Isuzu Rodeo UE. Manual - part 137

6A–37

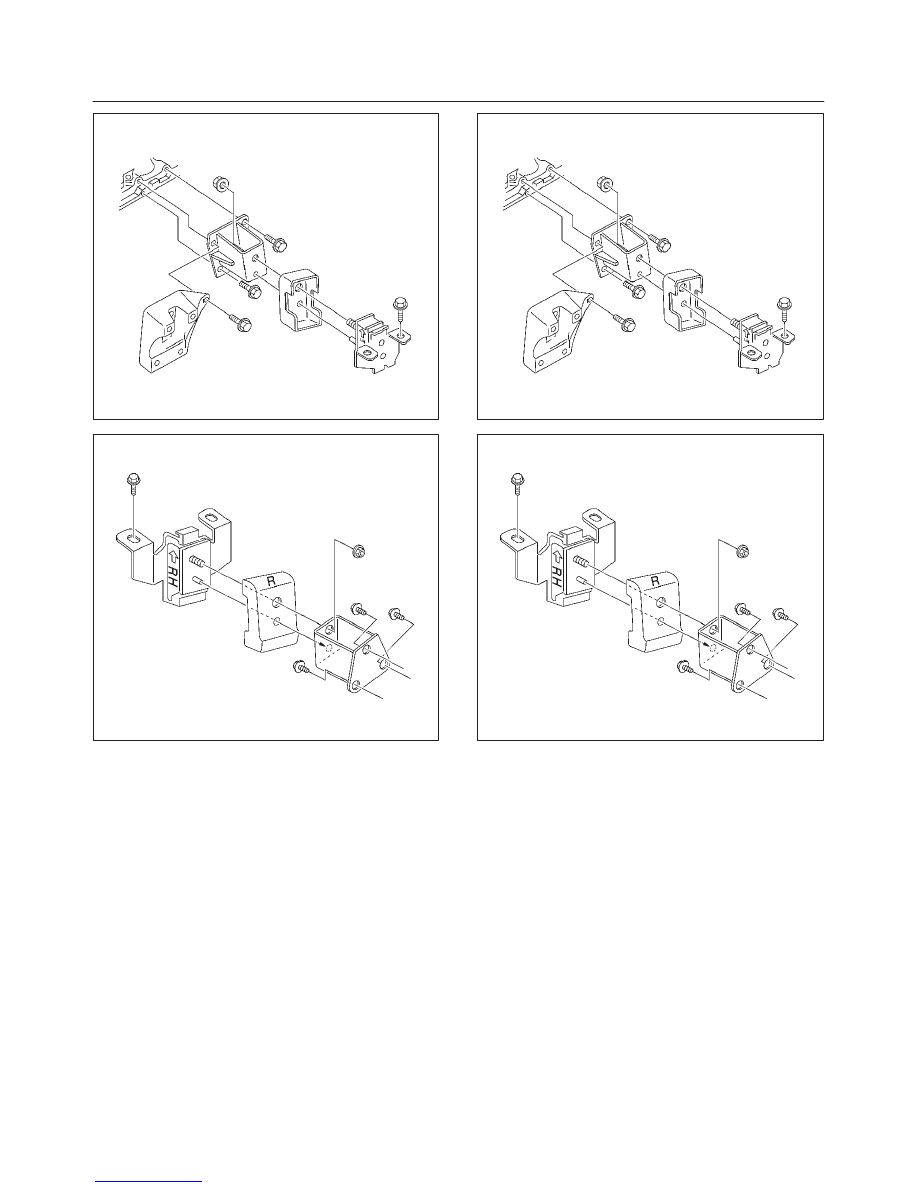

ENGINE MECHANICAL (X22SE 2.2L)

022RW005

022RW006

30. Lift up the engine assembly.

Installation

CAUTION: When assembling the engine and

transmission, confirm that dowels have been

mounted in the specified positions at the engine

side. If assembled in the condition that dowels have

not been mounted in the specified position,

transmission damage can result.

1. position the engine assembly in the engine

compartment.

2. Tighten engine mounting bolt to frame side to the

specified torque.

Torque: 41 N·m (30 lb ft)

022RW005

022RW006

3. Install harness clip behind right horn.

4. Install the radiator grille and install flasher lamp

assembly.

5. Install two heater hoses to right side panel.

6. Install radiator lower hose to engine.

7. Install engine ground cable to chassis frame.

8. Connect two chassis harness connectors to right rear

side engine room(under fuse box) and install two

harness clips.

9. Install power steering pump assembly and tighten

fixing bolts.

10. Install transmission assembly, refer to installation

procedure for Transmission section in this manual.

11. Install propeller shaft, refer to installation procedure

for Propeller section in this manual.

12. Connect canister hose next to fuel piping connector.

13. Connect two fuel pipes at right side transmission by

quick type connector.