Chery B11. Manual - part 77

Chery Automobile Maintenance Manual

29

V. Spark plug

check and clean of spark plug

1、

Disconnect spark plug cable.

Caution:When pulling the spark plug

cable from the spark plug,remember to

pull it with hand holding the cable cover

instead of cable itself.

2、Disassemble spark plug.

3、Check whether there is any burned electrode

or damaged insulator.Check whether the

burning trace is well-distributed.

4、Clean the carbon accumulation with steel

brush or special spark plug cleaning tool.

Blow off grits from the rippling part of spark

plug with compressed air.

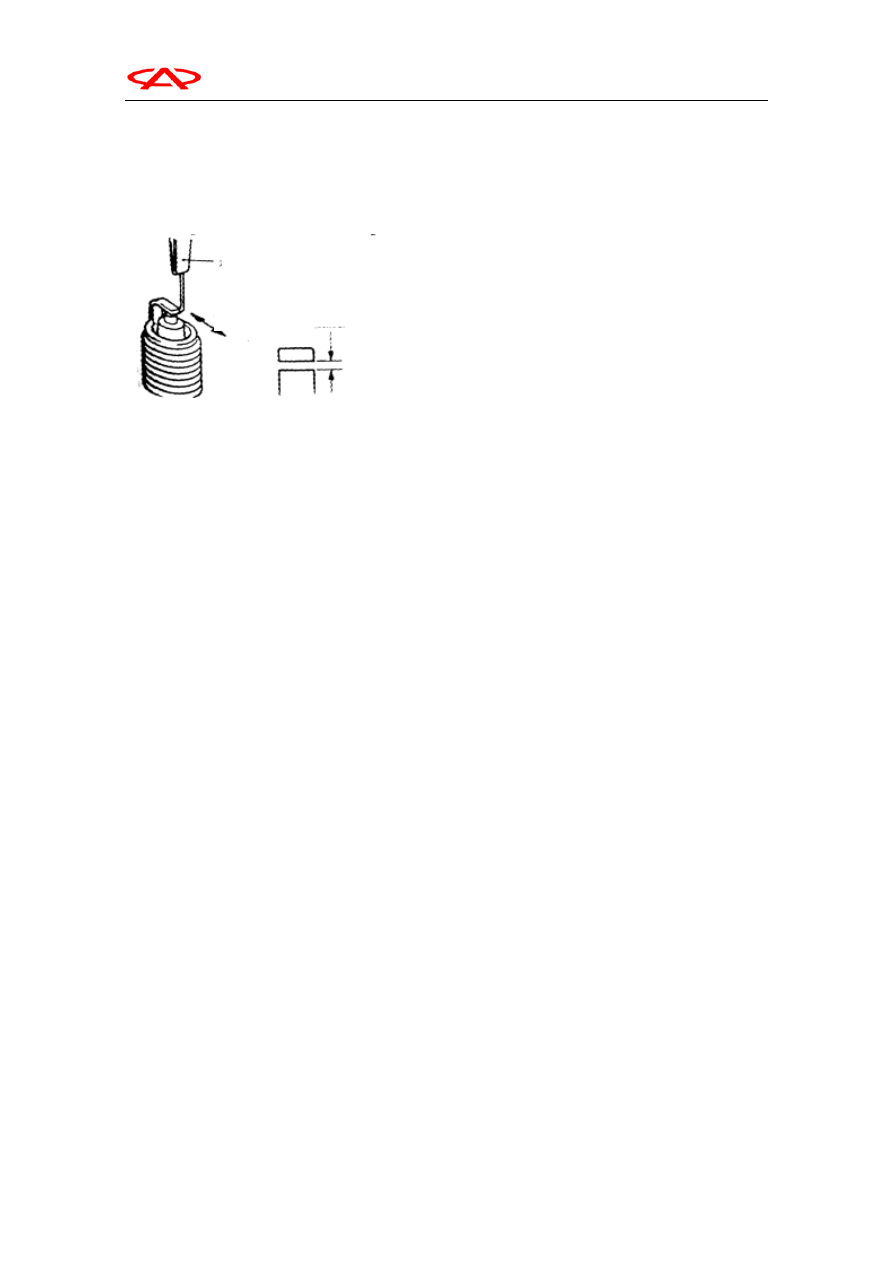

5、Check whether the spark plug clearance is in

the range of standard value with spark plug

clearance gauge.

Standard value: 1.1mm.

If the spark plug clearance is not within the

range of standard, bend ground eletrode to

adjust.

6、Clean the spark plug hole of engine.

Caution: Note not to have dirty things

outside enter the cylinder.

7、Install spark plug.

Filler gauge for spark

plug clearance

Measuring

direction