Chery B11. Manual - part 61

Chery·Maintenance Manual for Oriental Son

Manual Transmission

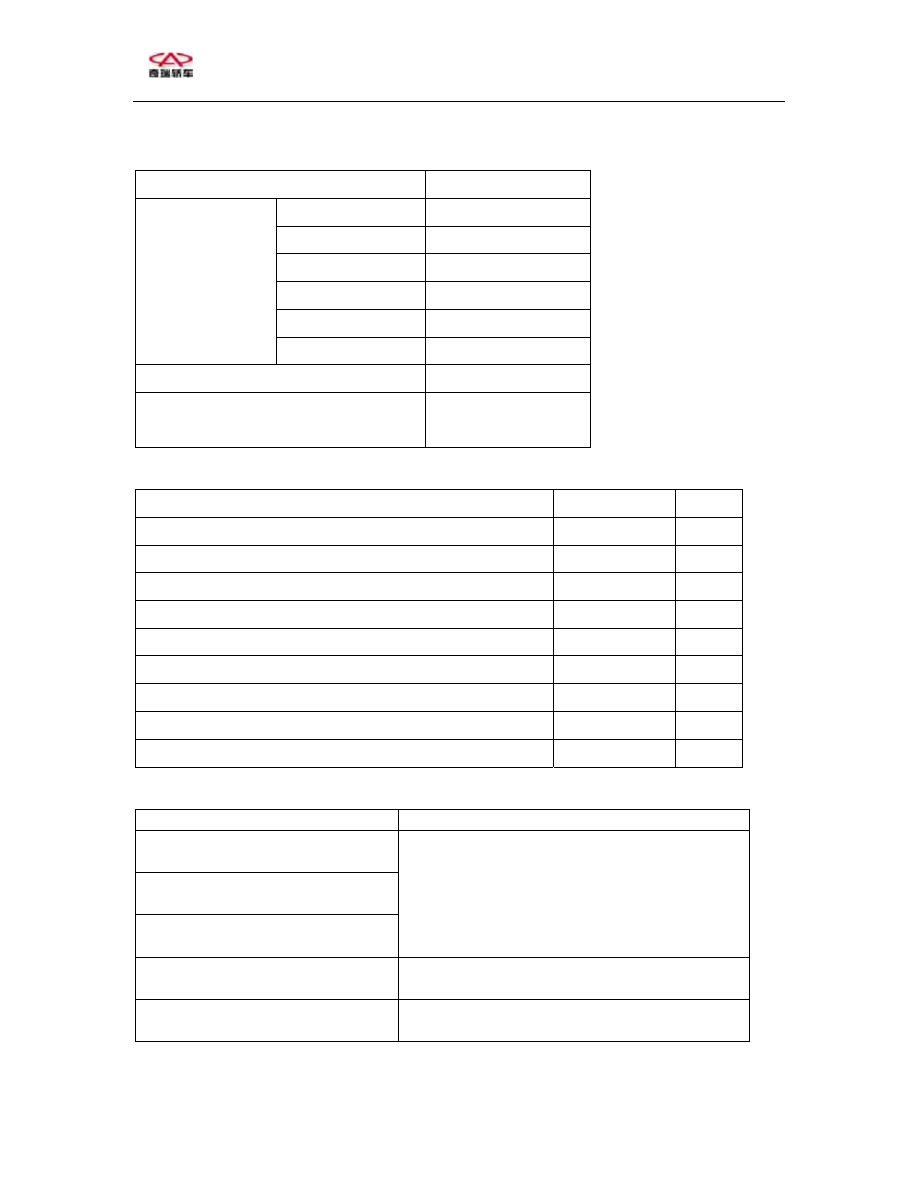

Specifications

Gearbox model

Gearbox model

F5M42

First gear

3.583

Second gear

1.947

Third gear

1.379

Fourth gear

1.000

Fifth gear

0.820

Transmission

ratio

Reverse gear

3.363

Ultimate transmission ratio

3.722

Speedometer transmission ratio

(driven/driving)

29/36

Maintenance specifications

Item

Range

Limit

Axial clearance, input shaft front bearing (mm)

-0.01~0.21

-

Axial clearance, input shaft rear bearing (mm)

-0.01~0.12

-

Axial clearance, input shaft fifth-speed gear (mm)

-0.01~0.09

-

Axial clearance, output shaft front bearing (mm)

-0.01~0.12

-

Axial clearance, output shaft rear bearing (mm)

-0.01~0.09

-

Axial clearance, output shaft third-speed gear (mm)

-0.01~0.09

-

Clearance between pinion and differential cover (mm)

0.025~0.150

-

Preload on differential cover (mm)

0.05~0.11

-

Clearance between synchronizer back and gear (mm)

- 0.05

Remarks: standard clearance=0mm

Sealant and adhesive

Item

Stipulated sealant and adhesive

Engaging surface between clutch

cover and gearbox cover

Engaging cover between control

cover and gearbox cover

Engaging cover between bottom

cover and gearbox cover

Mitsubishi sealant Part No. MD997740 or

equivalent

Air vent

3M SUPER WEATHERSTRIP NO.8001or

equivalent

Bolts of drive gear of the

differential

3M STUD LOCKING NO.4170 or equivalent

2