Isuzu N-Series. Manual - part 4

POWER TAKE OFF 00-11

Preparation

1. Because removal of a spare tire makes work easier

according to a truck, previously check the truck.

2. Remove the intermediate fixed clip on the truck

side between the oil pump and the oil tank of the

low-pressure side hose and set the low-pressure

hose free.

3. Prepare a cleaned hydraulic operating fluid con-

tainer (a 20 L can will do), a funnel, hydraulic oper-

ating fluid, a test hose for a special tool, and a test

hose joint.

4. Prepare the hydraulic operating fluid of about 10 L

in the cleaned hydraulic operating fluid container.

Hydraulic Operating Fluid (Turbine Oil)

Notice:

Carefully control the prepared hydraulic operating fluid

so that dust or foreign matter will not be mixed in it. Be-

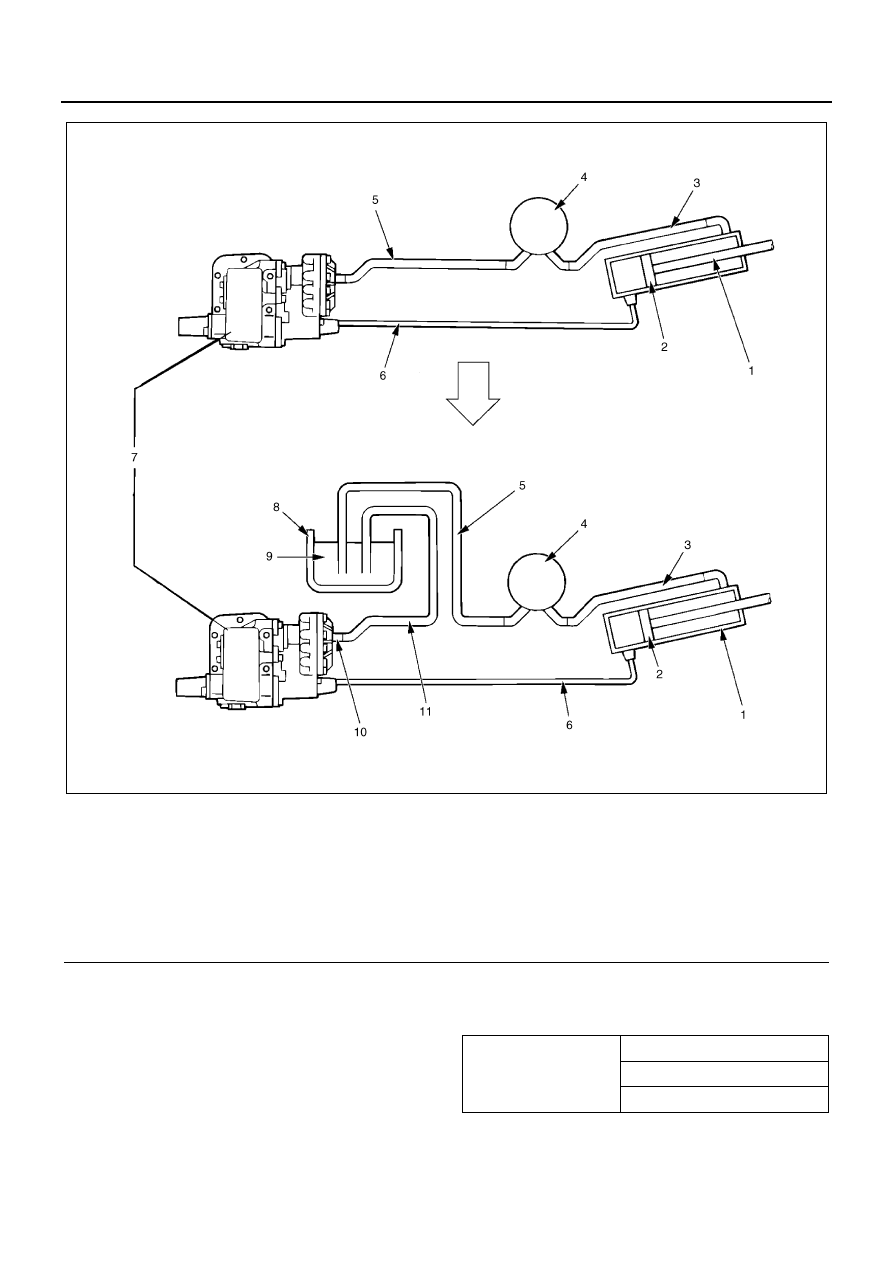

Legend

1. Hoist cylinder

7. PTO with oil pump

2. Piston

8. Hydraulic operating fluid container

3. Pipe

9. Hydraulic operating fluid

4. Oil tank

10. Test hose joint

5. Low-pressure hose

11. Test hose

6. High-pressure hose

NPA0023E

Manufactured by

ShinMaywa Indus-

tries Co., Ltd.

0 to 30

°C (86°F): VG32

20

°C (68°F) or more: VG56

less than 10

°C (50°F): VG22