Hyundai Santa Fe (2006 year). Manual - part 87

ATA -106

AUTOMATIC TRANSAXLE (A5HF1)

5.

Does "LR SOLENOID DUTY " follow the reference data?

YES

▶ Fault is intermittent caused by poor contact in the sensor’s and/or TCM(PCM)’s connector or was repaired and

TCM(PCM) memory was not cleared. Thoroughly check connectors for looseness, poor connection, bending, cor-

rosion, contamination, deterioration or damage. Repair or replace as necessary and go to "Verification of vehicle

repair" procedure.

NO

▶ Go to "Terminal&connector inspection " procedure.

TERMINAL & CONNECTOR INSPECTION

E8E9D1C6

Refer to DTC P0743.

POWER SUPPLY CIRCUIT INSPECTION

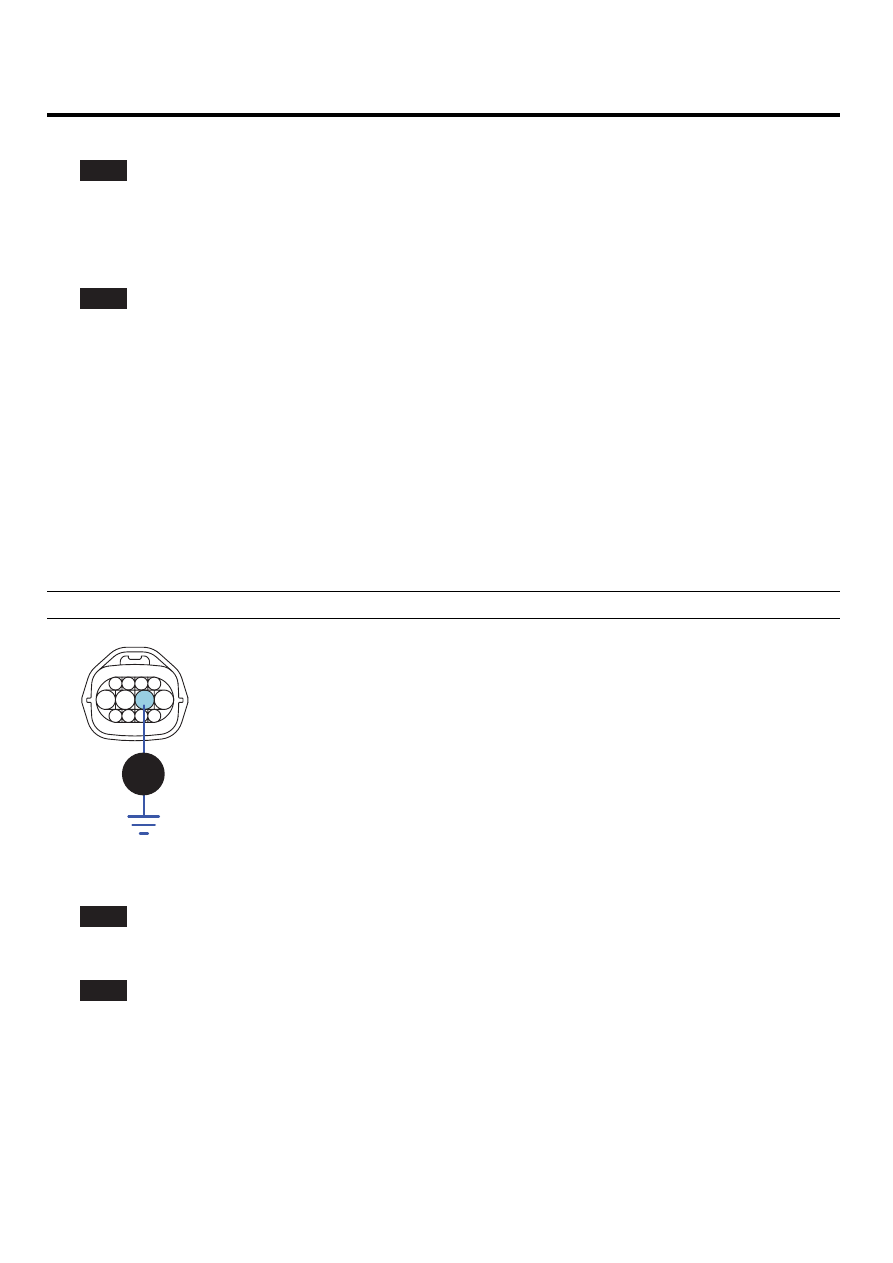

EEDFC93C

1.

Disconnect "A/T SOLENOID VALVE" connector.

2.

Measure voltage between terminal "6" of the sensor harness connector and chassis ground.

3.

Engine OFF → ON.

Specification: 12V is measured only for approx. 0.5sec

1

2

3

4

5

6

7

8

9

10

11

12

3. UD solenoid valve

4. 2ND solenoid valve

5. A/T battery

6. A/T battery

7. VF solenoid valve(-)

8. VF solenoid valve(+)

9. DCC solenoid valve

10.RED solenoid valve

11. LR solenoid valve

12. OD solenoide valve

C209

v

SCMAT6361L

4.

Is voltage within specifications?

YES

▶ Go to "Signal circuit inspection" procedure.

NO

▶ Check that A/T-20A fuse in engine room junction is installed or not blown.

▶ Check for open in harness. Repair as necessary and go to "Verification of vehicle repair" procedure.