Isuzu N-Series. Manual - part 8

POWER TAKE OFF 00-27

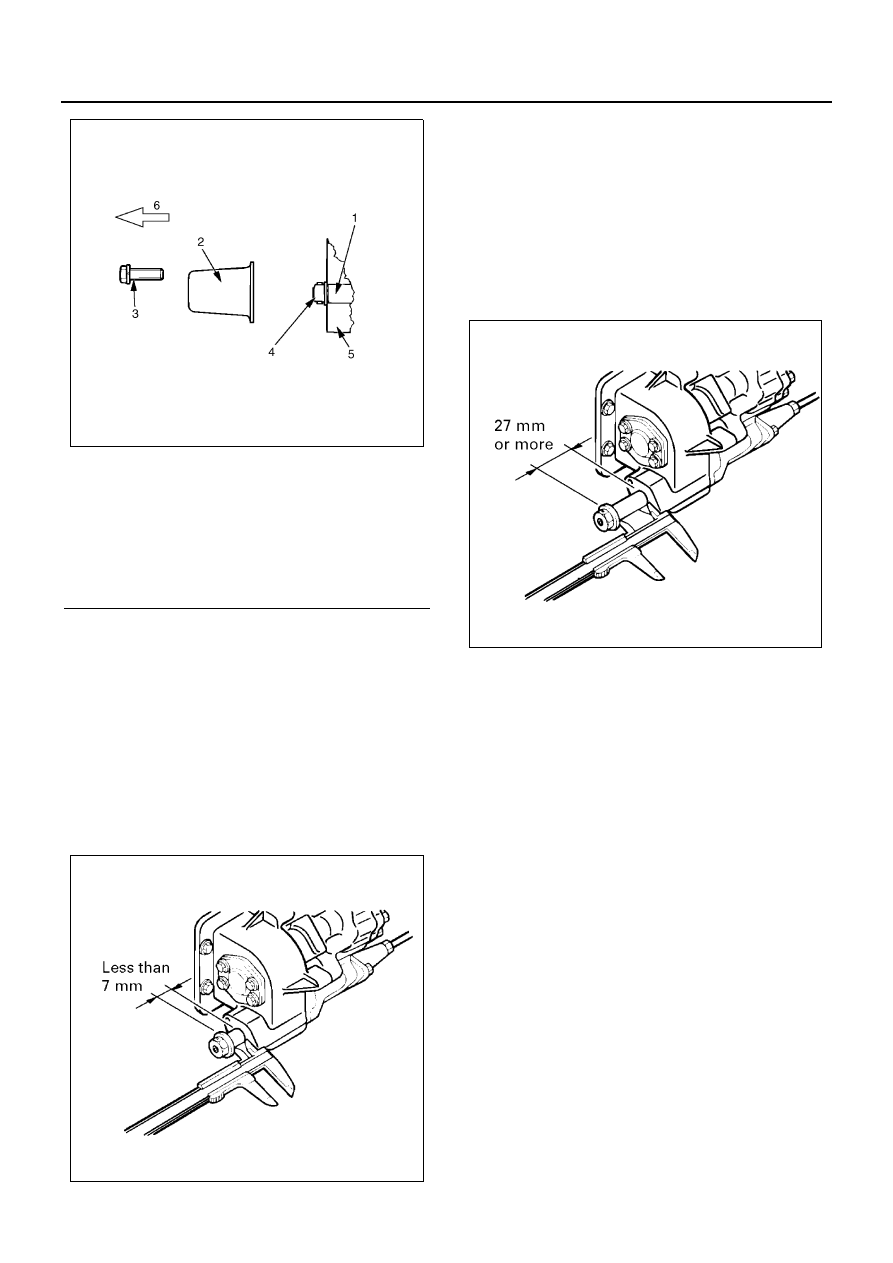

Measurement of the Amount of Spool Extrusion

(PTO Tip Portion)

1. Remove the shift cap tightening bolt of the PTO tip

portion and remove the shift cap.

2. Operate the dump lever twice or three times and

slowly set it to the “Up” position as much as possi-

ble, then firmly lock the dump lever.

3. Measure the amount of spool extrusion at “Up”

time at the PTO tip portion and check that it is a ba-

sic value.

Amount of spool extrusion: less than 7 mm (0.276 in)

4. Operate the dump lever twice or three times and

slowly set it to the “Down” position as much as pos-

sible, then firmly lock the dump lever.

5. Measure the amount of spool extrusion at “Down”

time at the PTO tip portion and check that it is a ba-

sic value.

Amount of spool extrusion: 27 mm (1.063 in) or more

Notice:

Be sure check that both amounts of spool extrusion at

“Up” and “Down” times are within basic values.

6. As a result of measurement, if the amount of spool

extrusion is within a basic value, install the shift cap

and tighten the bolt at a specified torque.

• Install the shift cap so that the groove on the lo-

cating plane can locate downward.

Tighten:

Shift cap bolt to 24 N

⋅m (2.4 kg⋅m / 17 lb⋅ft)

Notice:

If the groove is not installed facing downward, the water

intruded in the shift cap is not ejected but collected.

Rusting and freezing will cause an incorrect actuation.

Legend

1. Inner rod

2. Shift cap

3. Bolt

4. Spool extrusion portion

5. PTO tip portion

6. Truck front

NPA0056E

NPA0057E

NPA0058E