содержание .. 16 17 18 19 20 21 22 23 ..

Geely FC. Manual part - 22

Starting and charging - Starter components

Starter components

Replacement

1. Remove engine lower left shield.

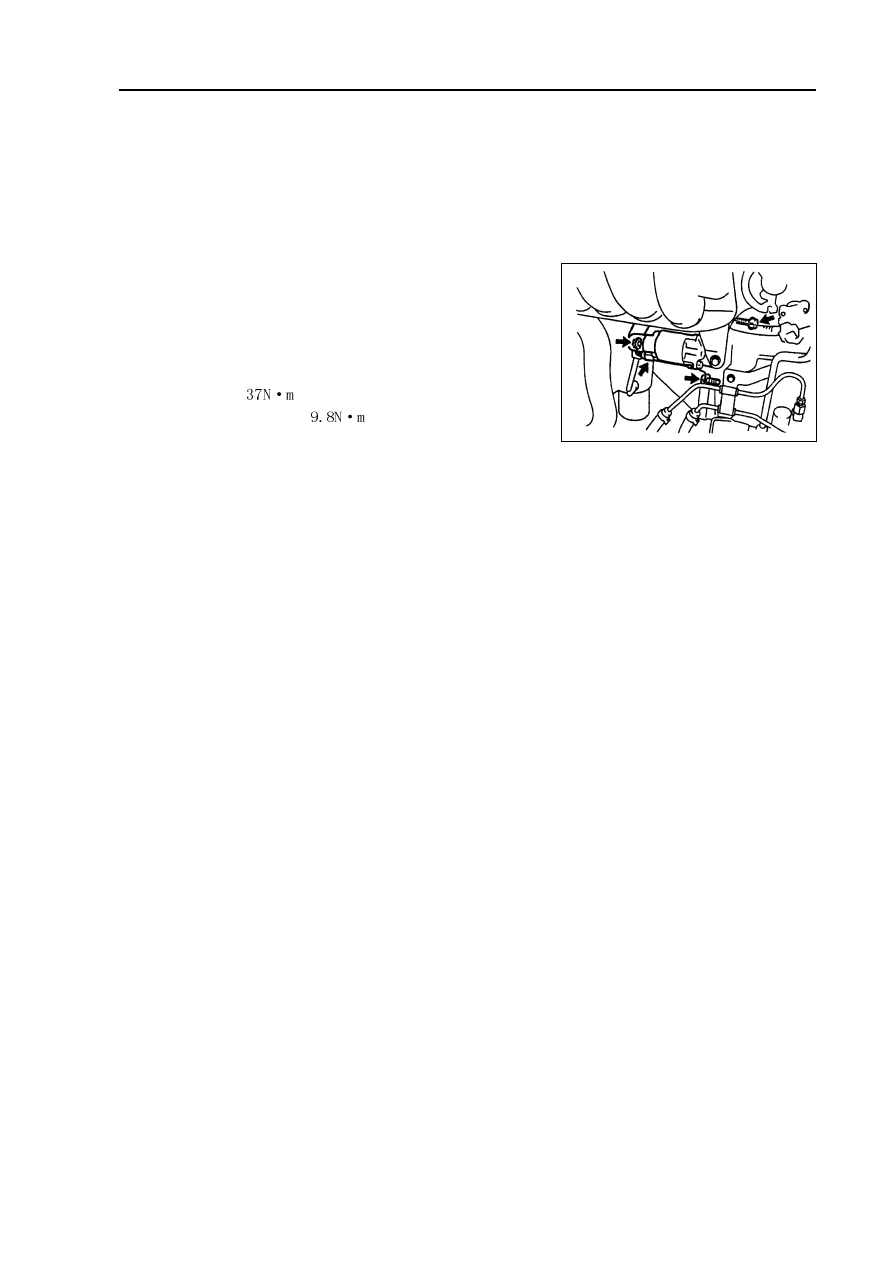

2. Remove starter components.

(b) Uncouple starter joint.

(b) Remove nuts, and uncouple starter wire.

(c) Remove 2 bolts and starter.

3. Install Starter components.

Torque:

bolt:

Wire harness:

85