Hyundai Santa Fe (2006 year). Manual - part 164

INDICATORS AND GAUGES

BE -117

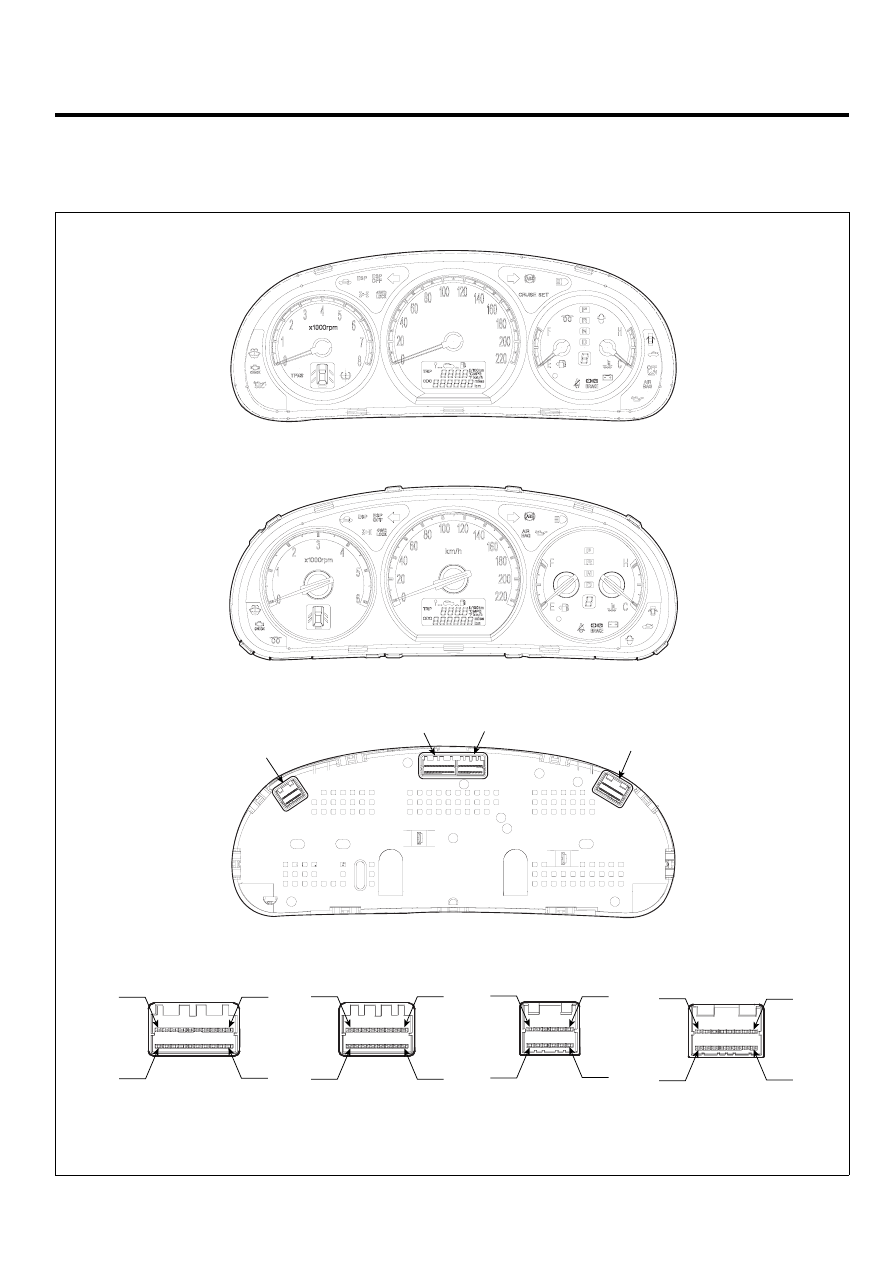

INSTRUMENT CLUSTER

COMPONENTS

E5E2EEB4

Connector C

Connector A

Connector A

Connector B

Connector C

Connector D

Connector B

Connector D

km/h

<STANDARD>

<SUPER VISION>

8

16

1

9

1

10

11

20

1

6

7

12

1

8

9

16

SCMBE6221L