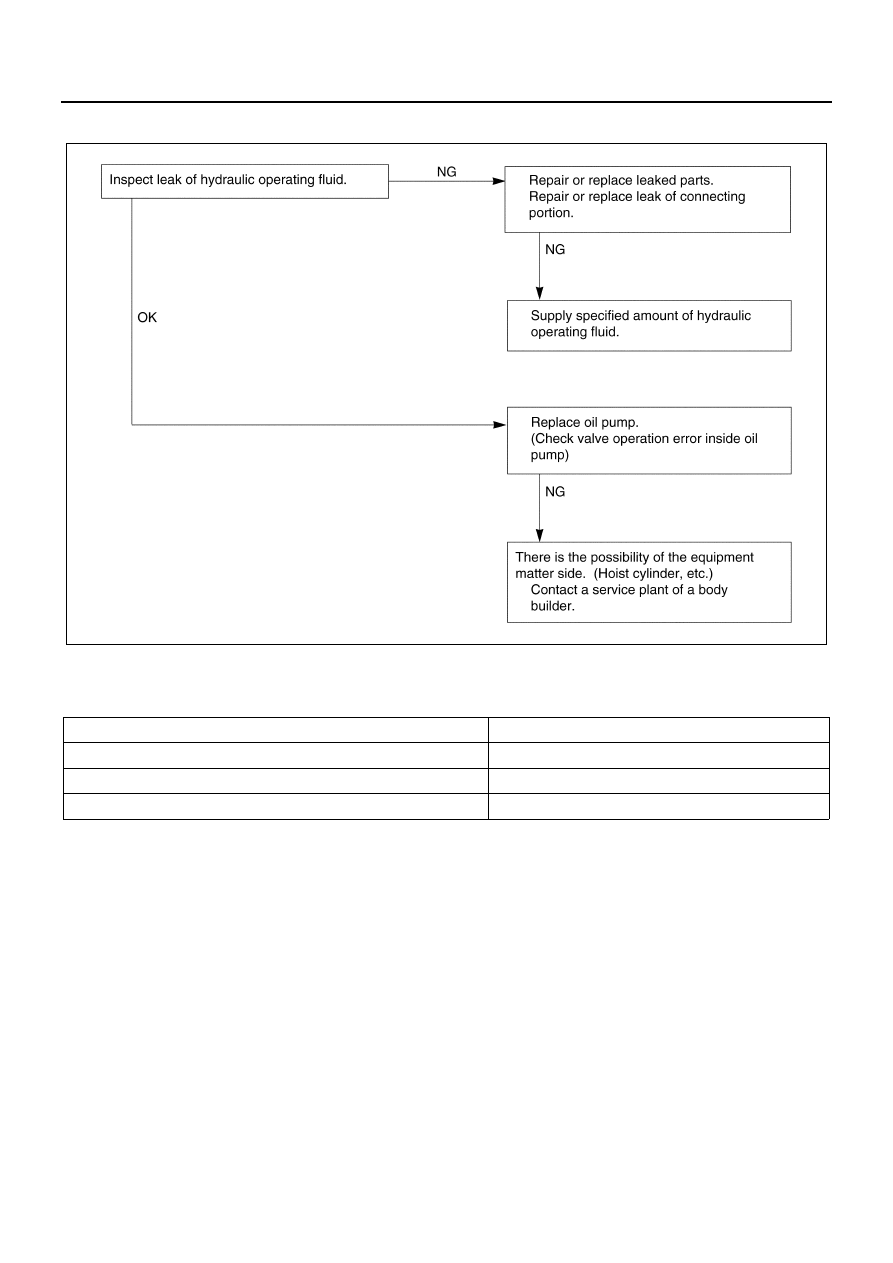

Defect 6. When a Load is Applied, The Dump Body Drops.

Main Data and Specifications

PTO with Oil Pump Assembly

Item

Specifications

Allowable maximum output torque

N

⋅m/rpm (kg⋅m/rpm)

98/1000 (10/1000)

Deceleration ratio (speed ratio for engine)

0.678

Direction of rotation (viewed from the rear of the PTO)

Clockwise rotation

NPA0181E