Hyundai Santa Fe (2006 year). Manual - part 415

FL -270

FUEL SYSTEM

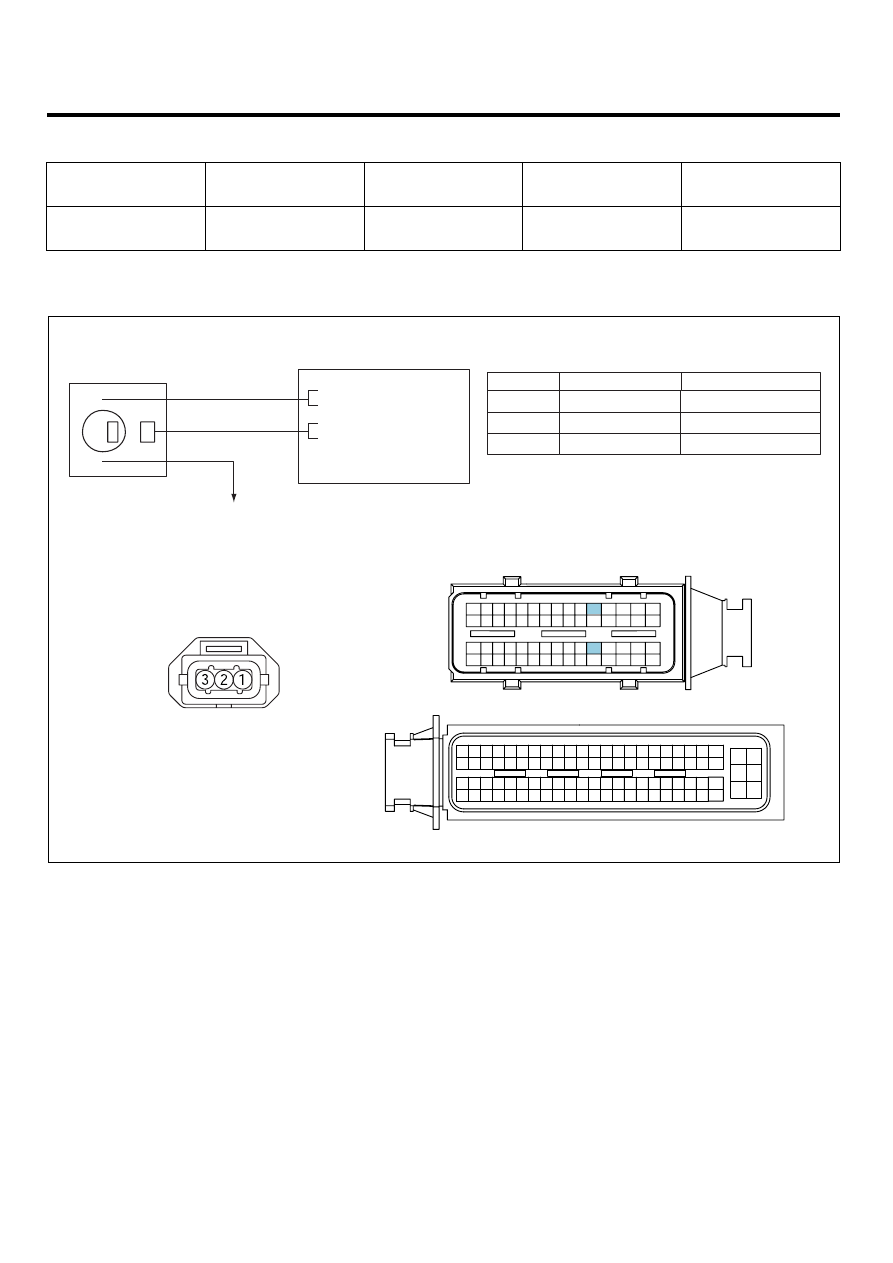

SPECIFICATION

E7EC0A4A

Sensor Type

Output Signal

Characteristic

Air Gab

Low RPM Minimum

Detecting Voltage

High RPM Minimum

Detecting Voltage

Hall effect type

0V~5V Digital signal

output

1.25mm

below 2.0V

above 3.8V

SCHEMATIC DIAGRAM

E9AA72A7

CMPS

C210

ECM (C230-A)

CMPS (C210)

1

2

ECM C230-A (50)

CMPS Signal

Battery Voltage

3

ECM C230-A(20)

GND

Main Relay

20 - GND

3

2

50 - CMPS

[Bank 1] Signal

1

[CIRCUIT DIAGRAM]

[HARNESS CONNECTORS]

[CONNECTION INFORMATION]

Terminal

Connected to

Function

Main Relay

ECM

C230-A

C230-K

1

2

4

3

6

5

8 7

12

13

16

17

18

23 22

20

21

19

27 26 25 24

28

29

30

14

9

10

11

15

33 32 31

34

37

41

42

40 39 38

35

36

43

44

47 46

49 48

50

53

56

58 57

54

51

52

55

59

60

45

1

30 29

31

32

38

39

36

37

35

33

34

40

42 41

46 45 44 43

48 47

50 49

2

3

4

6

5

8

7

12 11 10 9

13

14

15

18 17

19

16

22

25

27 26

23

20

21

24

28

51

75 74

53 52

73

79 78 77 76

80

81

83 82

84

86 85

87

89 88

90

92 91

93

94

57

69 68

70

71

64

54

55

56

61

58

59

60

63 62

65

66

67

72

SCMFL6120L