Chery A15. Manual - part 281

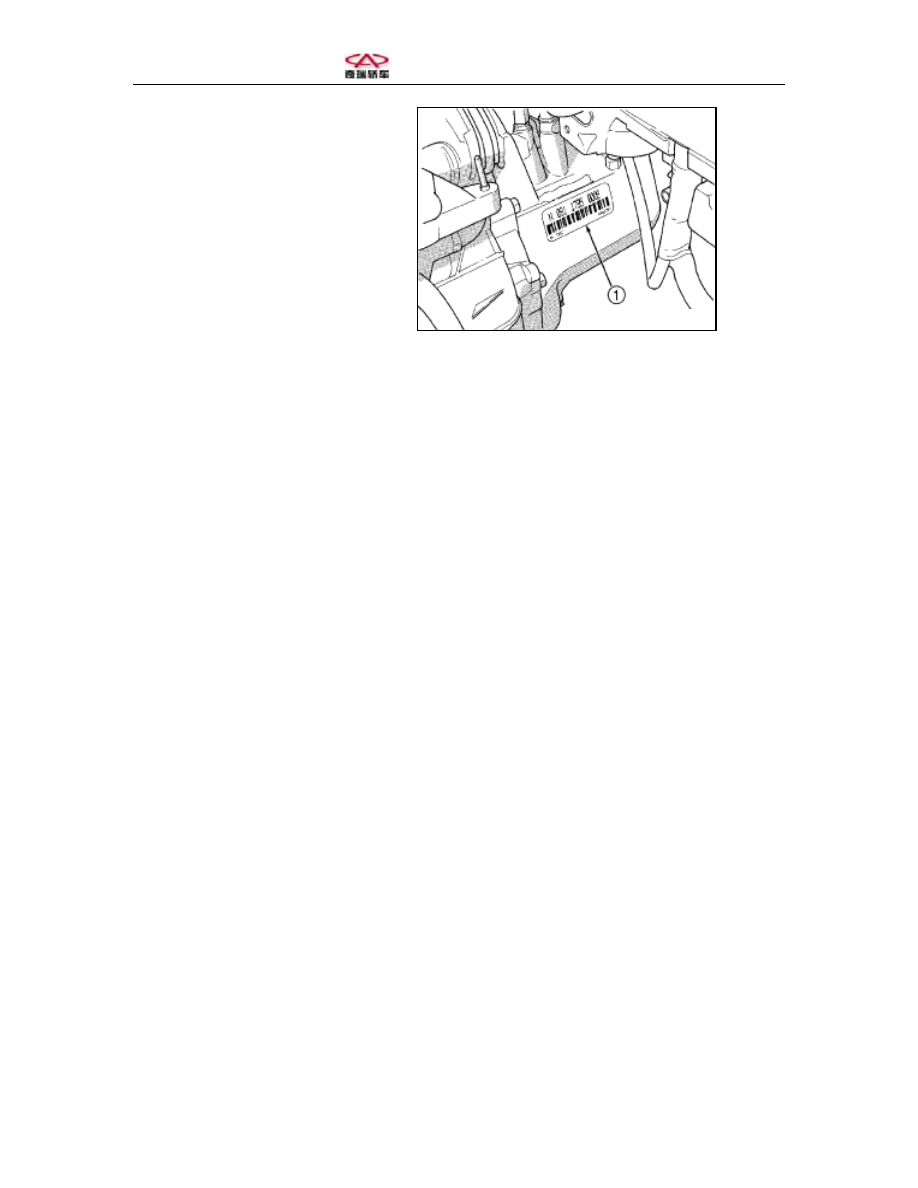

(2) Bar Code Label

Figure 3 Bar Code Label

Note: different driving ratio will be used on the gearbox when the car is traveling in

different traffic conditions. Therefore, the selected gearbox assembly components

shall be correct during maintenance, improper part number will affect the driving

ratio of the gearbox.

Caution: the gear and shaft of one gearbox are not interchangeable with those of

another gearbox; otherwise, the gearbox will not function properly.

The differential assembly is supported by a needle roller bearing.

III. Gearbox Transmission Ratio

The following is a list of various driving ratios of A15 gearbox. The status of the input

shaft brake of reverse gear is also illustrated in the list, which makes it easy to engage the

reverse gear and can reduce gear abrasion.

Driving ratio:

First gear: 3.50

Second gear: 1.95

Third gear: 1.36

Fourth gear: 0.97

Fifth gear: 0.81

Reverse gear: 3.42

Final ratio: 4.12

Reverse brake: Yes