Chery B11. Manual - part 75

CHERY Automobile Maintenance Manual

23

Chapter 3 Ignition control

system

I. Engine coolant temperature

sensor

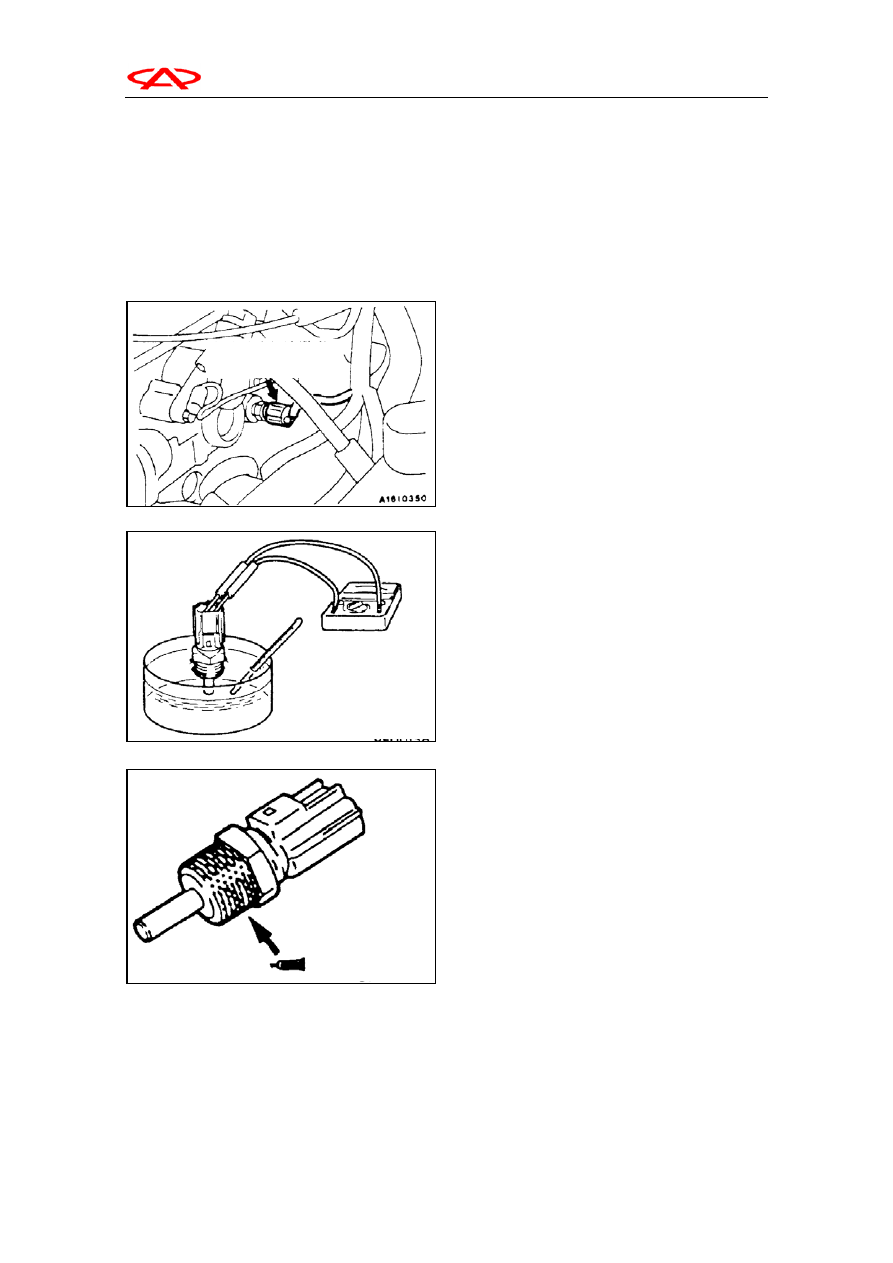

Construction feature--It is a thermal

resistance installed in the outflow terminal of

engine cooling system, which will test the water

temperature and turn it to a signal. The signal is

transmitted to ECU. The signal is input to

calculate and correct the injection driving time.

Check

Caution: Not to touch the connector (resin part)

with tools when disassembling and installation.

(1) Disassemble the engine coolant temperature

sensor.

(2)Place the temperature sensor part of the coolant

temperature sensor in hot water to check

resistance.

Standard value:

0℃,resistance is 2.1—2.7KΩ;

20℃,resistance is 2.1—2.7KΩ;

40℃,resistance is 0.9—1.3Ω;

80℃,resistance is 0.26~0.36KΩ

(3)If the resistance deviate off the standard value

too much, the sensor should be replaced.

(4)Coat sealant on the rippling part.

Regulated sealant: 3M screw nut fastening

NO.4171 or equivalent.

(5) Installation coolant temperature sensor and

tighten to the assigned torque.

Fasten torque: 29N.m.

Coolant Temperature

sensor