Chery A series. Manual - part 69

REMOVAL AND INSTALLATION OF THE REAR SHOCK ABSORBER ASSY

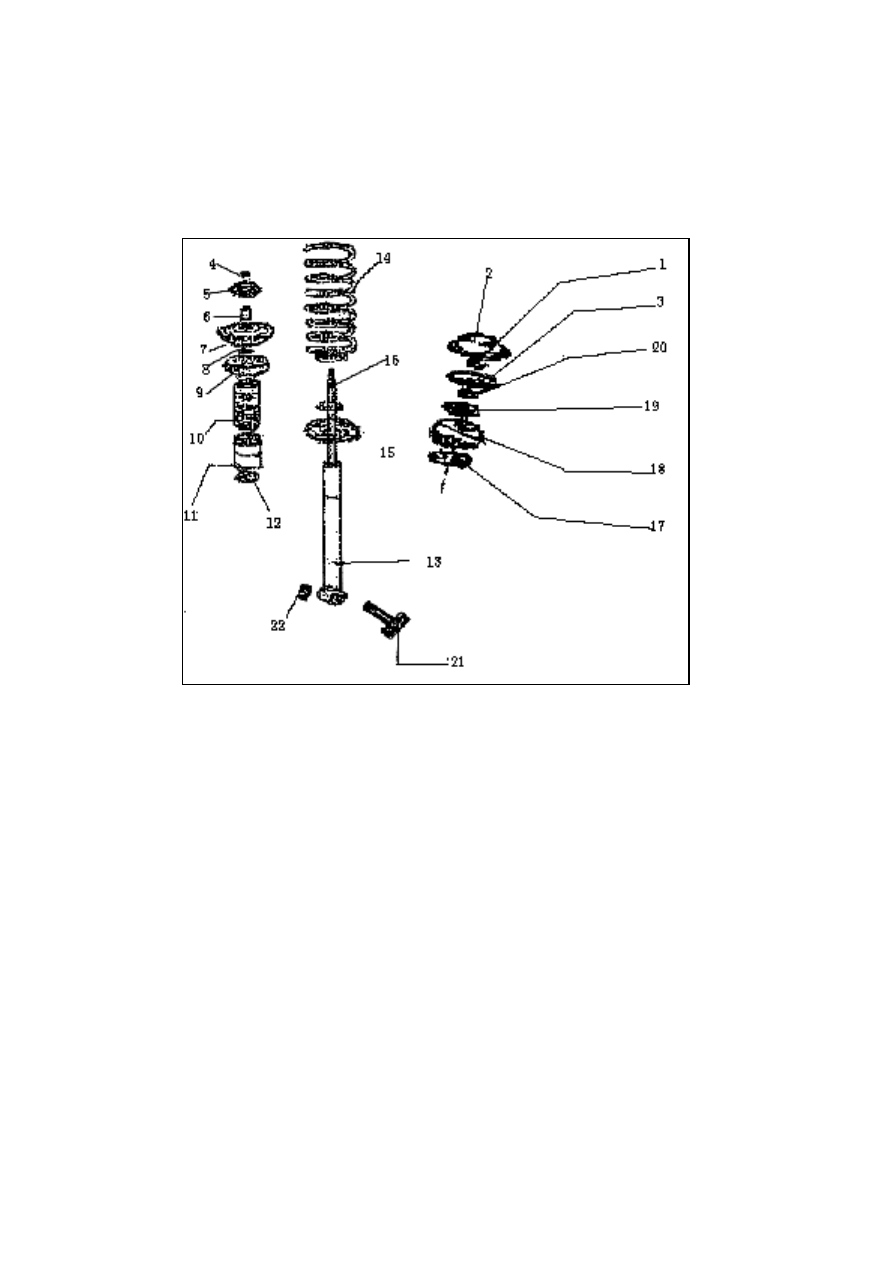

The structure of rear shock absorber assy is shown as the illustration:

Illustration. Rear shock absorber assy

1 Hexagon thin nut 15N·m 2 Rear strut upper cover 3 Belleville washer

4 Hexagon thin nut 15N·m 5 Rubber bearing block II 6 Bearing sleeve

7 Rear spring upper holder 8 Locating ring 9 Rear spring upper soft pad

10 Rear bumper block 11 Dust cover 12 Valve cap 13 Rear shock absorber assy

14 Rear coil spring 15 Rear spring bottom tray 16 Bottom tray bearing pad

17 Bowl washer 18 Rubber bearing block I 19 Support disc 20 Hexagon thin nut

25N·m 21 Bolt 22 Nut 70 N·m

M-25