Hyundai Santa Fe (2006 year). Manual - part 463

FL -462

FUEL SYSTEM

DTC DETECTING CONDITION

E5E34C80

Item

Detecting Condition

Possible Cause

DTC Strategy

• Voltage monitoring

Enable Conditions

• Engine running

Threshold Value

• (Case 1) VSCA real value is higher than VSCA

target value by more than 5%.

• (Case 2) VSCA real value is lower than VSCA

target value by more than 7%.

• (Case 3) Variable swirl valve operating motor is

mechanically stuck during operation

• (Case 4) Variable swirl valve operating motor is

mechanically stuck during learning ’closing’ process.

Diagnostic Time

• (Case 1,2,3) 1 sec.

• (Case 4) 3 sec.

Fuel cut

NO

EGR Off

(Case1,2)

:

NO

(Case3,4)

:

YES

Fuel Limit

NO

Fail Safe

Check

Lamp

NO

• Swirl valve opened at

variable swirl control

actuator failure

• Variable swirl valve

shaft stuck

• Variable swirl valve link

device problem

• Variable swirl valve position

sensor component

SPECIFICATION

E5DFC840

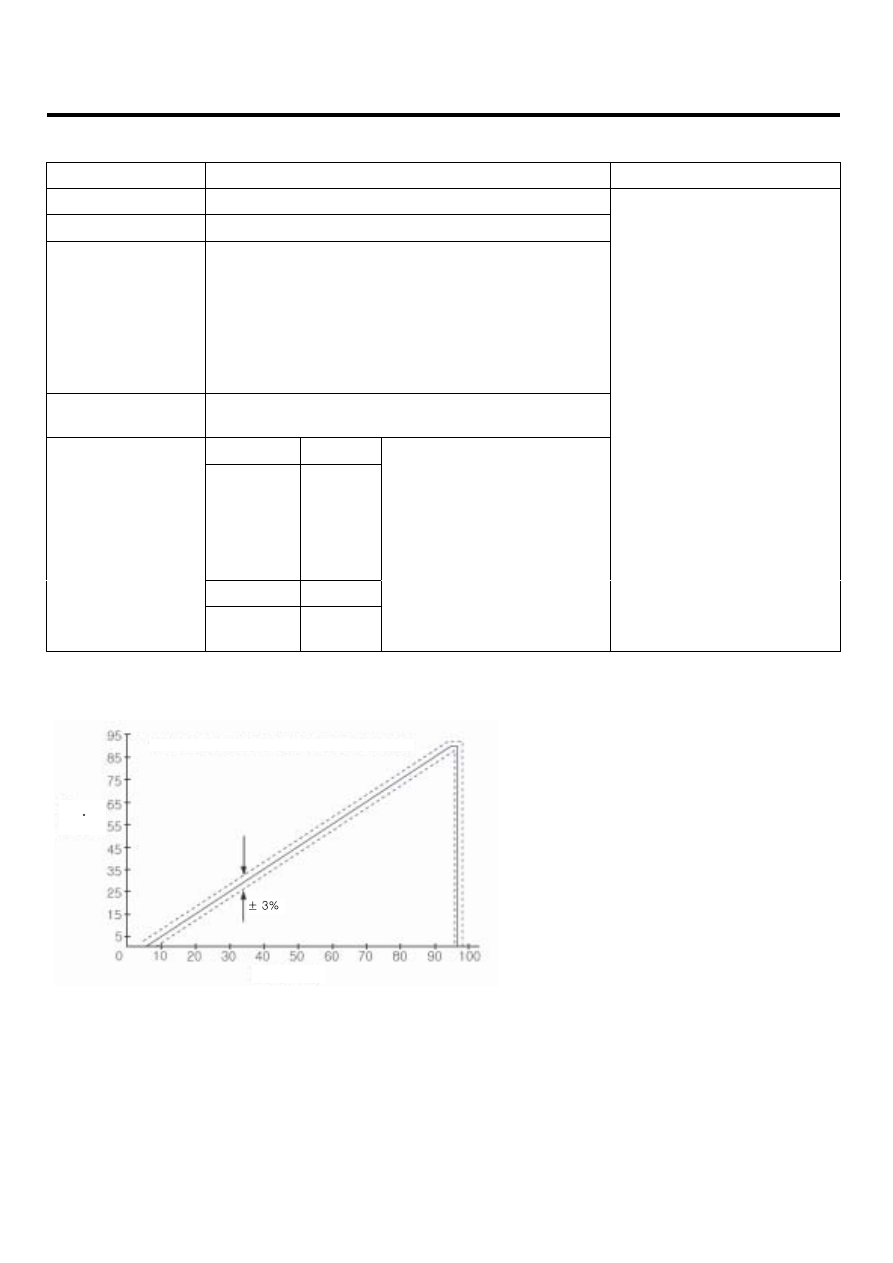

Variable swirl control actuator characteristic curve

Degree

[ ]

Duty [%]

LFIG510A